Anti-skid rubber glove

A non-slip rubber and glove technology, applied in the field of rubber products, can solve the problems of uneven surface thickness of finished gloves, reduce the protective effect of gloves, and the surface of the rubber film is broken, etc., and achieve simple structure, improve anti-slip effect, and ensure anti-slip effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

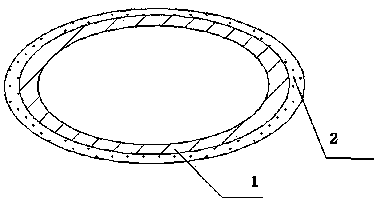

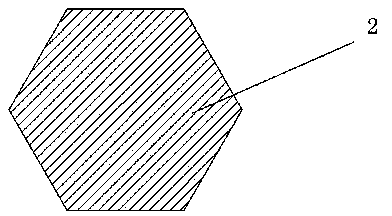

[0015] As shown in the figure, in order to solve the above technical problems, a non-slip rubber glove of the present invention includes a glove body 1, and anti-slip particles 2 are arranged on the outer surface of the glove body 1, and the cross-sectional shape of the anti-slip particles 2 is hexagonal , during processing, the glove body is dipped in the emulsion containing anti-slip particles, and then molded by drying and other processes. For the convenience of use, the anti-slip particles 2 are preferably rubber particles. The anti-slip particles are distributed on the outer surface of the glove body, and can be distributed as a whole, or only on the fingers and palms of the glove body 1 .

[0016] What is described in the above specification is only the specific implementation of the present invention, and the illustration does not limit the essence of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com