Automobile tire chain

A technology of automobile tires and anti-skid chains, which is applied in anti-skid devices, tire parts, vehicle parts, etc., can solve problems such as heavy weight, increased tire wear, and broken anti-skid chains, and achieves easy storage, reduced friction, and avoids breakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

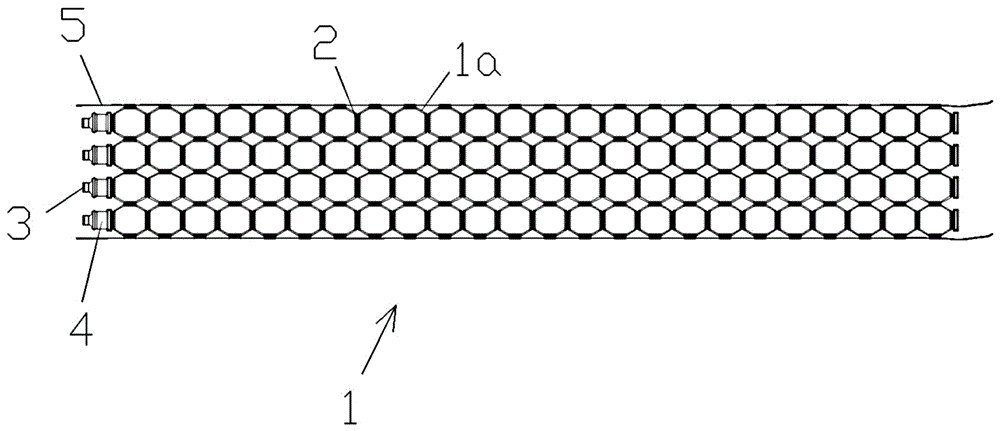

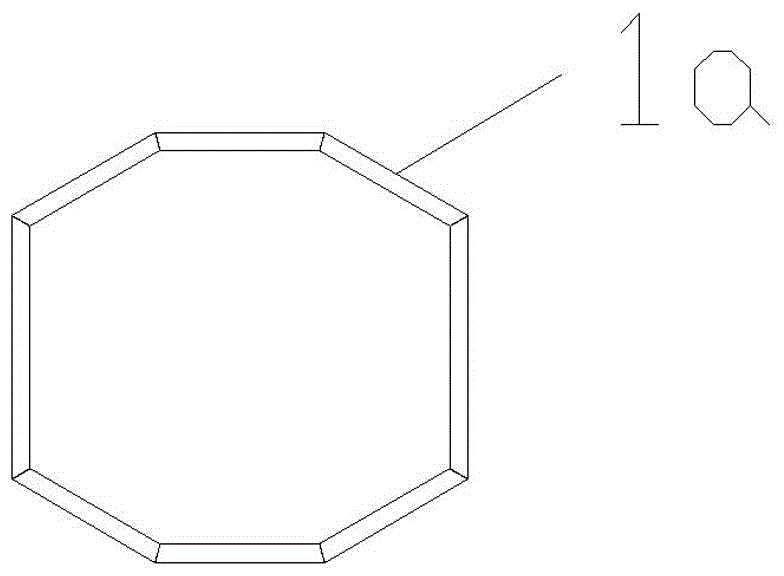

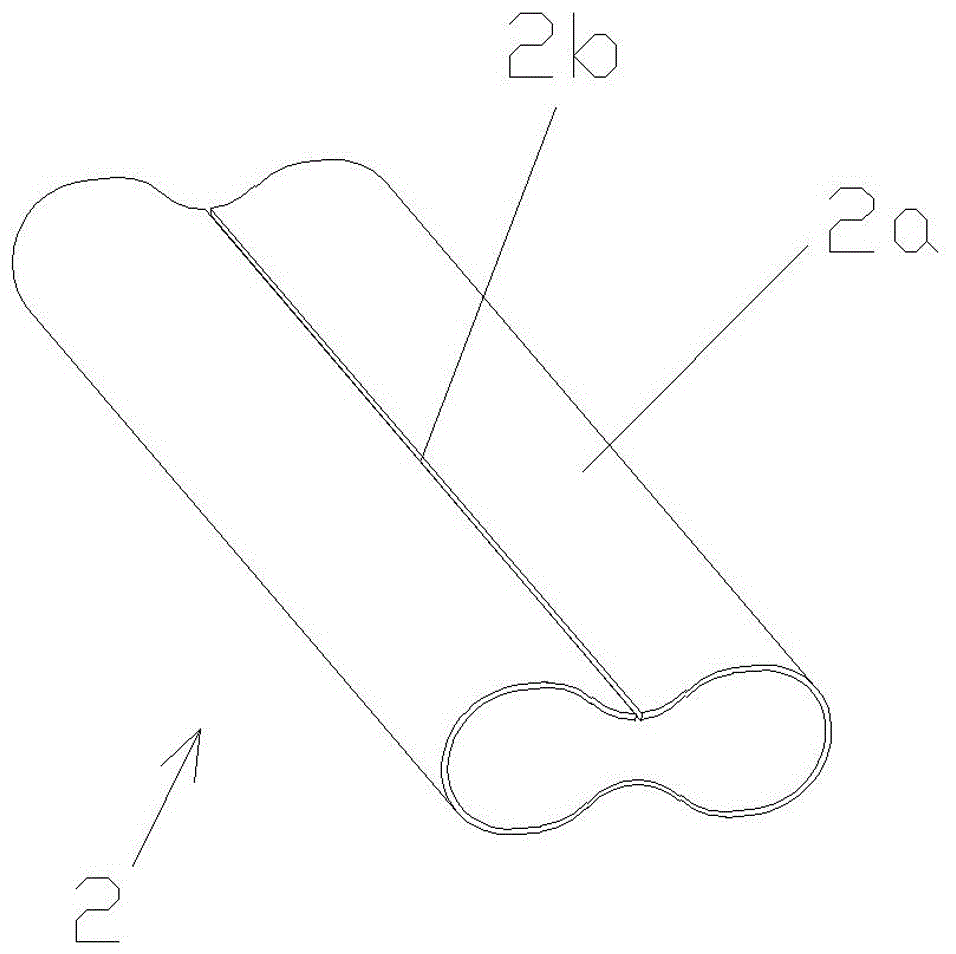

[0016] combine figure 1 and figure 2 As shown, the present invention provides an automobile tire anti-skid chain 1, comprising a group of chain link units 1a spliced with each other, the chain link unit 1a is an octagonal steel ring, the steel ring can be wound with a light steel wire rope, and each chain link unit is respectively The rectangular chains are sequentially spliced along the horizontal and vertical directions; image 3 and Figure 4 As shown, the coupling piece 2 is two chain link sleeves 2a arranged side by side, and the two chain link sleeves 2a are respectively formed to cooperate with the two sides of the connected chain link unit 1a; in order to further reduce the weight, two The chain link sleeves are connected, and an open groove 2b is provided at the junction of the two chain link sleeves to facilitate the snapping in of the side of the chain link unit 1a; the length of the rectangular chain is adapted to the circumference of the tire , the width o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com