Manufacturing method of twisted optical fiber

A technology for twisting optical fibers and manufacturing methods, applied in manufacturing tools, glass manufacturing equipment, etc., can solve the problems of slow wire drawing speed, uncontrollable wire drawing quality, and difficult to control wire diameter thickness, so as to reduce equipment requirements, ensure optical performance, reduce The effect of production difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

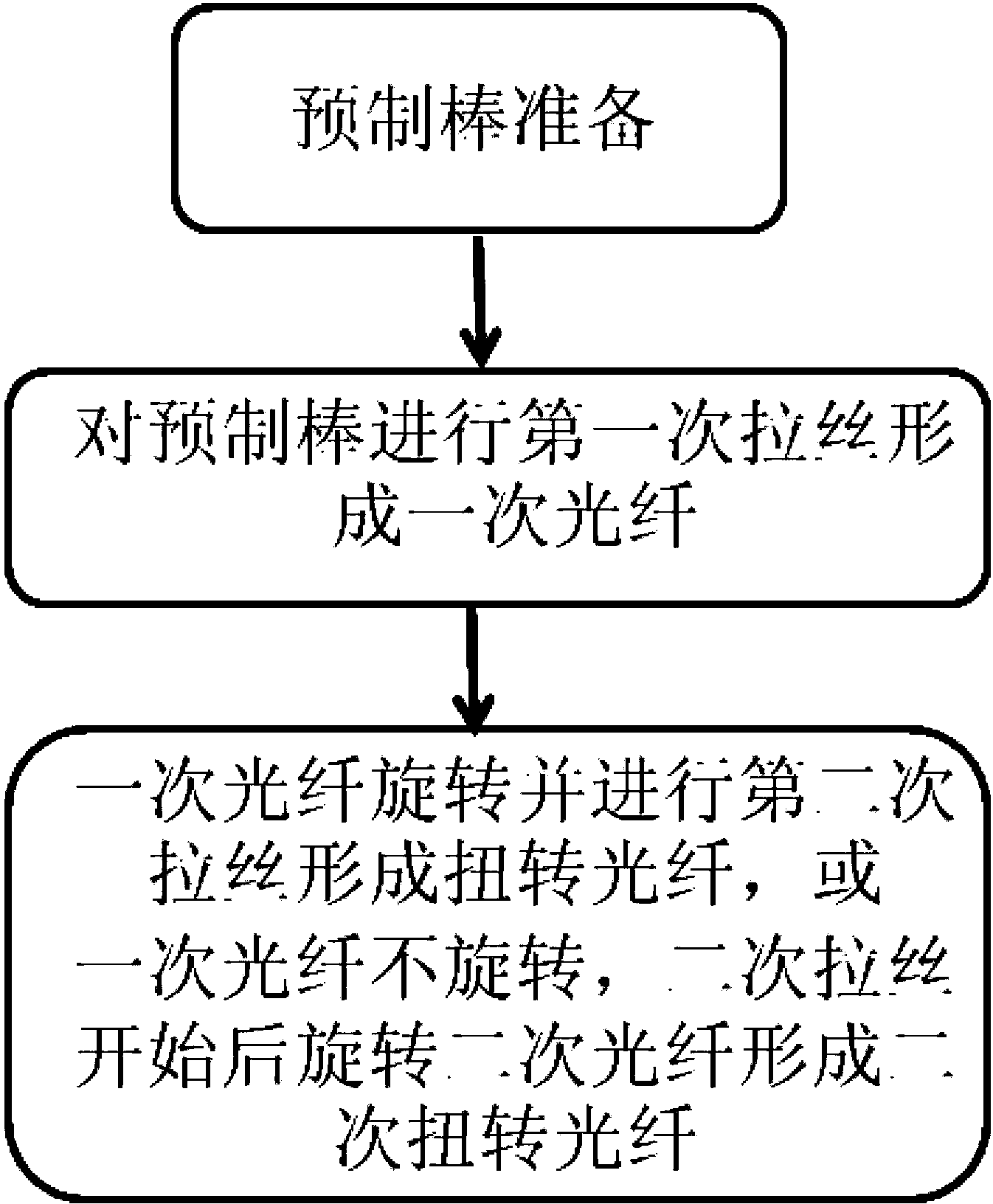

[0023] The manufacturing method of the twisted optical fiber provided by the present invention, such as image 3 shown, including the following steps:

[0024] 1) Prepare an optical fiber preform according to the conventional process. The optical fiber preform is a single-mode or eccentric optical fiber or a triple-stress or multi-stress or high birefringence polarization-maintaining optical fiber preform, and a high-birefringence polarization-maintaining optical fiber preform includes a stress double Refractive preforms and geometric birefringent preforms;

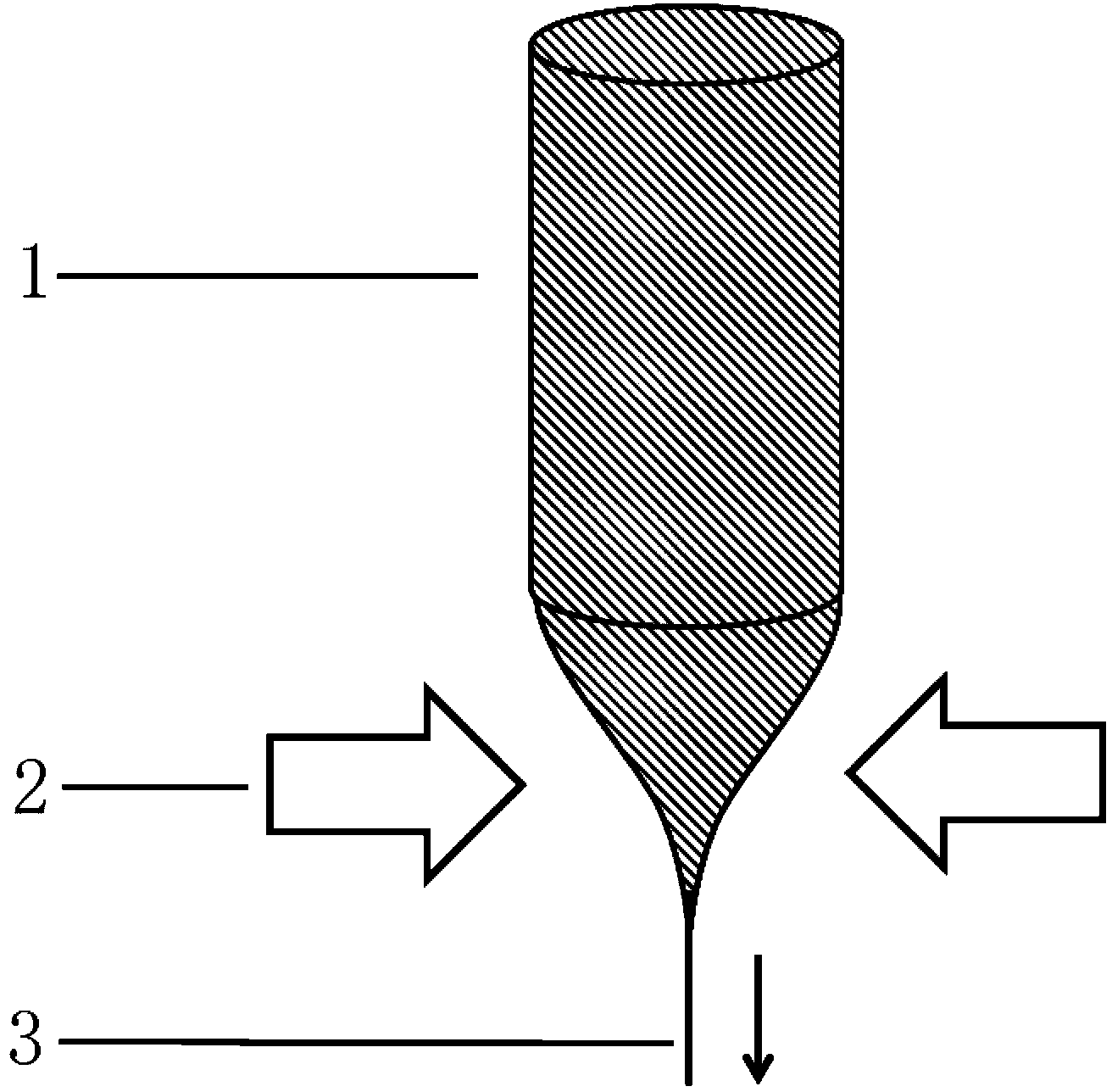

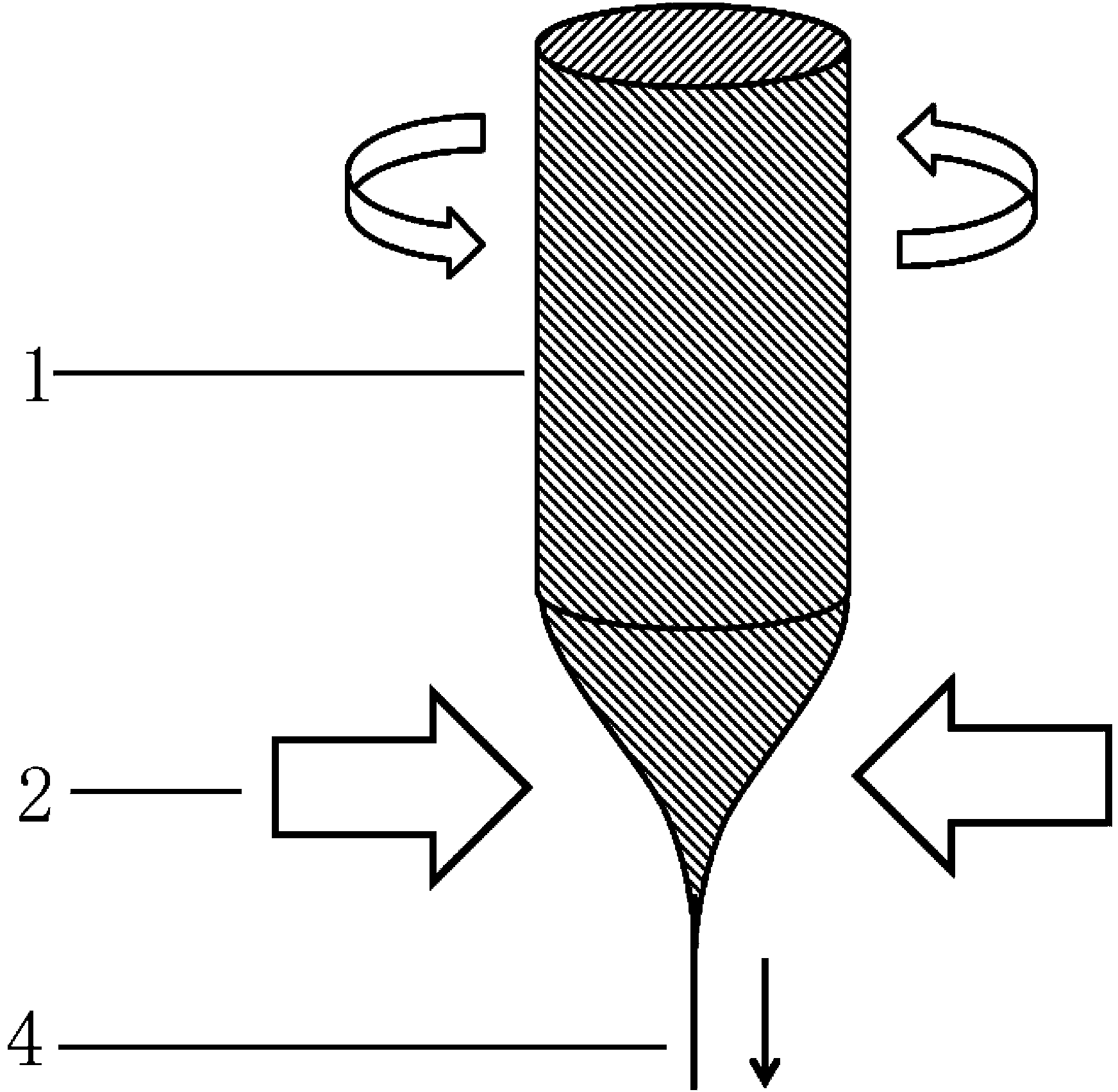

[0025] 2) use figure 1 In the traditional drawing process shown, the optical fiber preform is processed into a primary optical fiber 5, and the diameter of the primary optical fiber 5 is usually 2-20 times the diameter of the twisted optical fiber, but not limited to 20 times. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com