Small-beam-spot X-ray equipment

An X-ray and beam spot technology, applied in the direction of X-ray tube electrodes, X-ray tube components, etc., can solve problems such as poor imaging quality, large X-ray beam spot area, damage, etc., to avoid unnecessary damage, high definition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

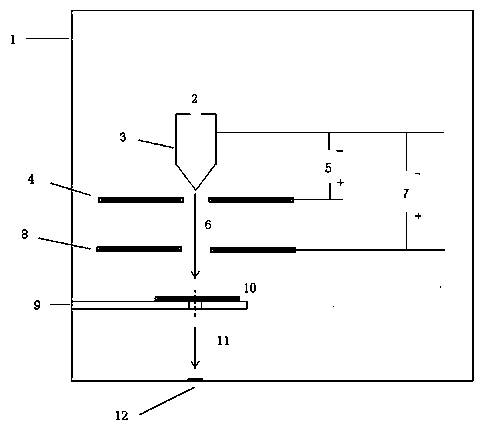

[0009] Such as figure 1 As shown, the field emission electron gun cathode device is housed in the vacuum X-ray sealing sleeve 1 . The field emission electron gun cathode device includes a field emission filament 3 connected to a flash power supply 2 . A field emission power supply 5 is connected between the field emission filament 3 and the anode 4 of the field emission power supply. The field emission filament 3 emits an electron beam 6 under the strong electric field generated by the field emission power supply 5 . The electron beam 6 moves to the anode 8 of the acceleration power supply through the acceleration power supply 7, and obtains high energy after acceleration. The high-energy electron beam irradiates on the target 10 cooled by the ring-shaped target cooling water device 9 to generate X-rays 11. Since the target 10 is relatively Thin, the generated X-rays 11 exit the X-ray tube through the beryllium window 12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com