Spring friction brake one-way coupling damping belt wheel

A technology of friction brake and pulley, applied in one-way clutches, belts/chains/gears, clutches, etc., can solve the problems of easy breakage, complicated manufacturing process, and low service life, and achieve reliable transmission, simple structure, and long service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

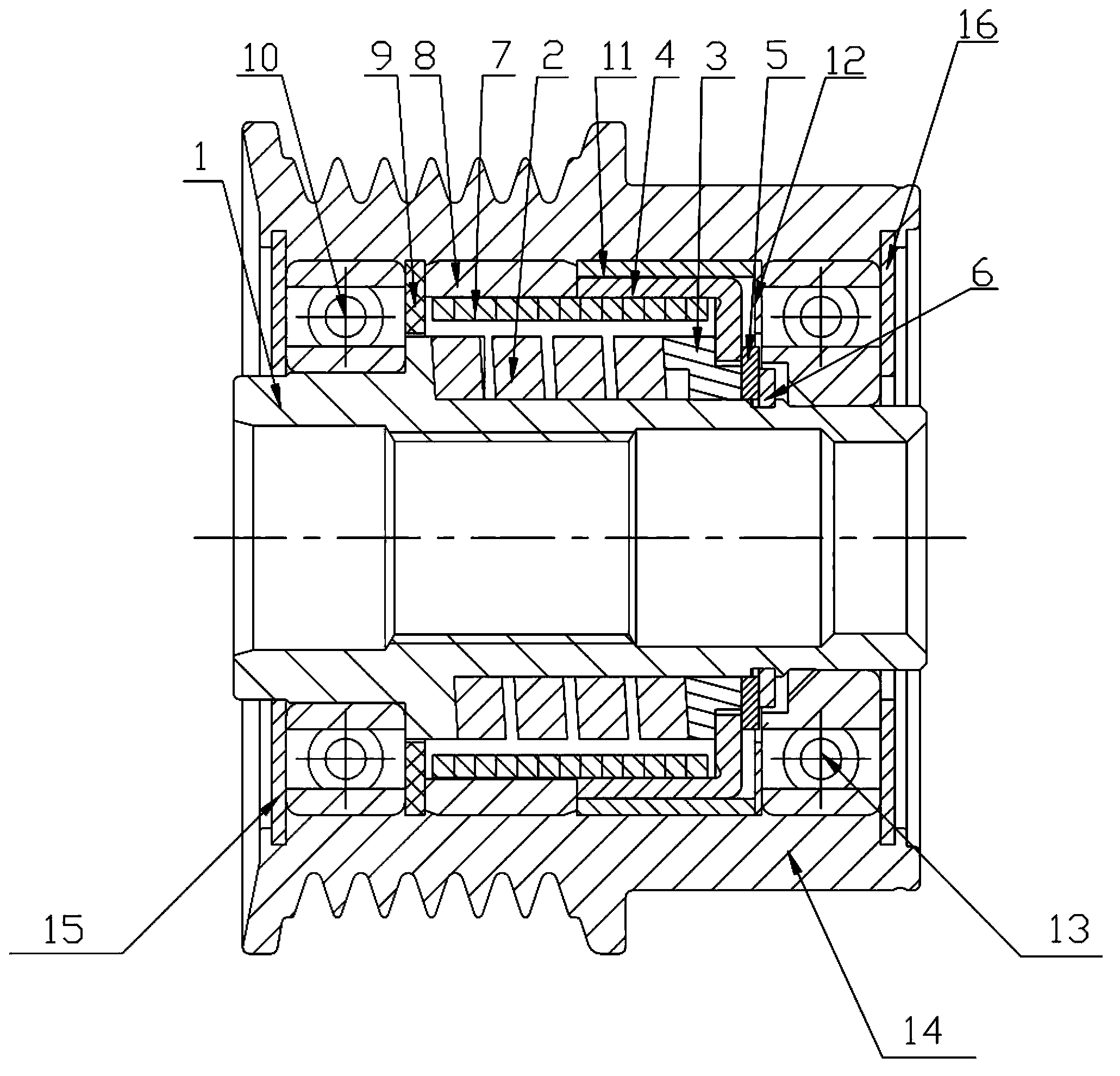

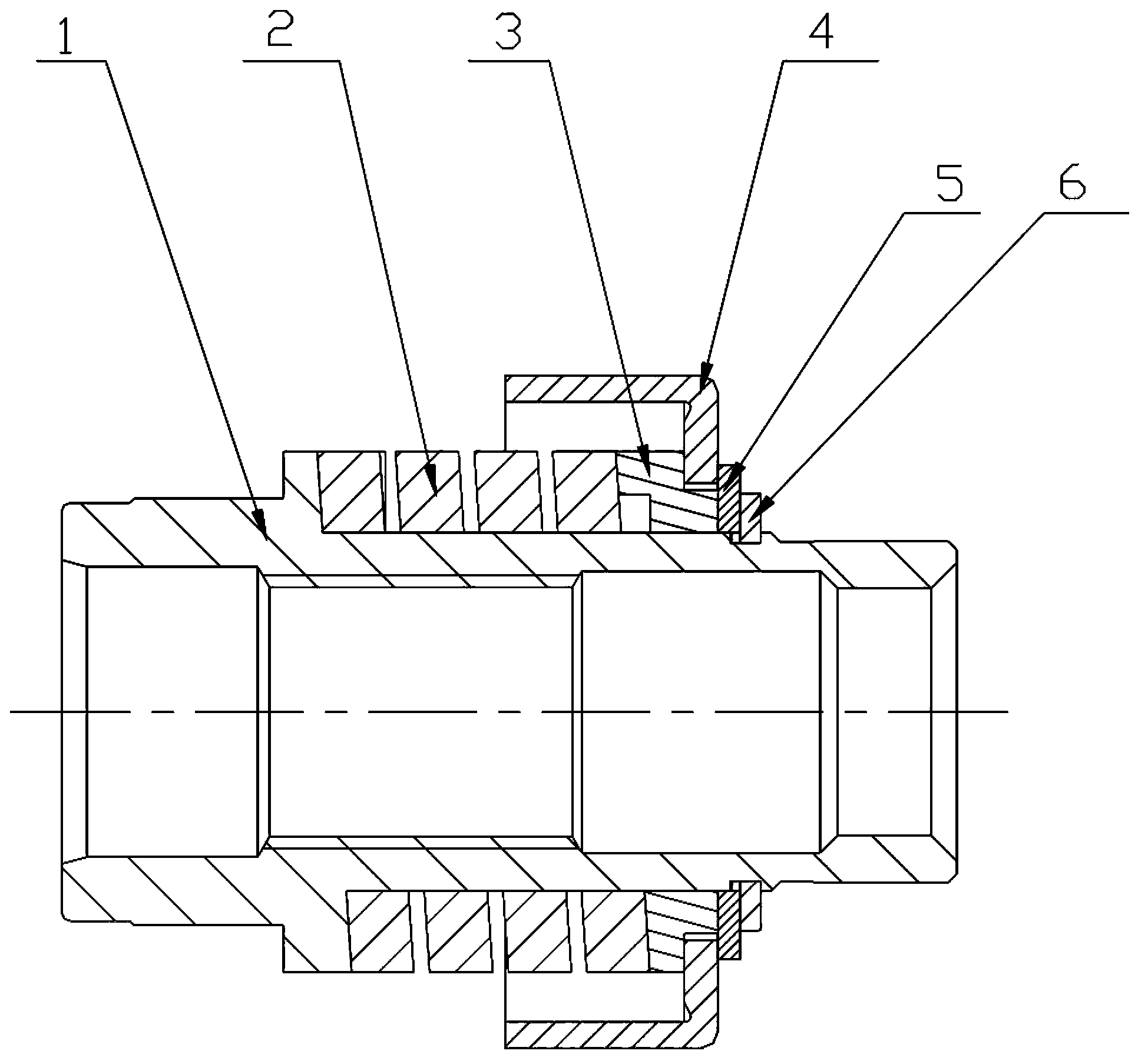

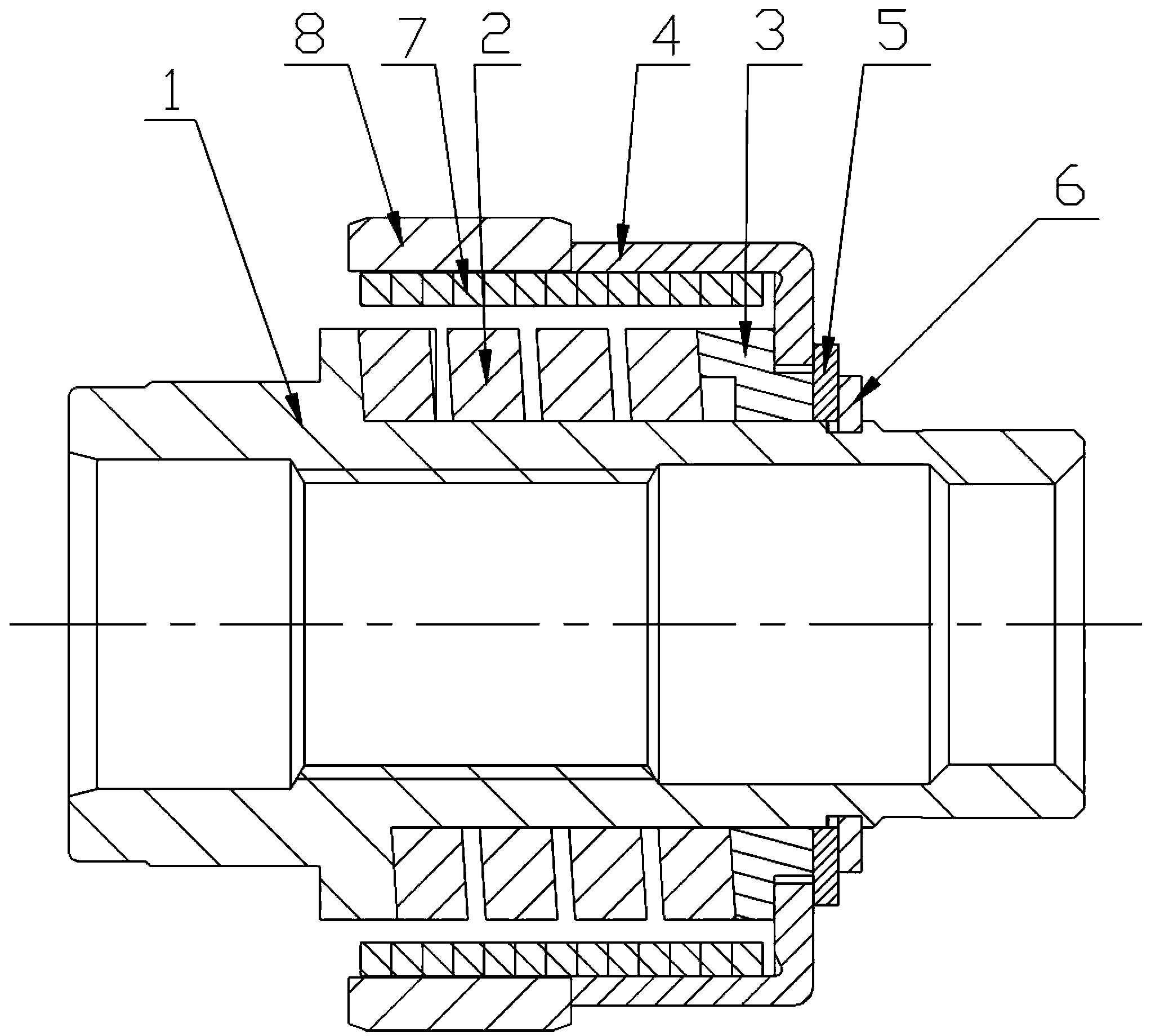

[0036] Such as Figure 1-19 As shown, the one-way coupling damping pulley of the spring friction brake in this embodiment includes a threaded mandrel 1, a damping spring 2, a damping washer 3, a friction sliding ring 4, a washer 5, a square circlip 6, a friction spring 7, Friction stop ring 8, front retaining ring 9, front ball bearing 10, positioning sleeve 11, back retaining ring 12, rear ball bearing 13, belt wheel hub 14, front dustproof gasket 15, rear dustproof gasket 16.

[0037] The inner hole of belt wheel hub 14 is equipped with a group of shock-absorbing spring mechanism. The shock-absorbing spring mechanism includes threaded mandrel 1, shock-absorbing spring 2, shock-absorbing washer 3, friction movable sleeve 4, washer 5, square retaining spring 6, threaded mandrel 1 One end of the outer diameter 1-1 forms a convex ring 1-6 with a helical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com