A sampling tool for substation oil-filled equipment

A technology for oil-filled equipment and substations, applied in sampling devices and other directions, can solve the problems of oil sample sputtering and quality degradation, and achieve the effect of strong anti-corrosion characteristics and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

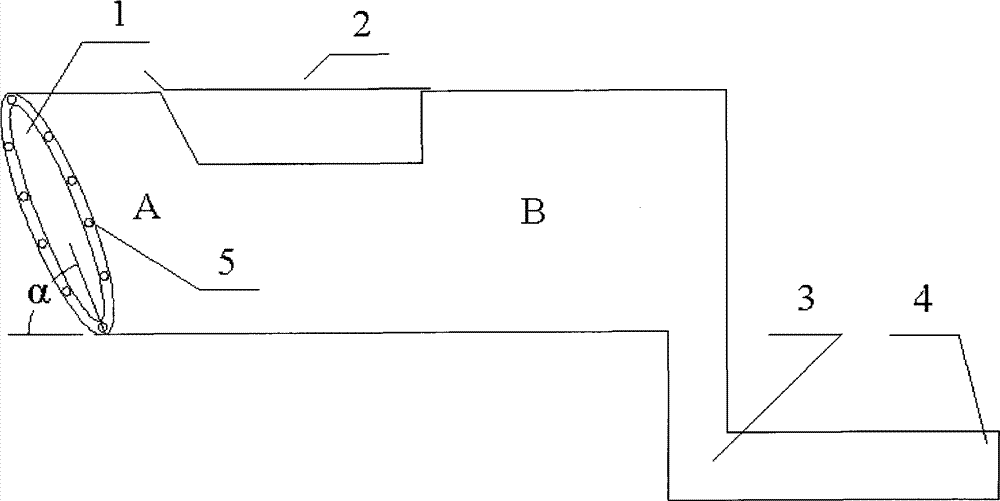

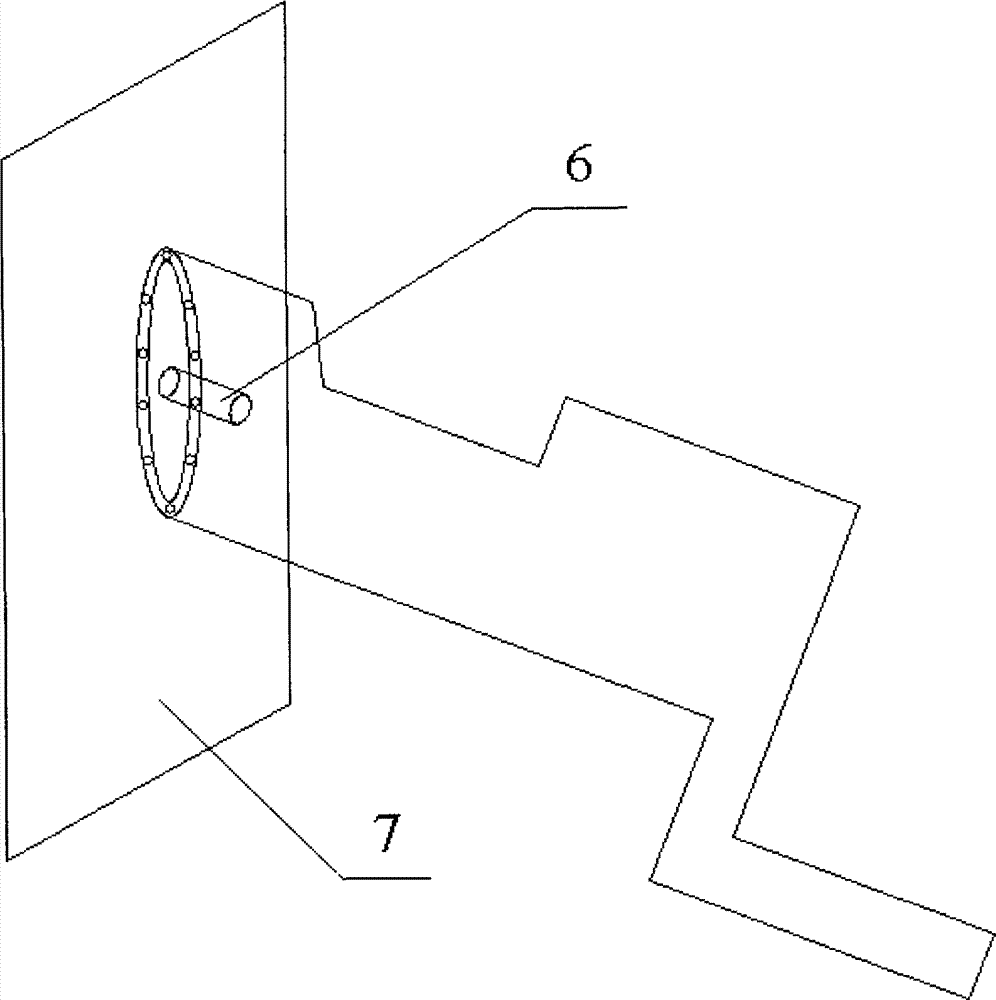

[0012] Attached below Figure 1-2 The present invention will be described in detail.

[0013] A sampling tool for substation oil-filled equipment. The sampling tool is made of stainless steel as a whole. The front end of the sampling tool is a hollow cylindrical structure. The upper inlet of the draft tube 3 is connected to the bottom of the rear end of the hollow cylindrical structure, and the lower outlet of the L-shaped draft tube is connected to the sampling bottle. Wherein the hollow cylindrical structure at the front end of the sampling tool has a larger diameter, and the L-shaped draft tube has a smaller diameter. The hollow cylindrical structure includes an adsorption area A at the front end and a buffer zone B at the rear end, wherein the port of the adsorption area A is the oil discharge valve interface 1, in order to avoid spillage and splashing of the oil sample during the sampling process, and at the same time to form a certain The inclination is convenient for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com