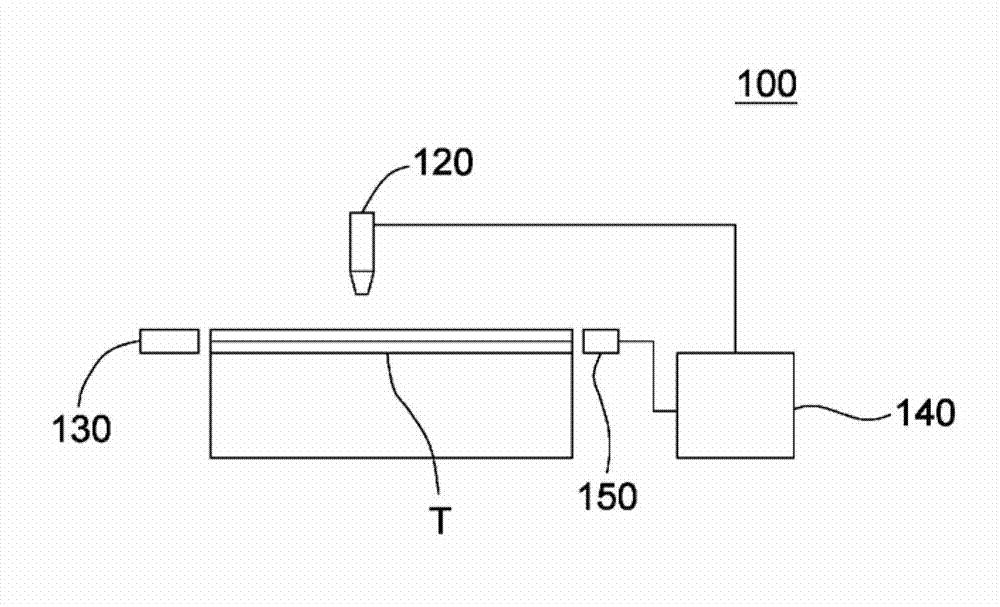

Apparatus and method for measuring thermal diffusivity

A thermal diffusivity and heat-driven technology, applied in Raman scattering, material excitation analysis, etc., can solve the problems that the spatial resolution cannot be less than 250nm, and the multilayer film cannot be measured, and achieve the effect of less requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

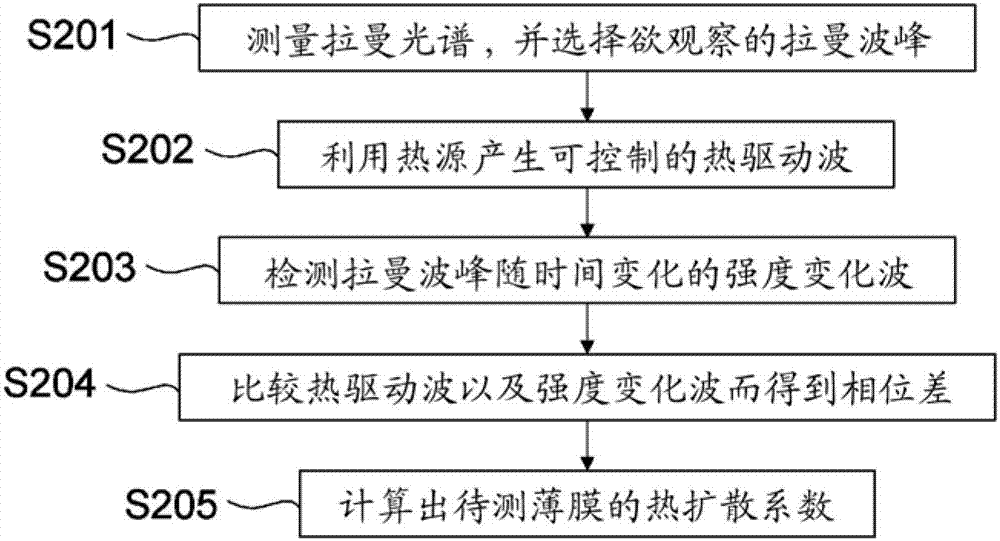

Method used

Image

Examples

experiment example 1

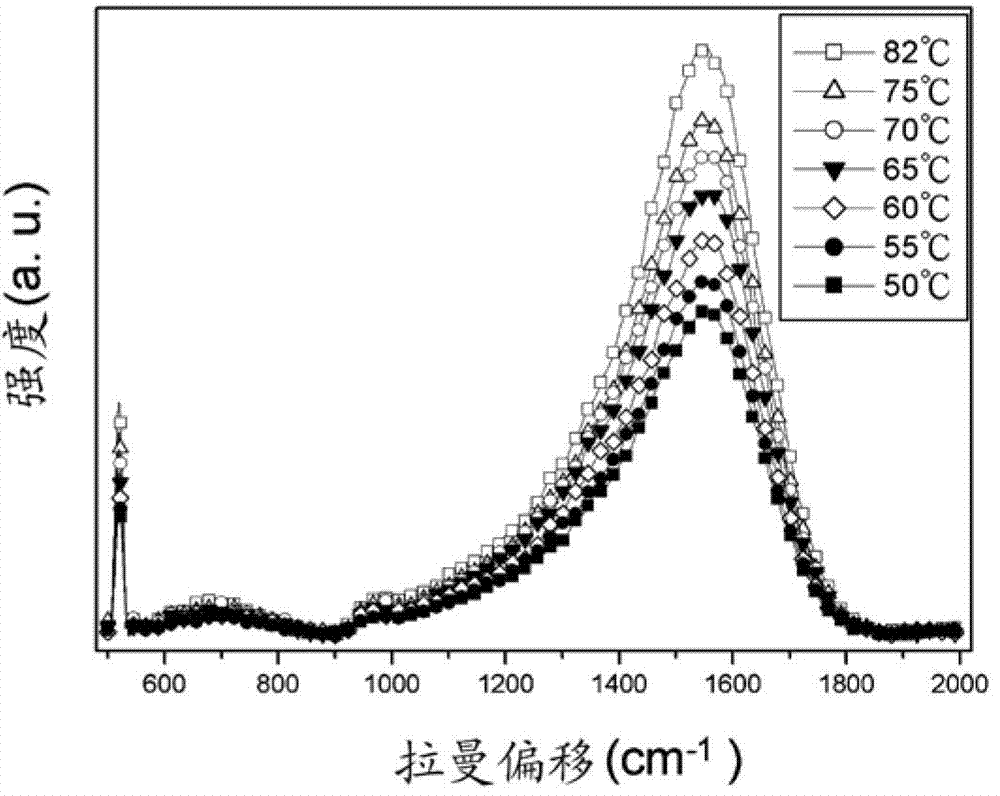

[0070] Piece to be tested (film / substrate to be tested): diamond-like carbon film (DLC, 180nm) / Si(100) substrate

[0071] Raman spectrometer: High-resolution confocal Raman Microscope (Lab RAM HR Raman Microscope, HOROBA), HeNe laser: wavelength 632.8nm, power: 20mW; magnification: objective lens 100X, aperture 0.9; resolution: focal length division 1μm.

[0072] Heating equipment: near-infrared light heating unit, the temperature control range is 50℃~82℃.

[0073] The piece to be tested is placed on the platform, and the Raman spectrum of the piece to be tested is measured by a Raman spectrometer. At this time, a wave peak at Raman shift (Raman shift) is 519.12cm -1 The location of and another peak in the Raman shift is about 1550cm -1 s position. At Raman shift (Raman shift) is 519.12cm -1 The peak at the position represents the signal of Si, and the Raman shift (Raman shift) is 1550cm -1 The position of the peak represents the DLC signal.

[0074] Next, a near-infrare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com