Thin film transistor, manufacturing method thereof, array substrate and display

A technology of thin film transistors and manufacturing methods, which is applied in the direction of transistors, electric solid-state devices, semiconductor devices, etc., can solve the problems of leakage current and generation of leakage current of thin film transistors, and achieve the effect of high stability characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

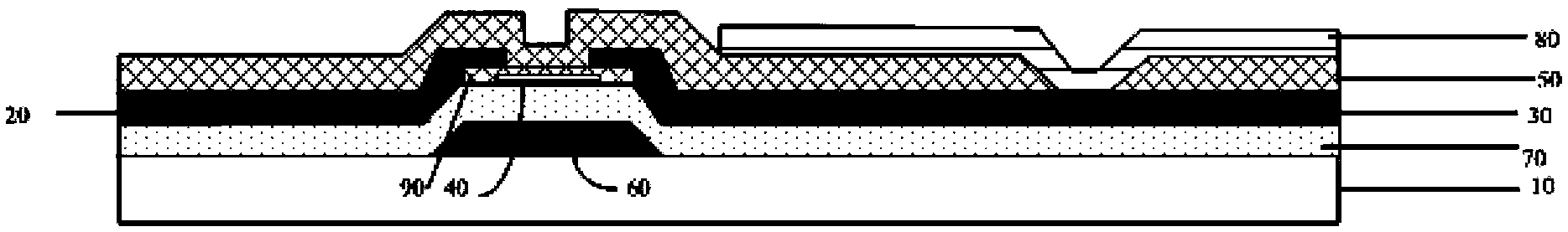

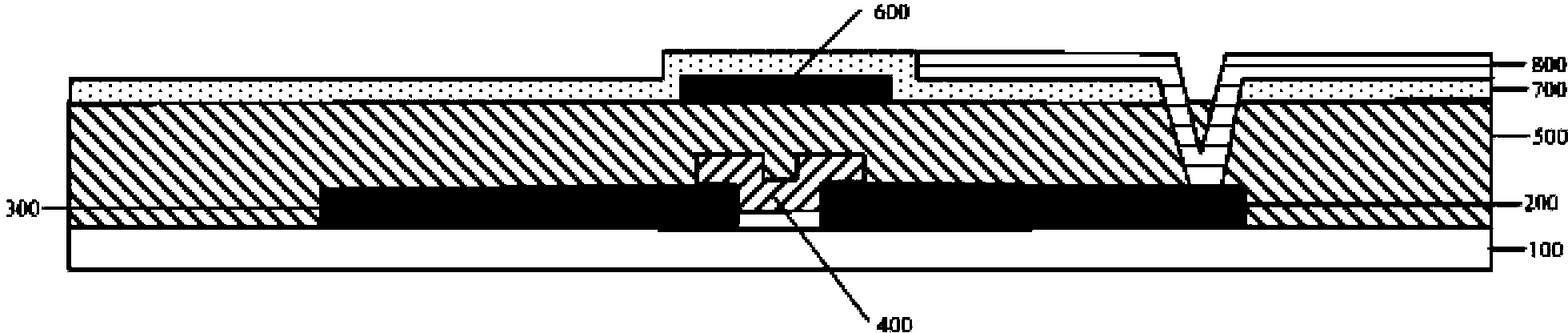

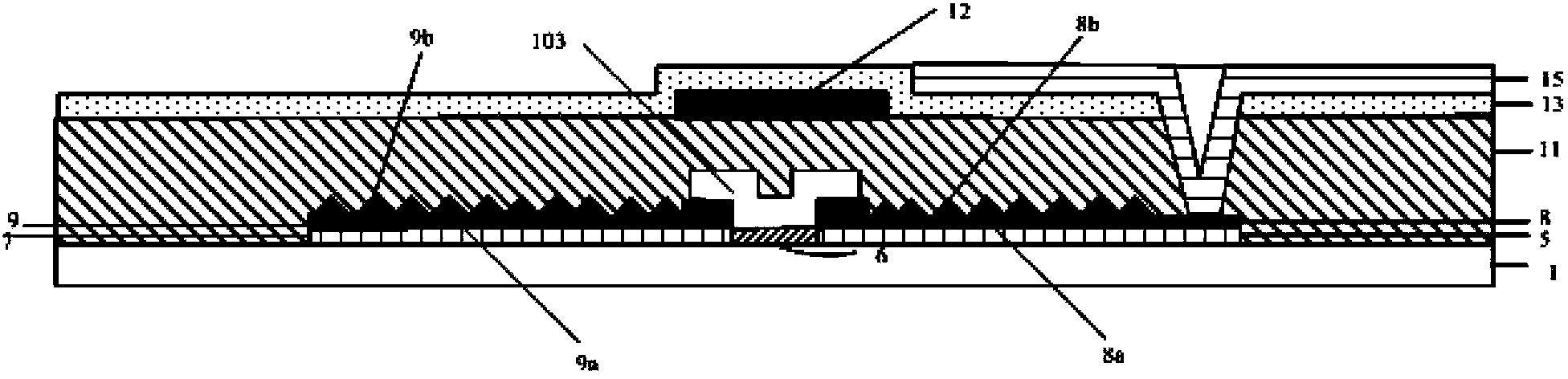

[0044] Option one, in Figure 7 On the basis of dry etching, the metal oxide IGZO semiconductor active layer without photoresist coverage area is completely etched away. With the progress of dry etching, the thickness of photoresist is also correspondingly thinned. The photoresist 41 covered on the metal oxide IGZO semiconductor active layer 102 area is thinner, and the photoresist 42 covered on the metal oxide IGZO semiconductor active layer 103 area is thicker, when the metal oxide IGZO semiconductor active layer When the photoresist covered on the 102 region is completely etched away to expose the metal oxide IGZO semiconductor active layer, when the dry etching is continued at this time, the metal oxide IGZO metal oxide IGZO semiconductor active layer 102 region The role of the semiconductor active layer and Figure 7 The jagged photoresist 41 has the same effect, and the metal oxide IGZO semiconductor active layer in the metal oxide IGZO semiconductor active layer 102 re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com