Housing type pipe joint

A pipe joint and ferrule type technology, which is applied in the direction of pipe/pipe joint/pipe fitting, packing and sealing connection by fluid pressure, passing through components, etc., can solve the problems of deterioration of gasket 65, reduced sealing performance, water leakage, etc. Deterioration, workability improvement, and the effect of preventing deterioration of sealing performance or water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in detail below, but the present invention is not limited by the detailed description.

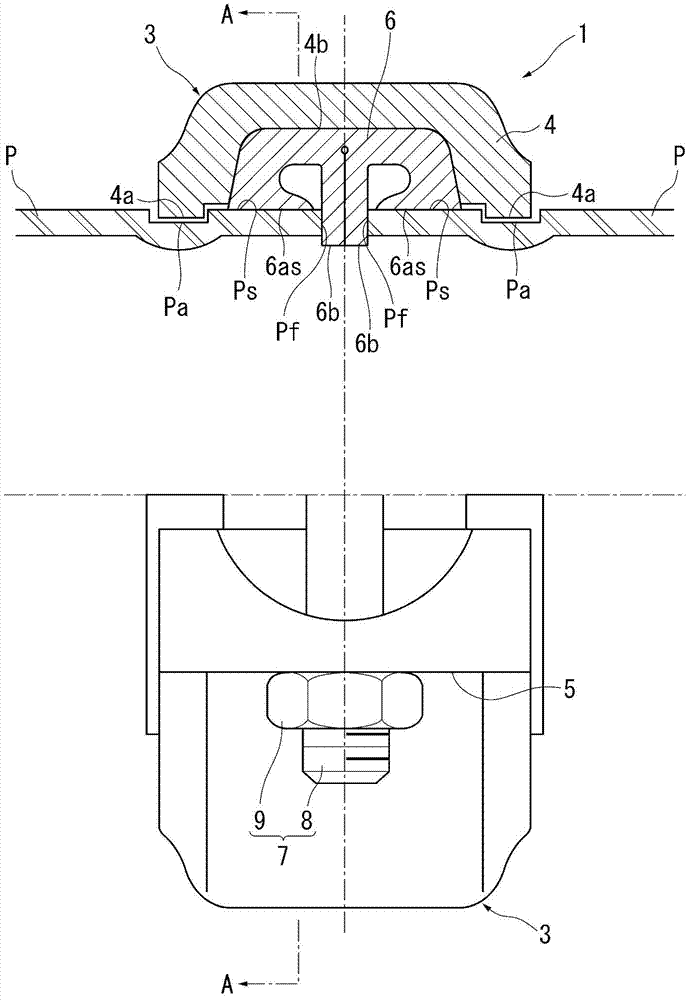

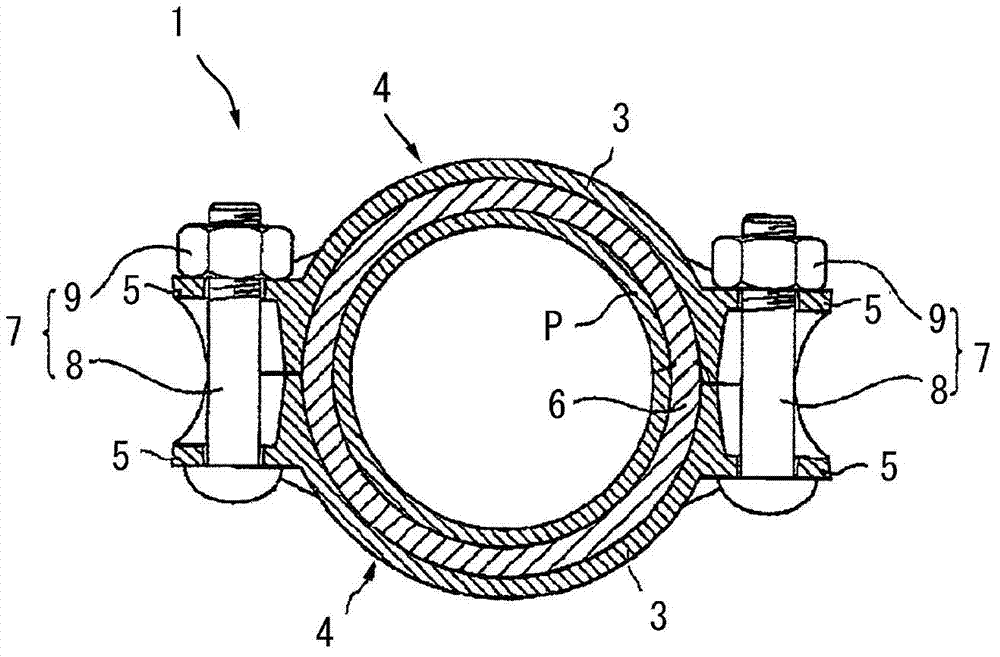

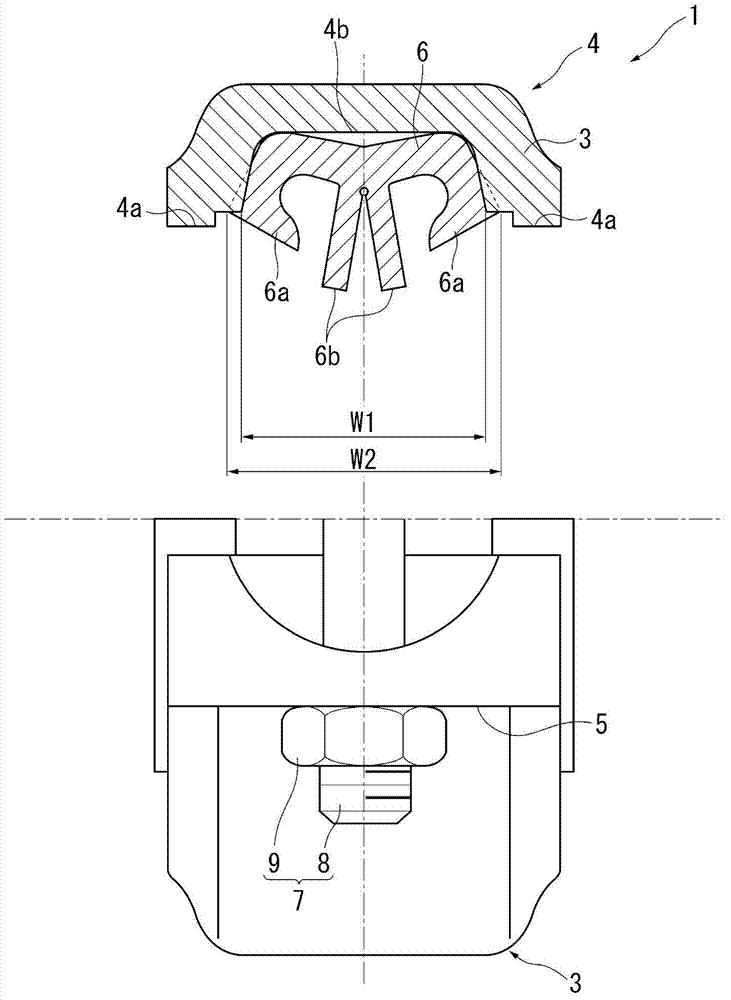

[0054] figure 1 It is a sectional view cut along a plane parallel to the axial direction of the pipe when the compression fitting 1 according to the embodiment of the present invention is attached to the pipe P, figure 2 is along figure 1 The cross-sectional view of the A-A line (obtained by cutting the plane perpendicular to the axial direction of the pipe), image 3 It is a half-sectional view obtained by cutting the ferrule-type pipe joint 1 with a plane parallel to the axial direction, Figure 4 is a half-sectional view of the gasket 6. The compression fitting 1 has a pair of sleeve bodies 4 , a washer 6 made of an annular elastic body, and a fastener 7 made of a bolt 8 and a nut 9 , and is constructed by assembling these parts.

[0055] The sleeve main body 4 has: a substantially semicircular arc-shaped portion 3; flange portions 5 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com