Perforating regulation component

A technology for adjusting components and adjusting chains, which is applied to general parts of printing machinery, printing, printing presses, etc., can solve the problems of low automation degree of printing presses, high maintenance costs, and increased production costs, and achieves simple structure and reduced manufacturing costs. and production costs, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

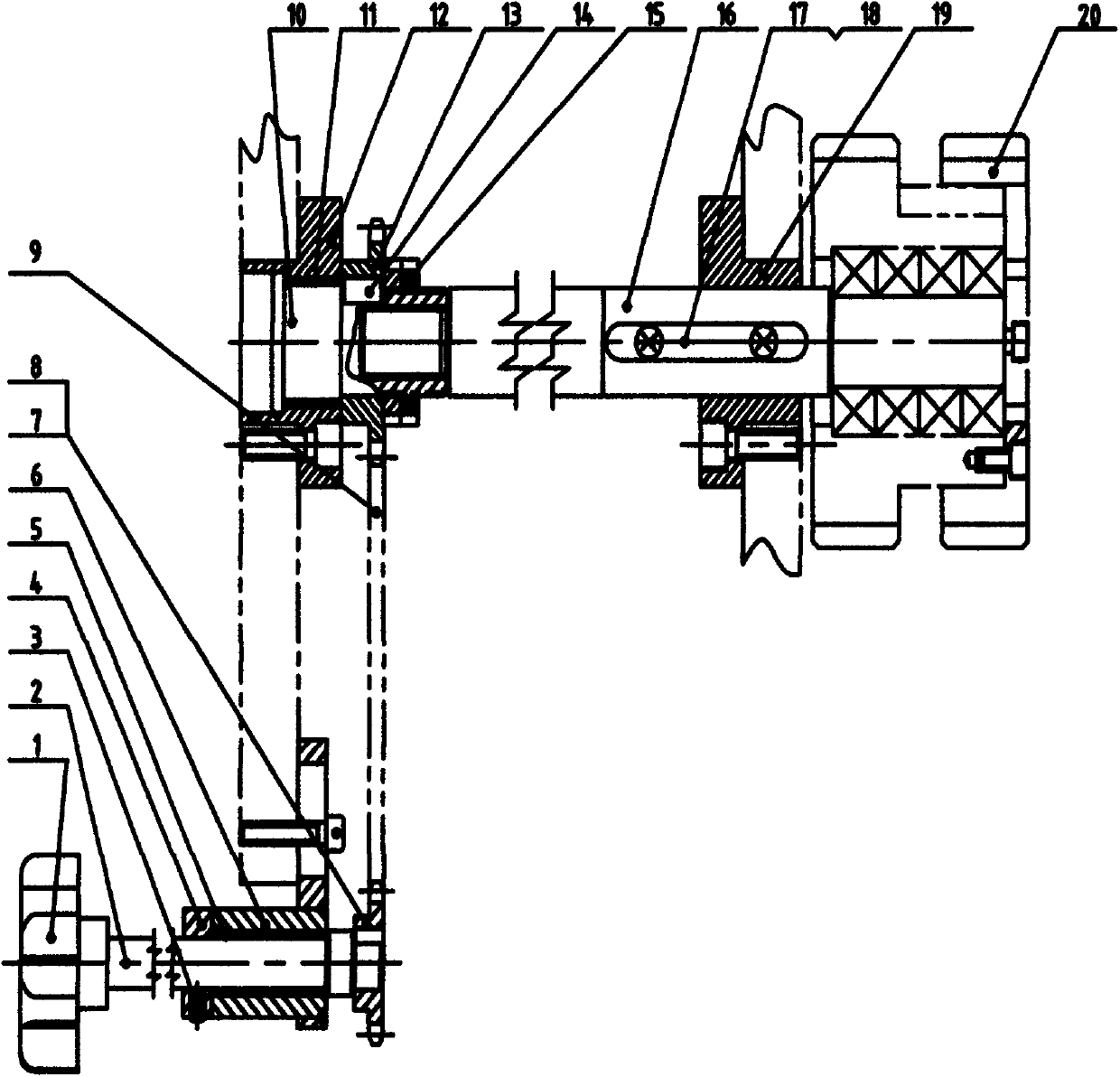

[0011] Such as figure 1 As shown, a punching adjustment assembly includes a watch handwheel 1, an adjustment sprocket shaft 2, and a punching adjustment shaft 16. One end of the adjustment sprocket shaft 2 is equipped with a watch handwheel 1, and the other end of the adjustment sprocket shaft 2 is installed with the second An adjustment sprocket 7, the adjustment sprocket shaft 2 is covered with a tight ring 4 and an adjustment sprocket seat 6, a sliding bearing 5 is set between the adjustment sprocket shaft 2 and the adjustment sprocket seat 6, and one end of the punching adjustment shaft 16 is connected with the first Two adjustment sprockets 13, the other end of the punching adjustment shaft 16 is connected with a combined gear 20, the drilling adjustment shaft 16 is connected with the second adjustment flange 19 with a guide flat key 17 and a cross recessed countersunk screw 18, the second adjustment sprocket One end of 13 is connected to the adjusting screw sleeve 10, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com