Metallic ink composition as well as preparation method and application thereof

A technology of metal ink and composition, applied in the field of metal ink composition and its preparation, to achieve good adhesion fastness and good covering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] According to the preparation method of the metal ink composition provided by the present invention, each component in the metal ink composition is mixed uniformly in a solvent, preferably vinyl chloride resin, metal pigment, inorganic pigment dispersant, adhesion promoter The step of uniformly mixing with the diluent comprises: (1) dispersing and dissolving the vinyl resin in the diluent to obtain a slurry containing the vinyl resin; (2) mixing the inorganic pigment dispersant with the slurry obtained in step (1) , obtain the slurry that contains vinyl acetate resin and inorganic pigment dispersant; (3) metal pigment and the slurry obtained in step (2) are mixed uniformly, obtain the slurry that contains vinyl acetate resin, inorganic pigment dispersant and metallic pigment; (4 ) mixing the adhesion promoter and the slurry obtained in step (3) uniformly to obtain the metal ink composition.

[0035] According to the preparation method of the metal ink composition provide...

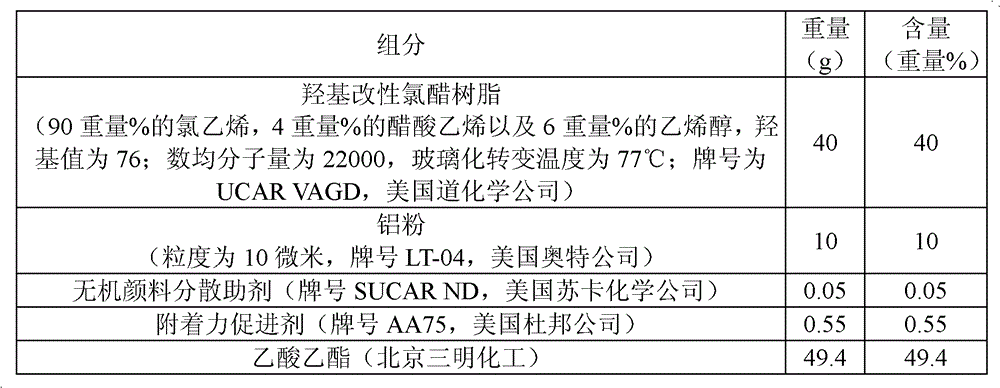

Embodiment 1

[0046] This example is used to illustrate the metal ink composition provided by the present invention and its preparation.

[0047]

[0048] At 25°C, using a high-speed mixer with a stirring speed of 800rpm and a stirring time of 20min, dissolve and disperse 40g of vinyl acetate resin in 49.4g of ethyl acetate and mix well, then add 0.05g of inorganic pigment dispersion aid and continue to stir and mix evenly Then add 10g of aluminum powder, continue to stir and mix evenly; then add 0.55g of adhesion promoter, continue to stir and mix evenly to obtain metal ink composition X1.

Embodiment 2

[0050] This example is used to illustrate the metal ink composition provided by the present invention and its preparation.

[0051]

[0052] At 25°C, using a high-speed mixer, the stirring speed is 500rpm, and the stirring time is 50min. Dissolve and disperse 35g of vinyl acetate resin in a mixture of 19g of acetone and 19.45g of methyl isobutyl ketone. After mixing evenly, add 1.5g of inorganic pigment dispersion aid agent, continue to stir and mix evenly; then add 25g of aluminum powder, continue to stir and mix evenly; then add 0.05g of adhesion promoter, continue to stir and mix evenly, and obtain the metal ink composition X2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com