Flameless Combustion Compact Arrangement Horizontal Internal Combustion Fire Tube Hot Water Boiler

A flameless combustion, internal combustion fire tube technology, used in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of power difficult to exceed 14MW, harsh working environment, easy cracking of tube sheets, etc. Radiation heat transfer, good flame sufficiency and good heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

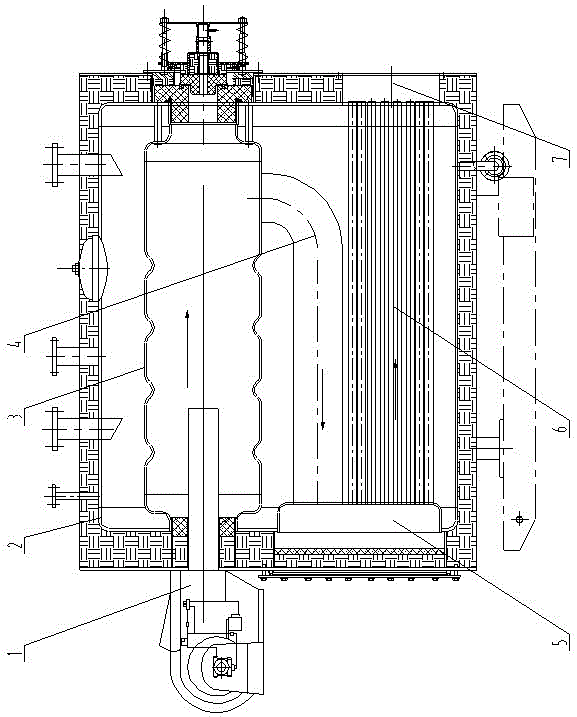

[0024] See figure 1 , figure 1 It is a schematic diagram of the overall structure of the flameless combustion compactly arranged horizontal internal combustion fire tube hot water boiler of the present invention. by figure 1 It can be seen that the flameless combustion compactly arranged horizontal internal combustion fire tube hot water boiler of the present invention is mainly composed of the burner 1, the shell 2, the one-pass furnace liner 3, the two-pass furnace liner 4, the smoke box 5, and the smoke tube convection tube bundle 6 and boiler flue gas outlet 7. The burner 1 adopts a flameless burner. The boiler shell 2 is arranged horizontally, the first-pass boiler 3, the second-pass boiler 4 and the flue pipe convection tube bundle 6 are all arranged in the boiler shell 2, the smoke box 5 is arranged in the front of the boiler shell 2, and the boiler flue gas outlet 7 It is arranged at the rear of the pot shell 2, the one-pass furnace liner 3 is placed in the upper pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com