Method for analyzing hot pneumostatic elasticity of hypersonic aerocraft

A technology of hypersonic speed and analysis method, applied in the direction of instruments, special data processing applications, electrical digital data processing, etc., can solve the problems of low efficiency and long calculation time, achieve high efficiency, fast calculation speed, and improve the effect of calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

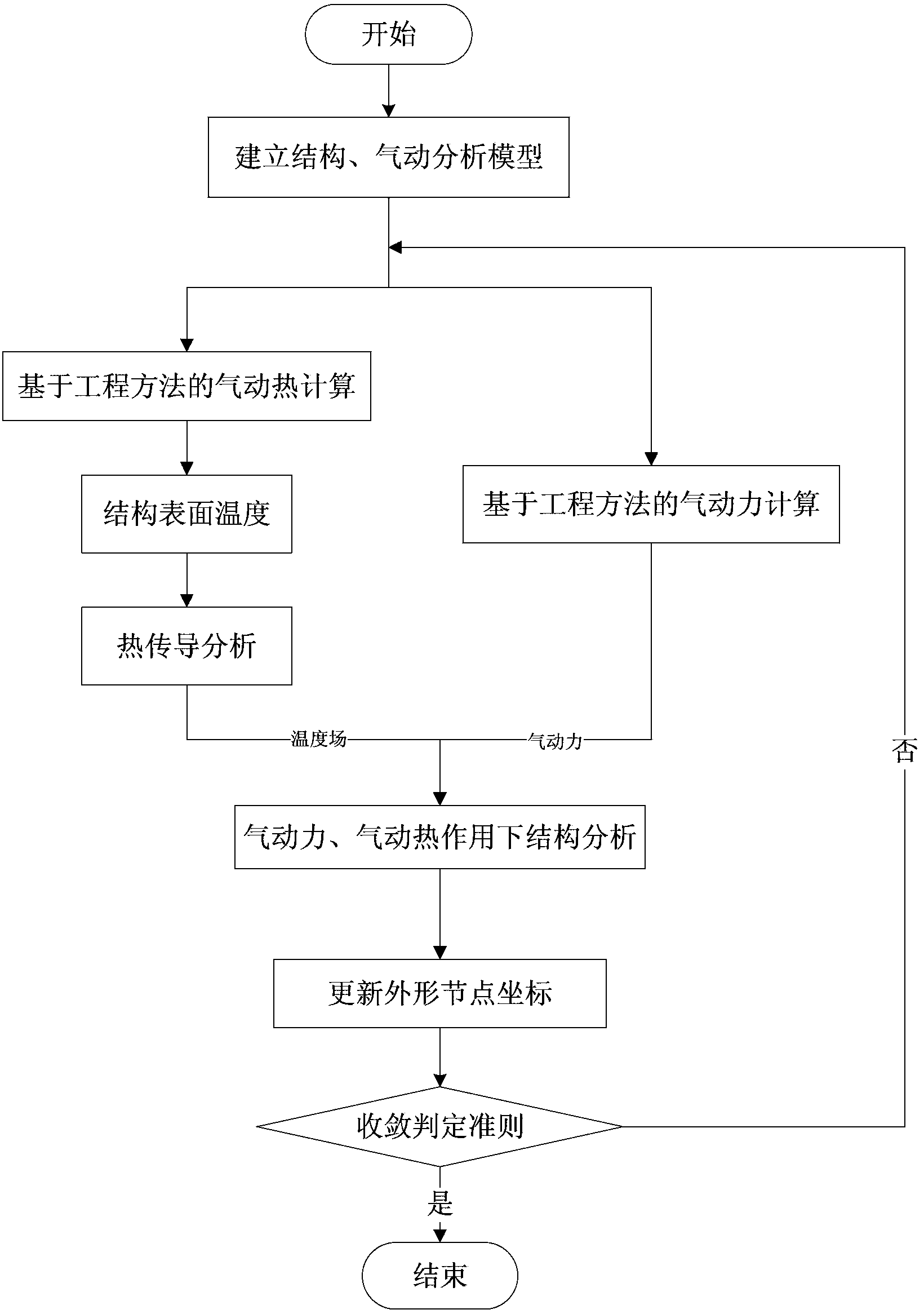

[0020] A hypersonic vehicle thermostatic aeroelastic analysis method of the present invention, the steps are as follows:

[0021] (1) According to the initial shape of the aircraft, establish the structure and aerodynamic analysis model of the hypersonic aircraft; the aerodynamic analysis model refers to the aerodynamic shape model of the hypersonic aircraft composed of triangular facets; the structural analysis model refers to the limited structure of the aircraft The element analysis model is to assign corresponding material properties to each part of the aircraft, and then divide the aircraft structure into finite element elements, such as shell elements, body elements, etc., and impose fixed support constraints at the center of gravity.

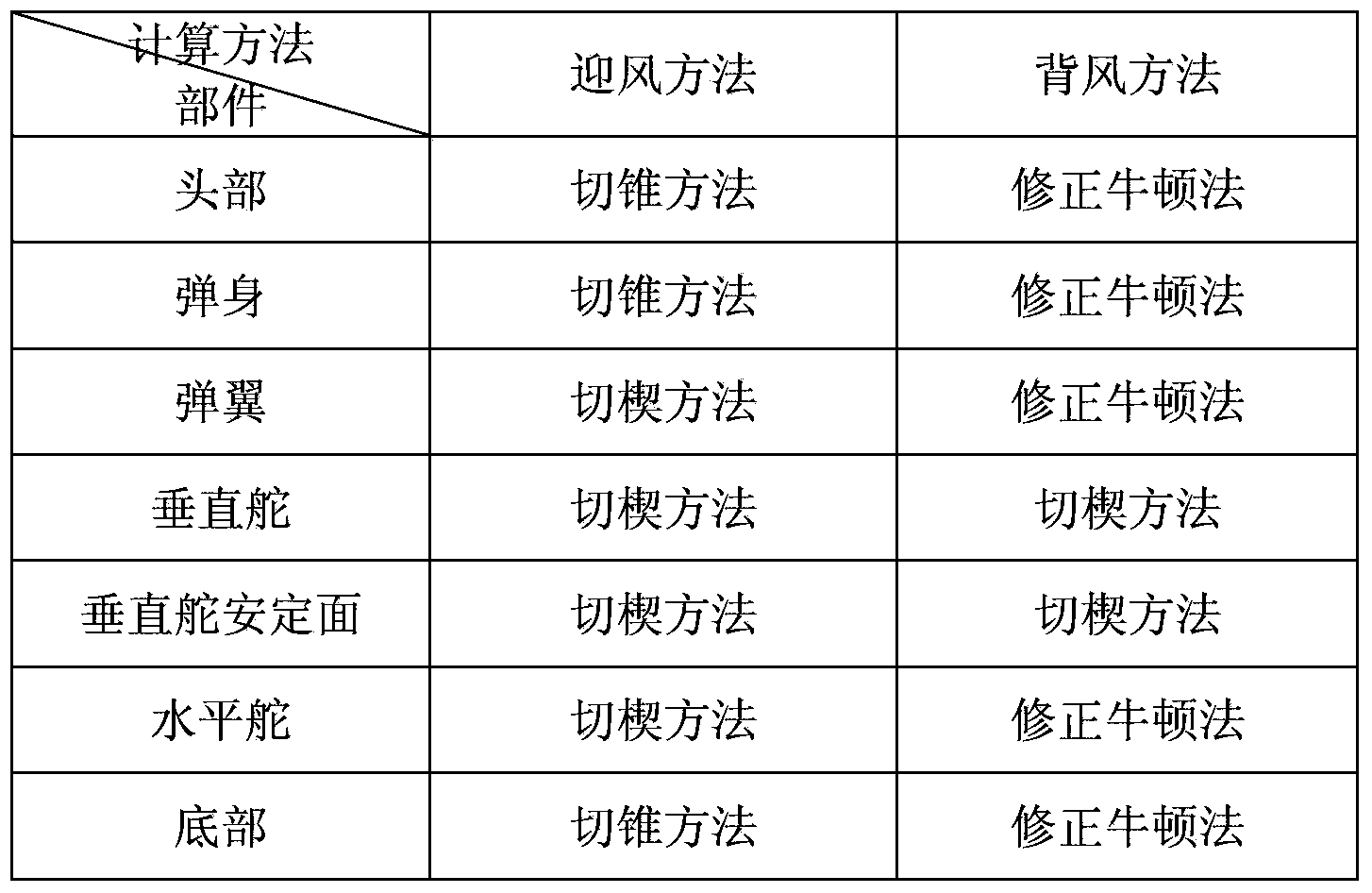

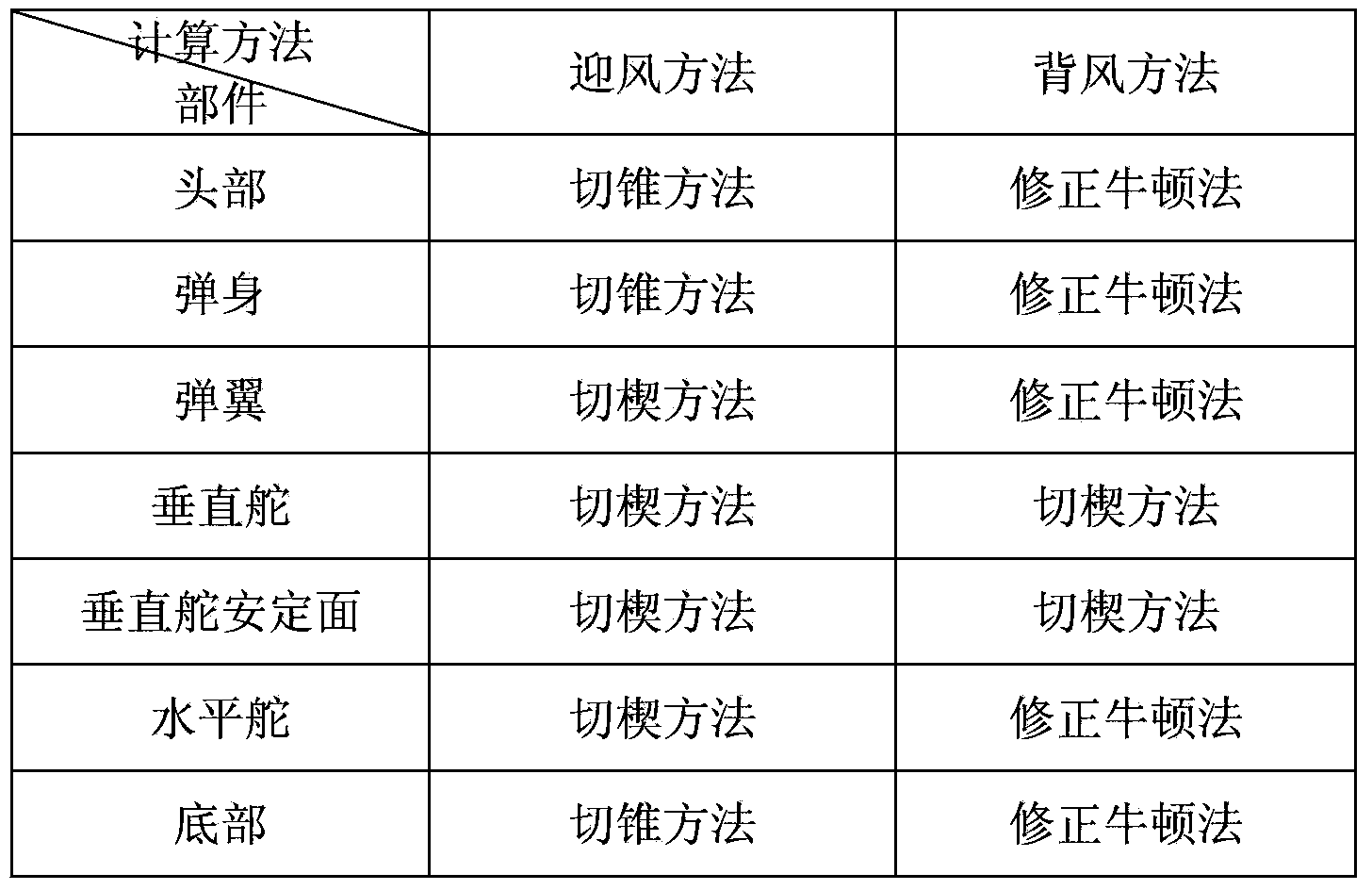

[0022] (2) Use engineering methods to calculate aerodynamic forces and aerodynamic heat for hypersonic vehicles; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com