Floor slab waterproof protective layer construction method

A construction method and technology of cement board, applied in the direction of protective devices, infrastructure engineering, construction, etc., can solve the problems that do not involve the construction method of cement board waterproof facade protection layer, etc., and achieve simple structure, convenient and firm installation, and low construction cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

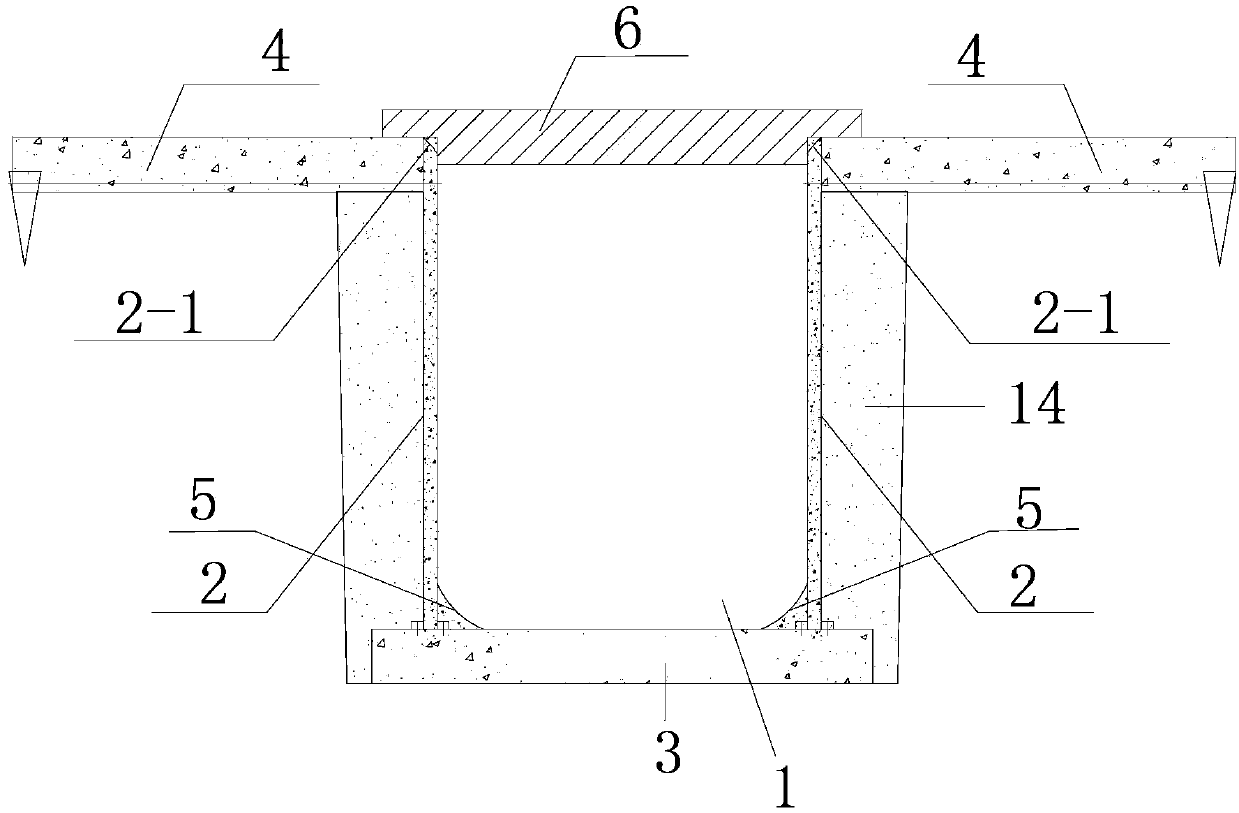

Image

Examples

Embodiment 1

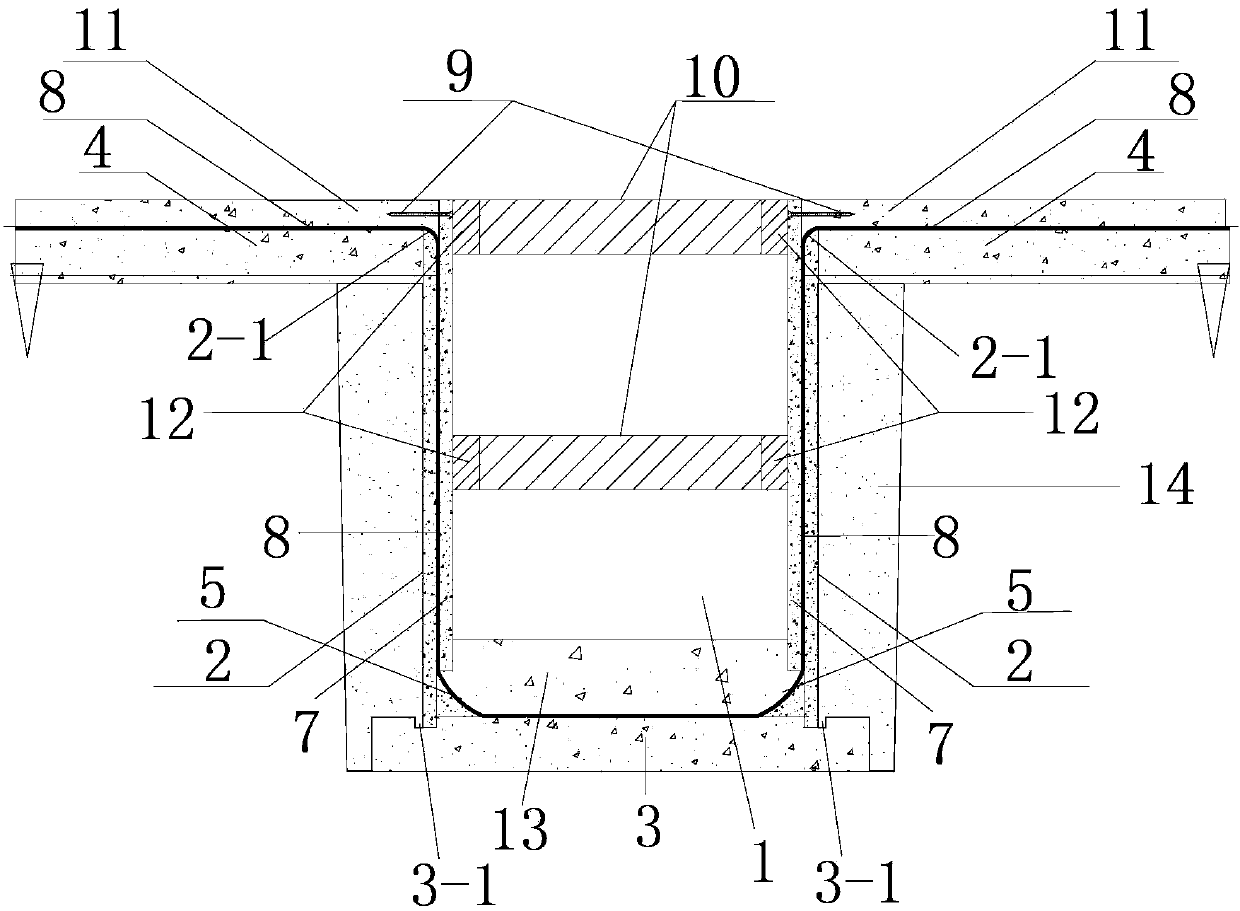

[0024] First carry out the construction of the foundation beam structure. In the construction of the foundation beam structure, grooves 3-1 are arranged on both sides of the foundation beam cushion 3, and the bottom of the cement board formwork 2 is inserted in the groove 3-1 and the bottom side of the cement board formwork The top of the wall is on the inner edge of the groove to control the positioning of the bottom of the cement board form. The construction steps of the groove are as follows: before the initial setting of the concrete of the foundation beam cushion 3, the wooden strips are pressed, so that the elevation of the upper surface of the wooden strips is consistent with the concrete elevation of the foundation beam cushion 3, and the release agent is applied on the wooden strips for removal. . After the initial setting of the concrete on the cushion of the foundation beam, lift out the reserved wooden strips, clean up the sawdust, and form the groove 3-1.

[0025...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com