Pneumatic tire

A technology of pneumatic tires and tires, applied in tire parts, tire tread/tread pattern, transportation and packaging, etc., can solve the problems of inability to obtain tire performance, insufficient rigidity of the tread portion, unevenness, etc., and achieve excellent manufacturing. Dynamic/driving performance and cornering performance, good drainage performance, and the effect of high driving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

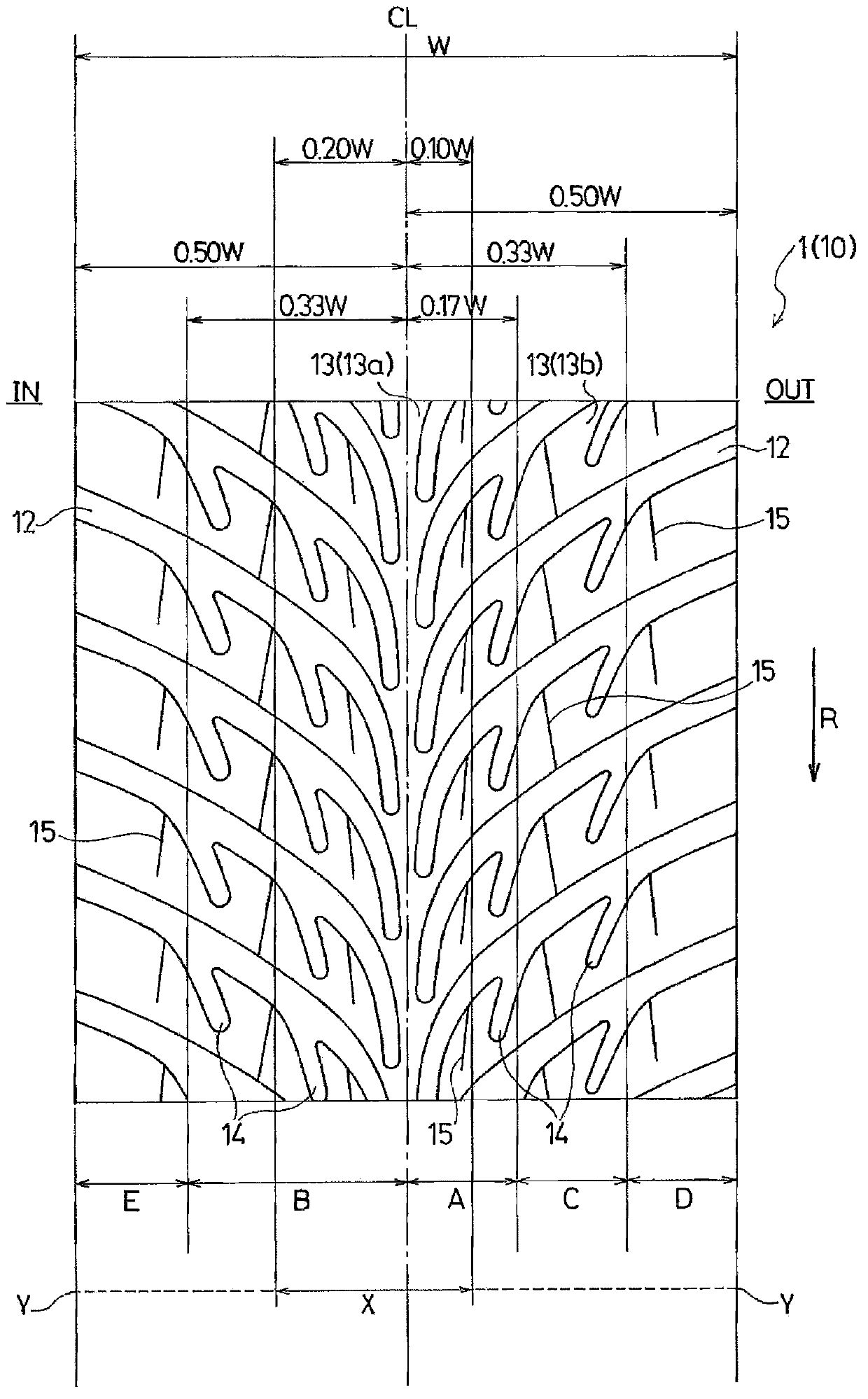

[0057] In addition, the interval W2 and the interval W3 are displayed in proportion to the interval W1. Additionally, the front wheels measure 330 / 710R18 and the rear wheels measure 330 / 710R17.

[0058] In addition, in Conventional Example 1, the tread portion is divided into 6 equal parts, and the groove area ratios of these regions are set. When corresponding to the regions A to E, the region B will be divided into two equal parts. Therefore, the groove area ratio R in Tables 1 to 3 is B In the column of , two values are described in the order of "equator line side / tire width direction outside". In addition, regarding the groove area ratio R of Conventional Example 1 A with R B difference (|R A -R B |), as the groove area ratio R B It is the value which adopts the area closer to the equator line side.

[0059] These 21 types of pneumatic tires were evaluated for uneven wear resistance, water surface skid resistance, wet handling stability, and heating performance by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com