Sedimentation type liquid-liquid separator

A liquid-liquid separator and sedimentation technology, applied in the direction of liquid separation, immiscible liquid separation, separation methods, etc., can solve the problem of excessive liquid separation function, it is difficult to fully improve the separation efficiency of inclined passages or settling components, and cannot perform Solve problems such as liquid separation function, achieve the effect of increasing flow rate and promoting uniform mixing ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

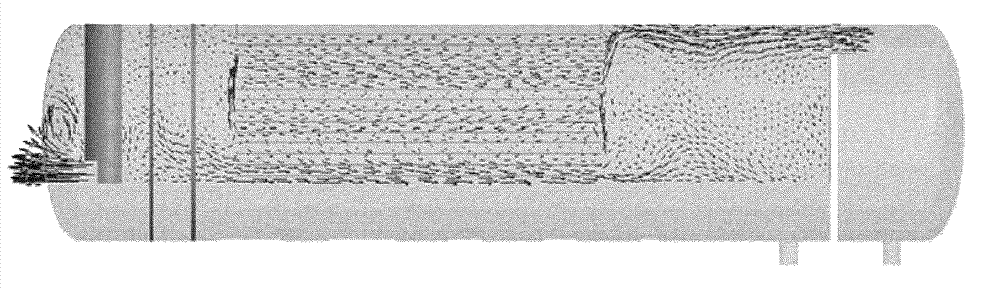

[0126] Next, when a liquid mixture in which two or more types of liquids having different specific gravity are mixed with each other is separated using a sedimentation type liquid-liquid separator, the flow of the liquid mixture in the liquid passage and the volume of water in the liquid mixture are performed rate numerical simulation.

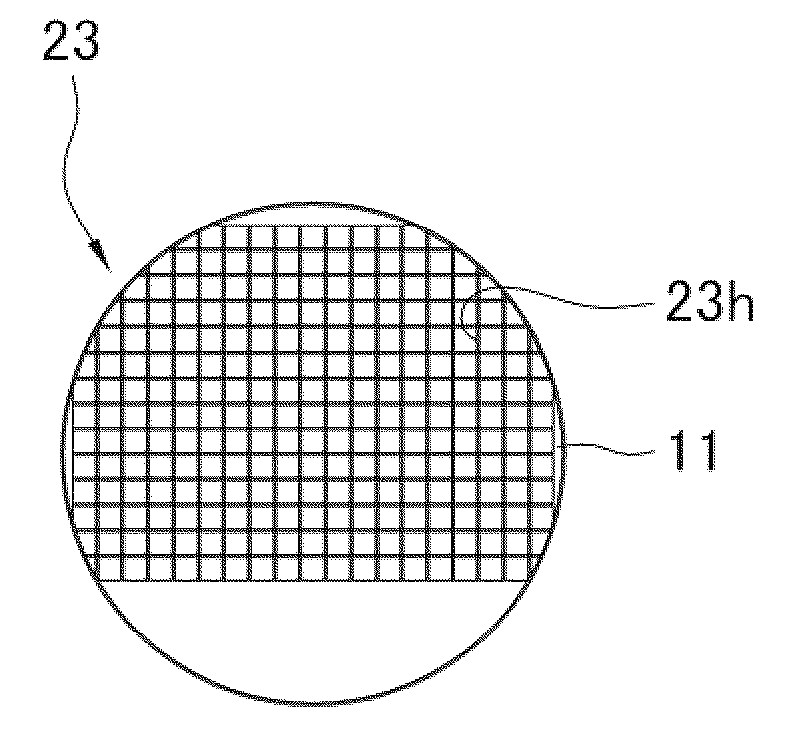

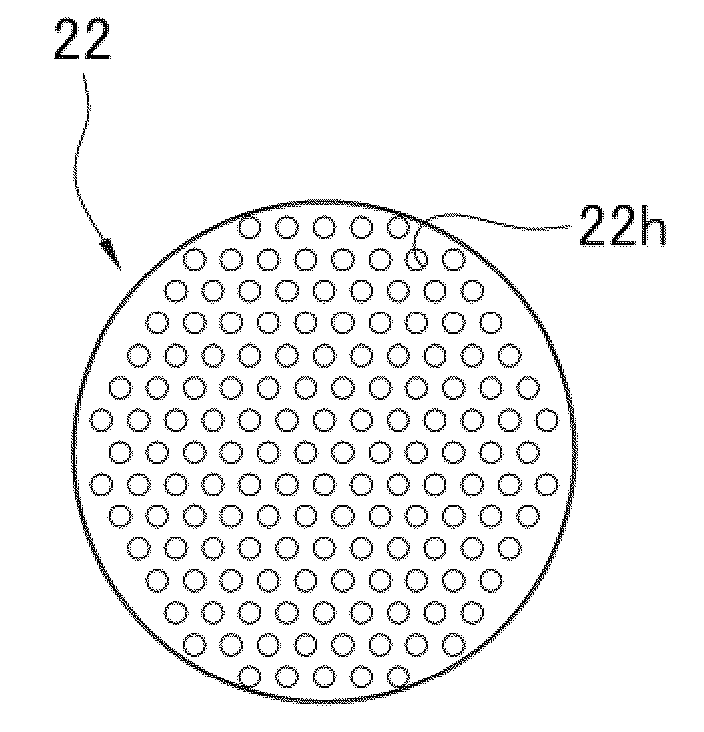

[0127] to have figure 1 Numerical simulations were performed on the sedimentation type liquid-liquid separator of the present invention (example) and the sedimentation type liquid-liquid separator (comparative example) having the structure of FIG. 4 .

[0128] Calculations are performed according to ANSYS CFX. The calculation conditions are as follows.

[0129] (1) Liquid mixture

[0130] Liquid mixture: including oil (density 900 kg / m 3 and a viscosity of 1.5 cP) and water (with a density of 970 kg / m 3 and a liquid mixture with a viscosity of 0.4 cP).

[0131] Flow rate of liquid mixture: 70 m 3 / h

[0132] Flow ratio: water: oil = 1:2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com