Electromagnetic hoisting system for wide and thick steel plate

A kind of steel plate, electromagnetic technology, applied in the direction of load hanging components, transportation and packaging, etc., to achieve the effect of accurate lifting operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

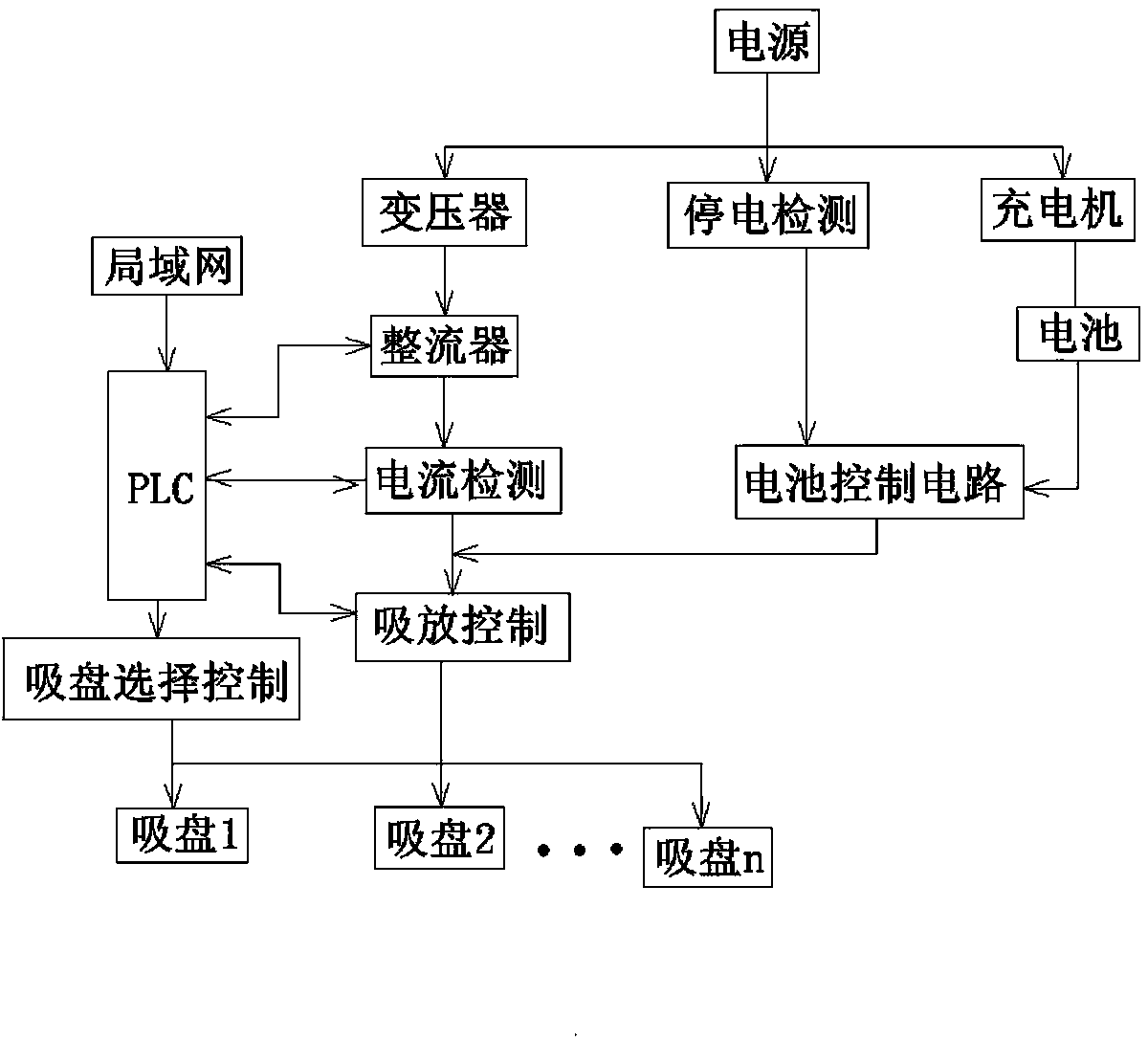

[0011] As shown in the figure, the present invention includes a main control unit, a transformer, a rectifier, and a contactor. The rectifier and the contactor are respectively connected to the main control unit; the rectifier is connected to the power supply through the transformer.

[0012] The main control unit adopts PLC.

[0013] The invention also includes a battery, which is connected to the contactor through the battery control circuit.

[0014] Such as figure 1 Shown. The main electronic control circuit is composed of a PLC main control unit, a transformer, a controllable rectifier module and a contactor. The PLC main control unit realizes the electromagnet adjustment by controlling the controllable rectifier module, and the power on and off selection of each suction cup is realized by the PLC control contactor. These main circuits constitute the magnetic modulation and magnetic retention control panel and the automatic charging screen. Together with the maintenance-fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com