Automatic positioning method for mounting and packaging radiating cover

An automatic positioning and heat-dissipating cover technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as inaccurate alignment, and achieve the effects of avoiding poor stability, stable bonding process, and improved pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

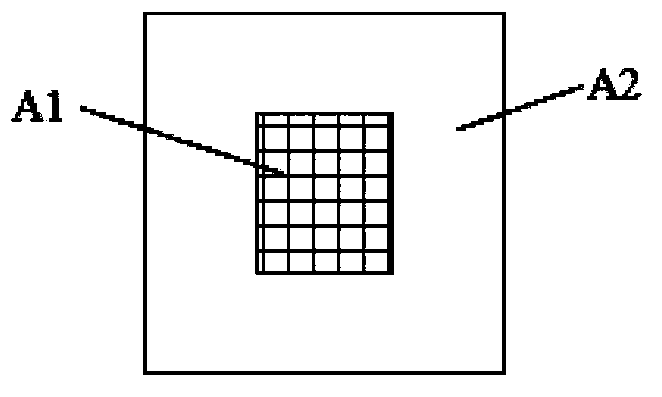

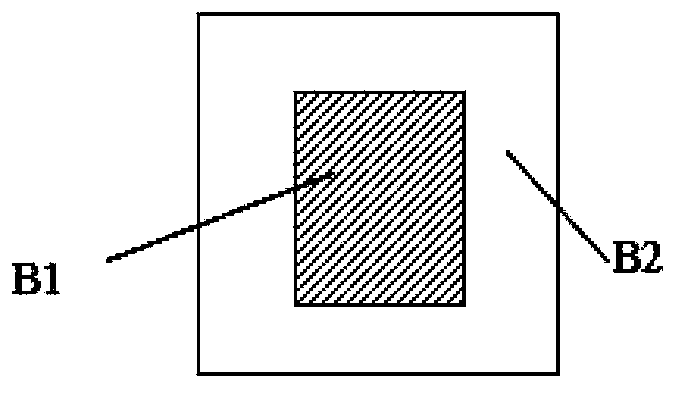

Image

Examples

Embodiment Construction

[0029] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

[0030] The invention makes the process of installing the heat dissipation cover controllable through the independent mold design, completes the combination of the heat dissipation cover and the substrate on which the silicon chip has been installed, and makes it a packaged integral device.

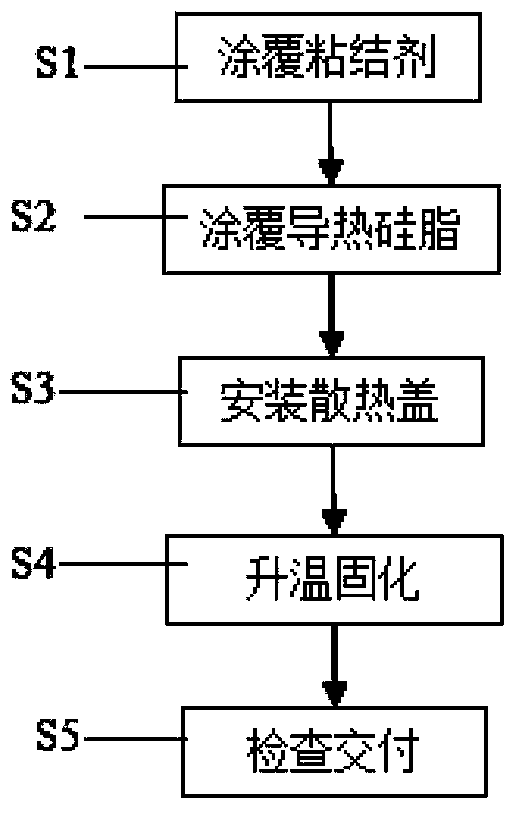

[0031] Figure 4 A flow chart of an automatic positioning method for installing a package heat dissipation cover according to a preferred embodiment of the present invention is schematically shown.

[0032] Such as Figure 4 As shown, the automatic positioning method for installing the package heat dissipation cover according to the preferred embodiment of the present invention includes:

[0033] The first step S01: manufacturing the cooling cover position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com