Optimized interconnected strip connection method used for photovoltaic assembly

A photovoltaic module and connection method technology, applied in the direction of electrical components, welding equipment, semiconductor devices, etc., can solve the problems of increased board layout, reduced production efficiency, cost waste, etc., and achieve the goals of simplifying operations, improving production efficiency, and saving production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

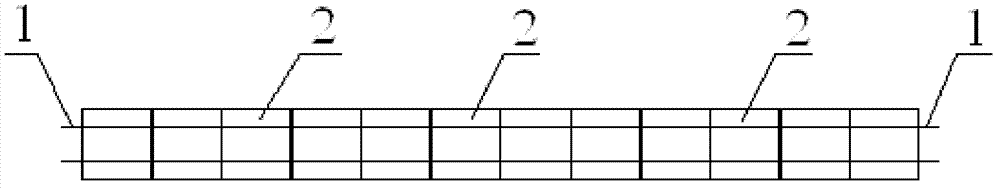

[0015] A method for optimizing the connection of interconnection strips for photovoltaic modules. The method adds two interconnection strips 1 of shorter length for the connection of both ends of the battery string, and specifically includes the following steps:

[0016] (1) When welding a single battery piece 2, according to the number of battery strings, use a shorter interconnection bar 1 to weld on the first battery piece;

[0017] (2) The rest of the cells are welded sequentially with interconnection strips of conventional length, and the short interconnection strip 1 is welded on the back of the last cell;

[0018] (3) During the lamination operation, the interconnection strips at both ends of the battery string that exceed the cells are welded to the bus bar and cut to obtain a connected photovoltaic module. When the interconnection strip exceeds the edge of the bus bar by 1-2mm, it will It needs to be cropped and can be used directly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com