Pipe sleeve reinforcing device and method

A technology for strengthening devices and pipelines, which is applied in packaging and other directions, can solve problems such as the inability to achieve casing transportation, damage the structural safety factor, increase engineering costs, etc., and achieve the effects of saving labor costs, saving support materials, and reducing accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with specific embodiment, the present invention is further described:

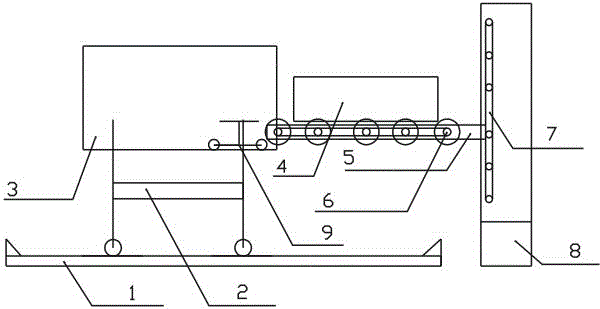

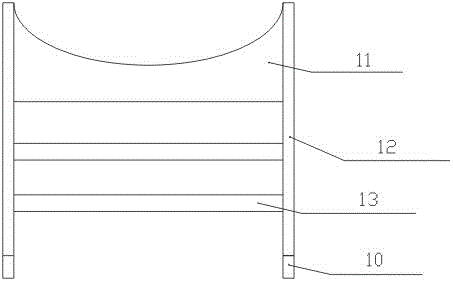

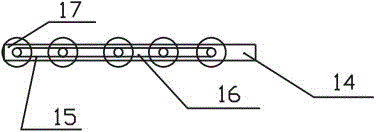

[0031] Such as figure 1 figure 2 image 3 Figure 4 The pipe casing reinforcement device shown includes a large pipe bracket 2, a small pipe bracket 5 and a small pipe bracket lifter 7, the large pipe bracket 2 is installed on the track 1, and one end of the small pipe bracket 5 is installed on the On the small pipe bracket elevator 7, the small pipe bracket 5 can be lifted vertically with the small pipe bracket elevator 7, and the large pipe bracket 2 and the small pipe bracket 5 are in adjacent positions and can be docked, wherein the A pipe jacking device 9 is also installed in the large pipe bracket 2 , and a small pipe guide rail 6 is also arranged in the small pipe bracket 5 .

[0032] In this embodiment, the large pipe bracket 2 includes a vertical H-shaped steel bracket 12 mounted on the roller 10 and a horizontal channel steel reinforcement support 13, and the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com