Evaporation device

A technology of vapor deposition and vapor deposition of materials, which is applied in the directions of vacuum evaporation plating, sputtering plating, ion implantation plating, etc., can solve problems such as thermal deterioration, increased residual materials, and inability to obtain materials, so as to prevent thermal deterioration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

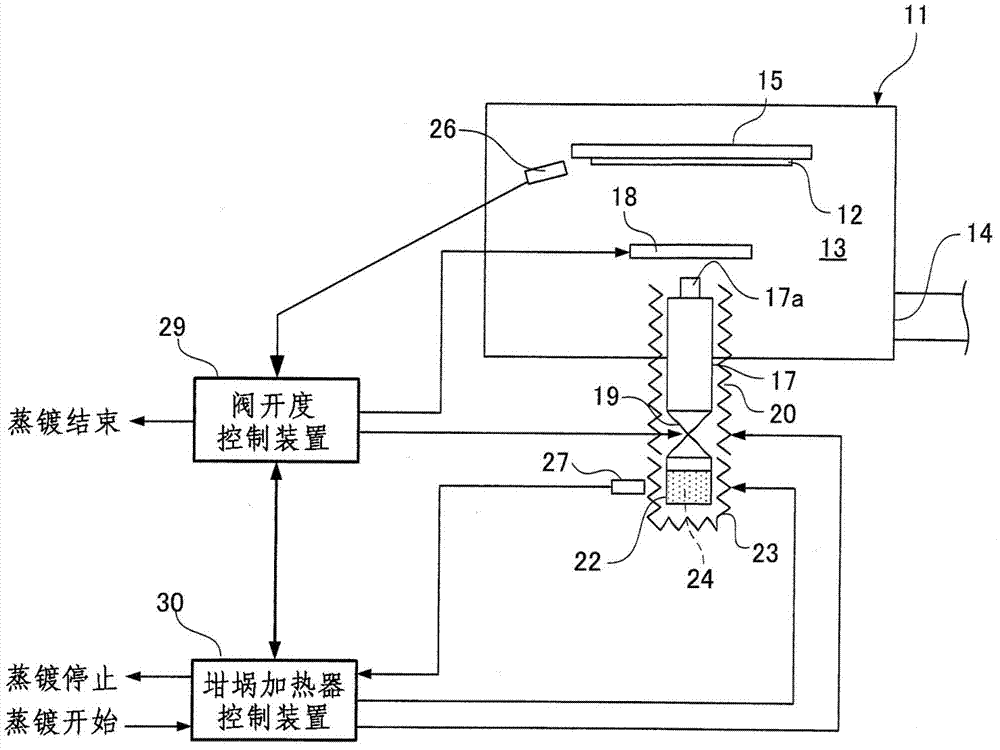

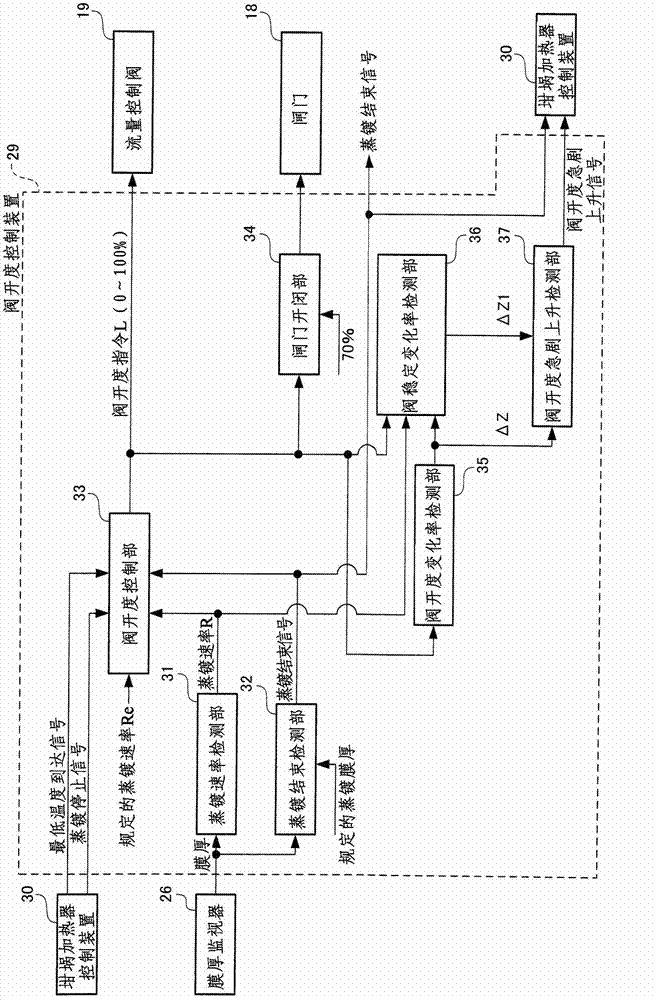

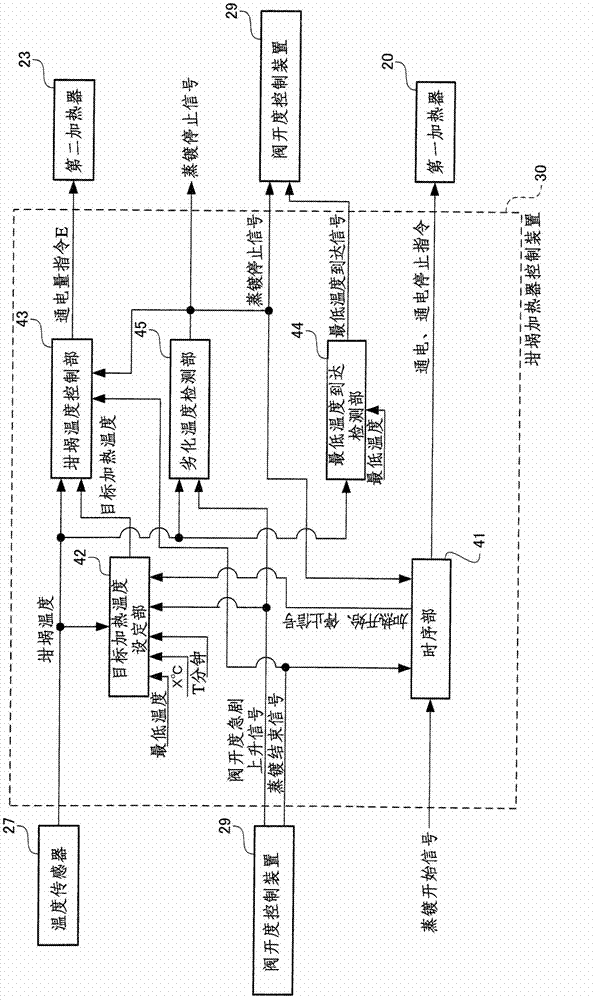

[0019] figure 1 is a structural diagram of an embodiment of the vapor deposition apparatus of the present invention. Such as figure 1 As shown, a vapor deposition chamber 13 is provided in a vacuum chamber (vacuum tank / vapor deposition container) 11, and in the vapor deposition chamber 13, a glass substrate (an example of a vapor deposition member) 12 is deposited in a vacuum atmosphere. Evaporation particles (evaporated evaporation materials such as organic EL materials) are deposited on the surface (lower surface). The vacuum chamber 11 is formed with a vacuum port 14 through which the vacuum chamber is formed into a vacuum atmosphere by a vacuum unit (not shown). The upper part of the vacuum chamber 11 is provided with a workpiece holder 15 that holds the glass substrate 12 . The illustrated vapor deposition device is an upward vapor deposition type (upward deposition) vapor deposition device, and vaporized particles are deposited from below toward the lower surface (dep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com