Multifunctional combined lightweight concrete curtain wall and constructing method thereof

A light-weight concrete and multi-functional combination technology, applied to walls, building components, buildings, etc., can solve the problems of environmental impact of materials, walls cannot be transported, and construction costs increase, so as to achieve good decorative effects, reduce construction costs, The effect of reducing noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

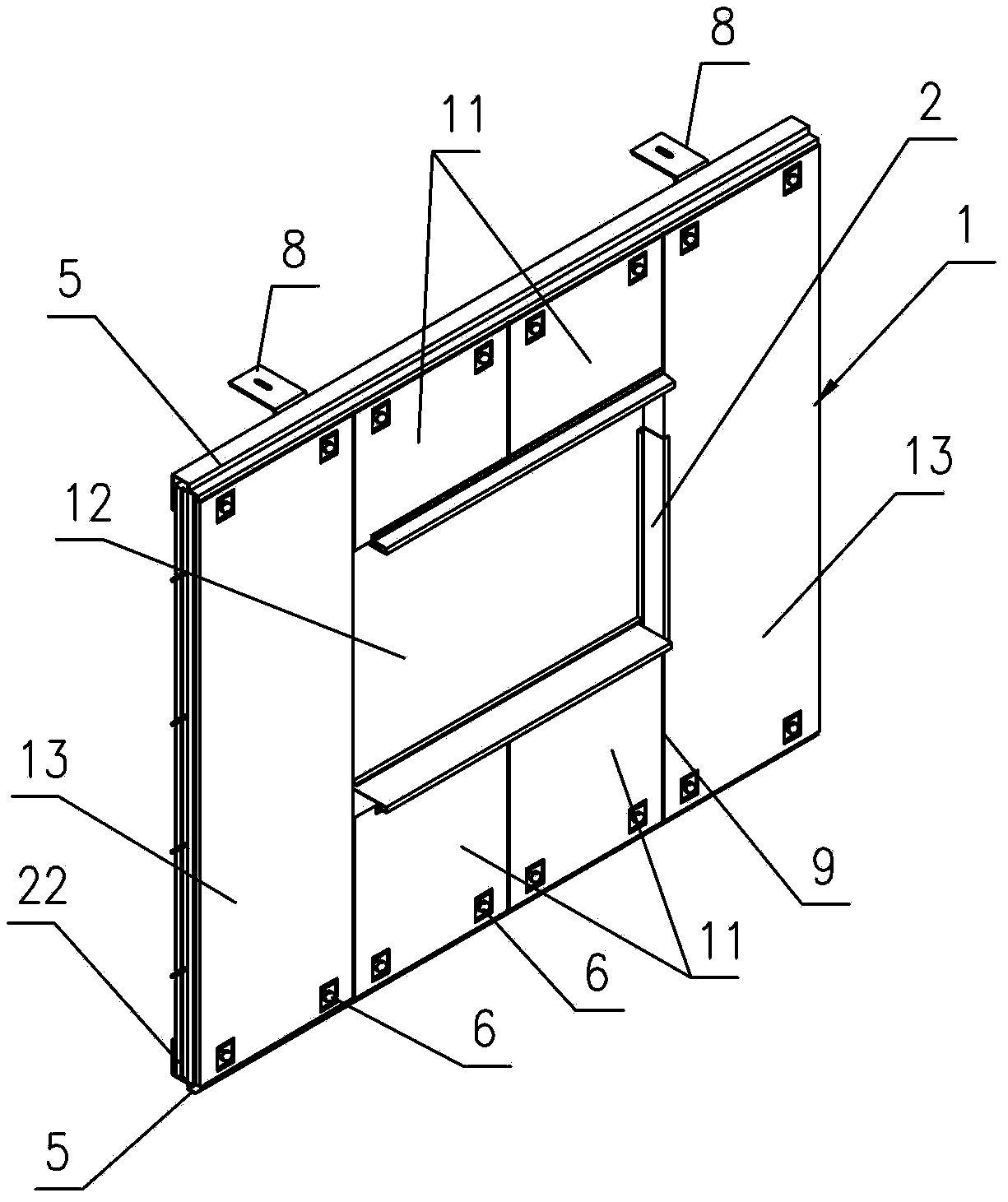

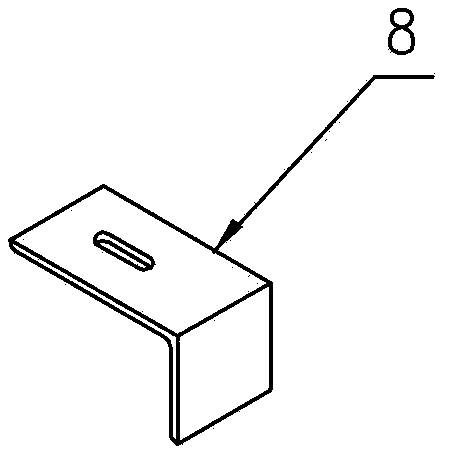

[0047] Such as Figure 2-6 As shown, it is a multifunctional combined lightweight concrete curtain wall of the present invention, which is mainly composed of lightweight concrete slab units 1 along the outer surface of the main building structure, and the lightweight concrete slab unit 1 consists of at least 2 lightweight concrete slabs Horizontally juxtaposed splicing, in this embodiment, the lightweight concrete slab is rectangular and adopts 6 pieces, that is, two groups of lightweight concrete slabs 11, 13 of different sizes, each lightweight concrete slab is in production, according to the load The parameters are equipped with structural steel bars, and the window opening 12 corresponding to the window 21 of the main structure of the building is reserved in the lightweight concrete slab unit 1, that is, the window opening 12 is surrounded by lightweight concrete slabs 11 and 13, wherein the window opening 12 There are a pair of horizontal lightweight concrete panels 11 on...

Embodiment 2

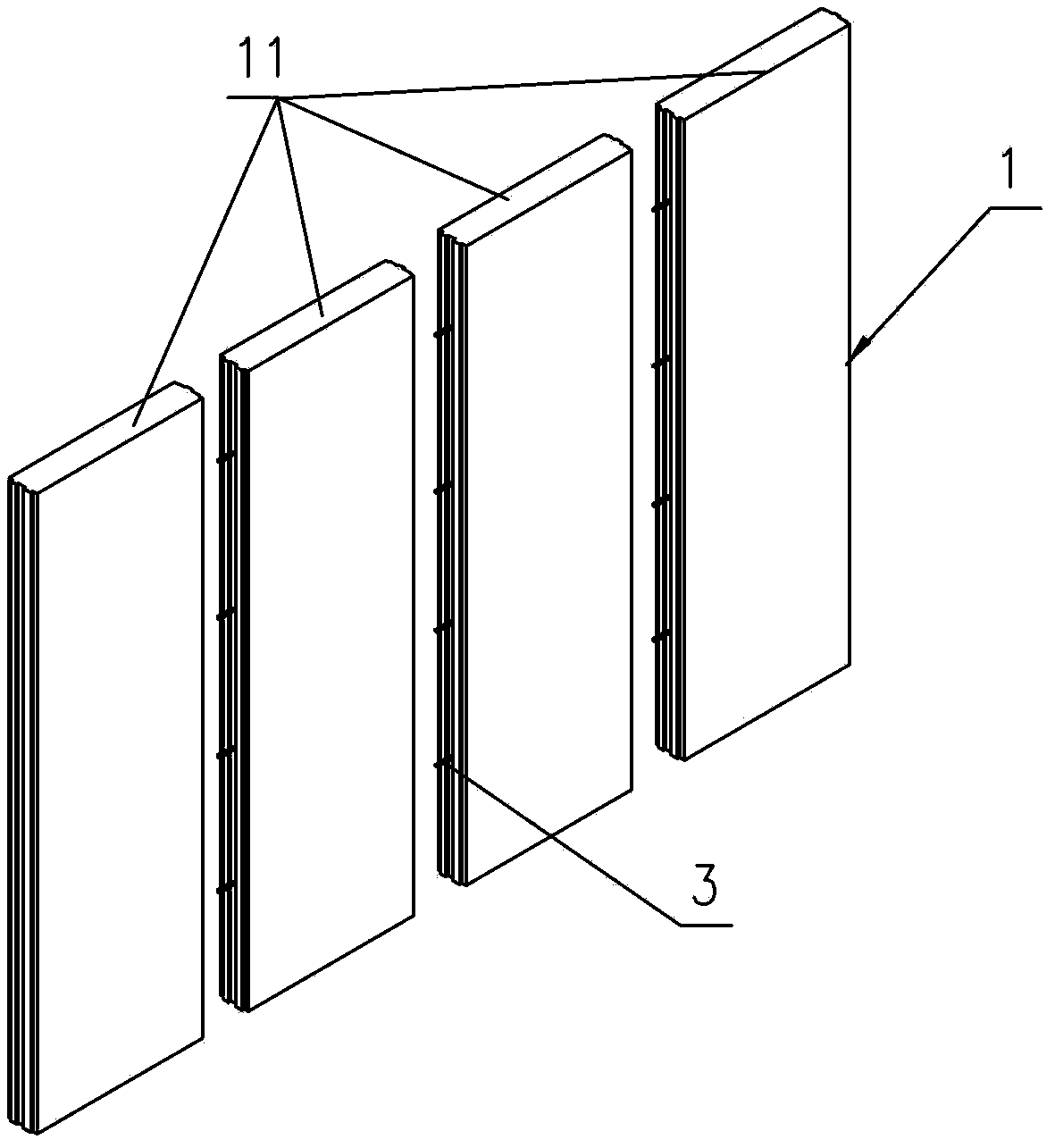

[0060] Such as figure 1 , 7 As shown, the difference between this embodiment and Embodiment 1 is that there is no window hole reserved on the lightweight concrete slab unit 1, and the lightweight concrete slab unit 1 is formed by splicing four rectangular lightweight concrete slabs 11 horizontally side by side. The lightweight concrete slabs 11 have the same size and are arranged vertically. Each lightweight concrete slab 11 is provided with a transverse through hole, corresponding to the through holes of each lightweight concrete slab 11, the steel bars 3 are penetrated laterally along the through holes of each lightweight concrete slab 11, and the adhesive is poured The steel bar 3 is anchored in the through hole to realize the splicing of the lightweight concrete slabs 11 . The decorative surface of this embodiment is formed by coating the exterior wall paint 23 .

[0061] In other embodiments, such as Figure 8 As shown, the decorative surface is made of stone 24, whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com