Pump-turbine system

A turbine and equipment technology, applied in mechanical equipment, pumps, pump devices, etc., can solve problems such as difficulty in power adjustment of pump turbine equipment, and achieve good power adjustment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

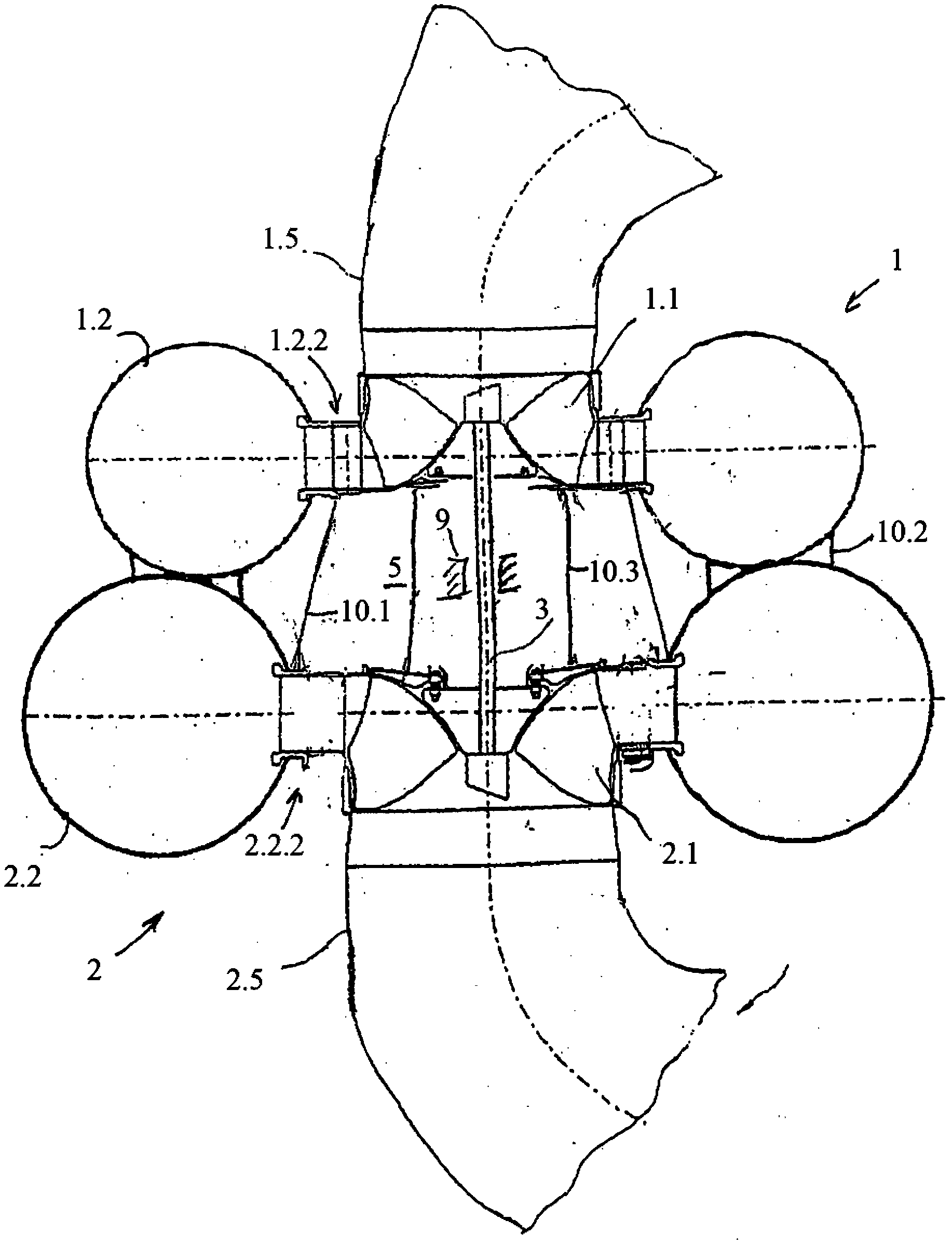

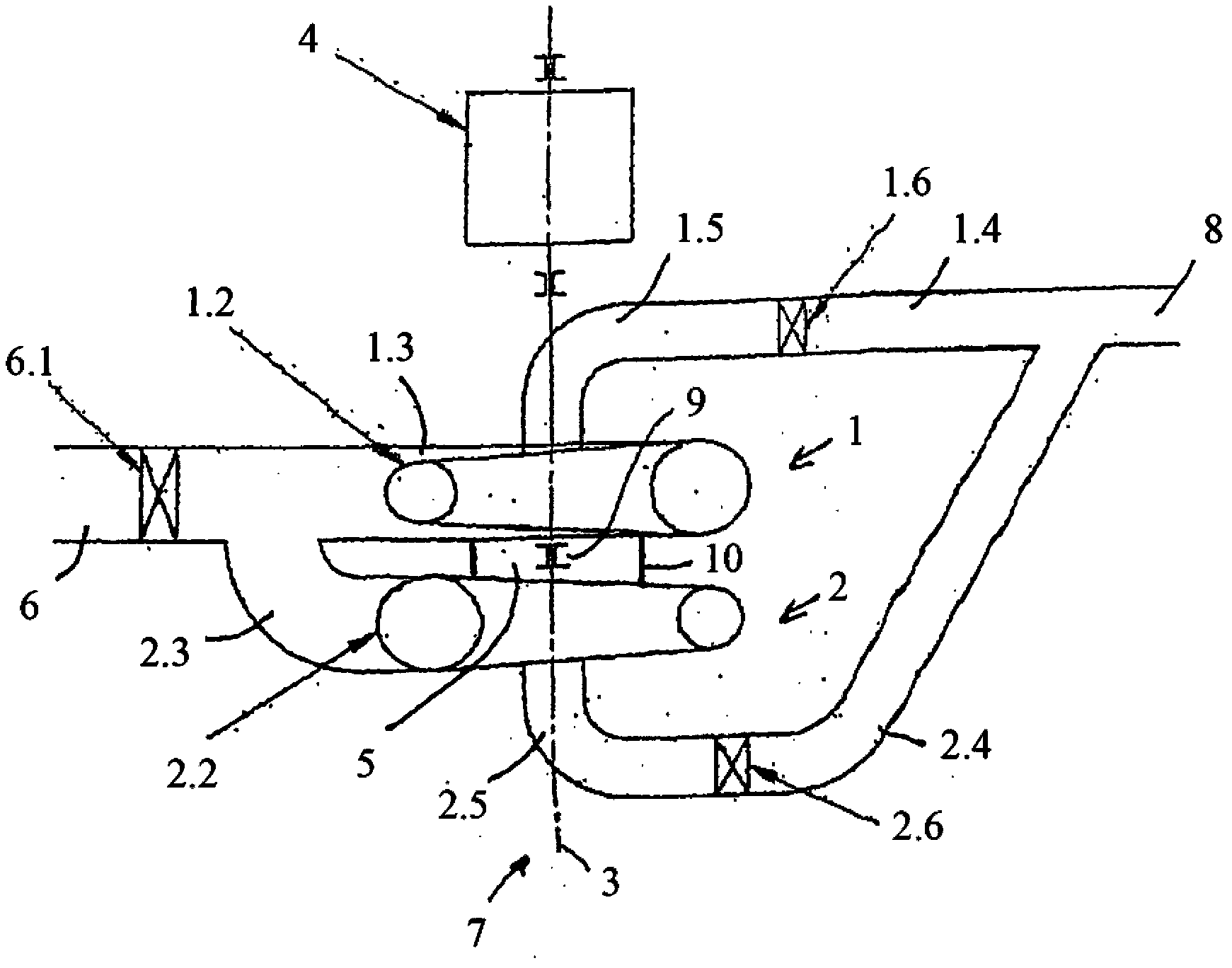

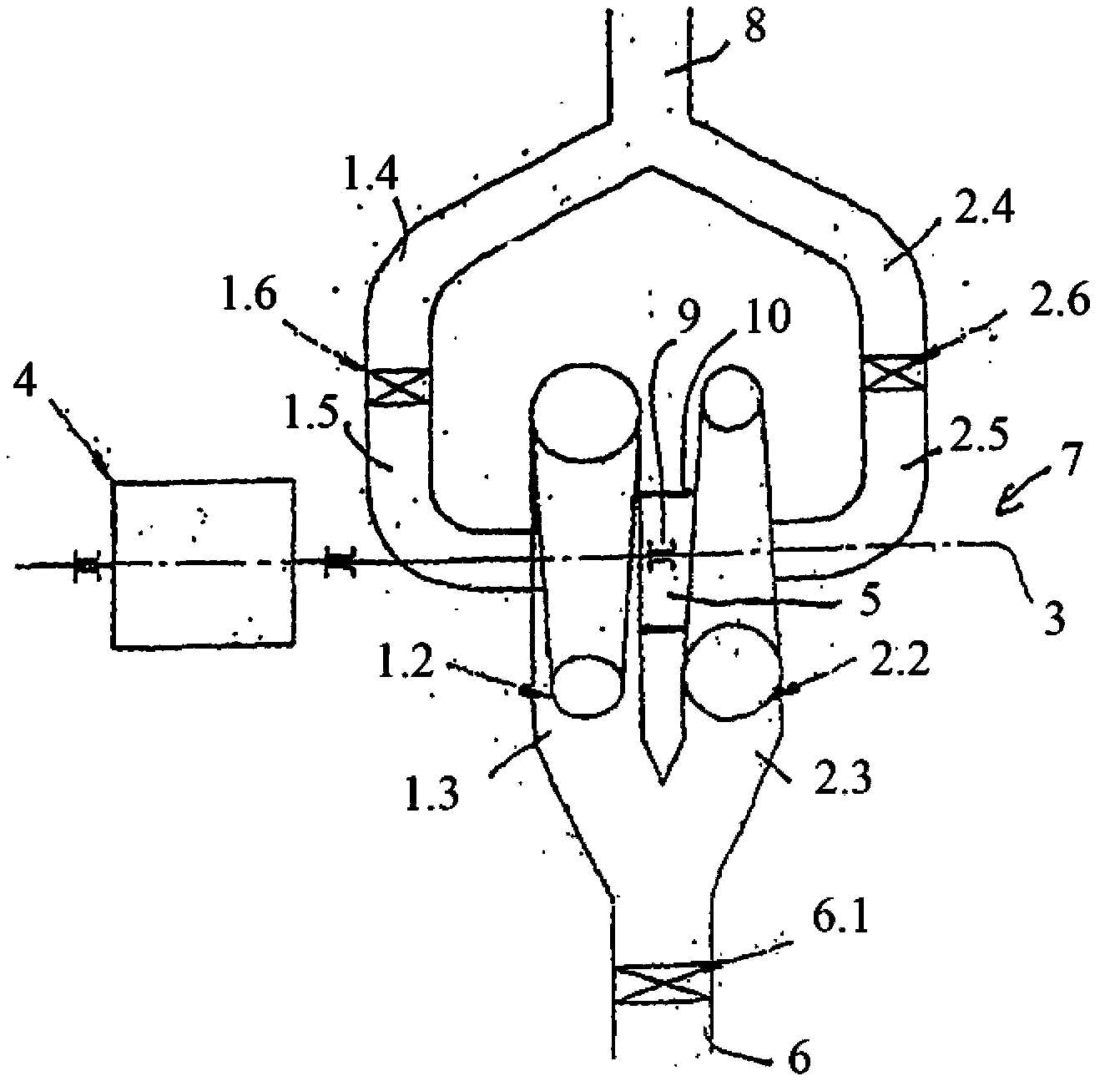

[0025] exist figure 1 The pump turbine arrangement shown in is constructed as follows: The turbine 1 comprises a turbine impeller 1.1 comprising a plurality of blades. The turbine wheel 1.1 is designed to be rotatably connected to the shaft 3 and its axis of rotation 7 is rotatably mounted. The turbine wheel 1.1 is surrounded by a turbine spiral housing 1.2. Furthermore, the edges of the guide vanes adjoin upstream of the turbine wheel 1.1.

[0026] The turbine 1 has a turbine suction line 1.5. It is connected after the vanes and comprises an inlet diffuser with an elbow connected thereto and a pipe connected thereto, the flow cross-section of which can widen in the flow direction of the water.

[0027] Currently, turbine 1 and pump 2 face each other directly. The latter means that the two hydraulic machines are arranged axially adjacent to each other without an electric machine generator between them. The pump 2 is located below the turbine 1 here.

[0028] The pump 2 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com