platform unit

A platform and positioning pin technology, applied in the direction of machine/stand, supporting machine, instrument, etc., can solve problems such as high cost and platform damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

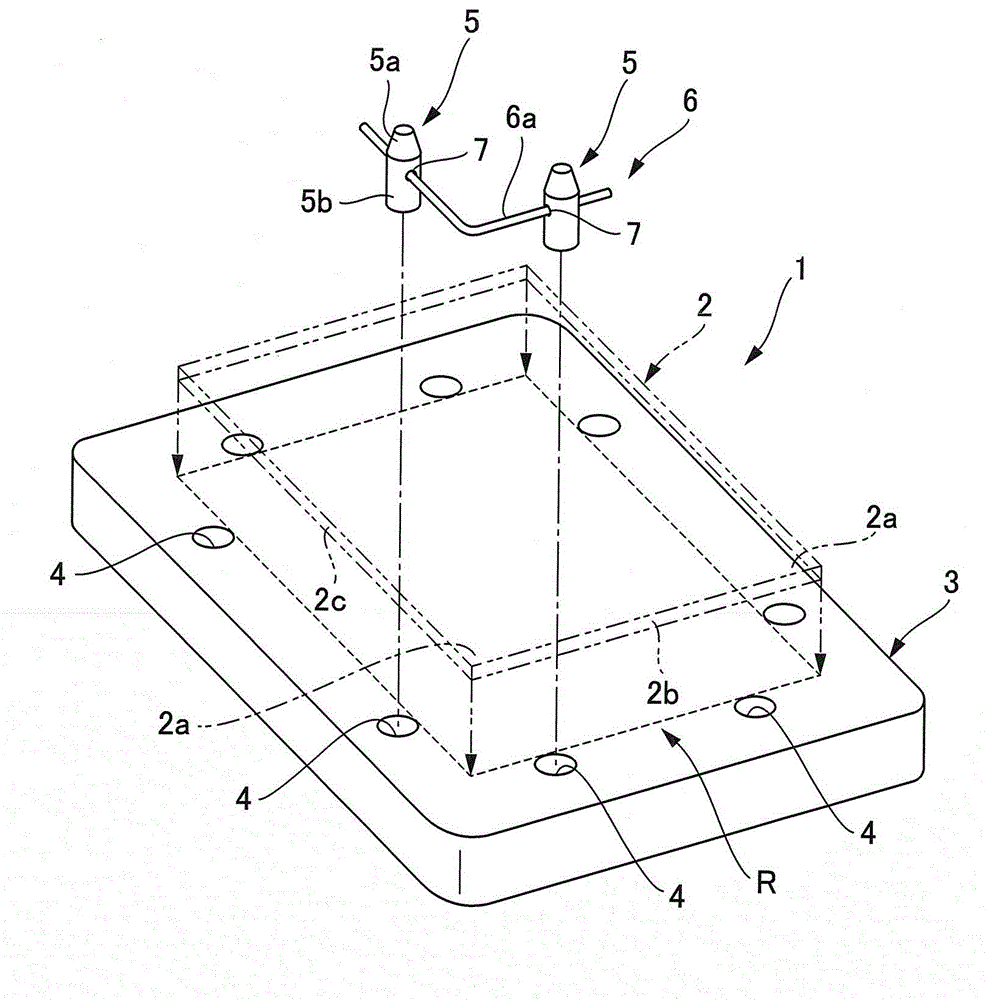

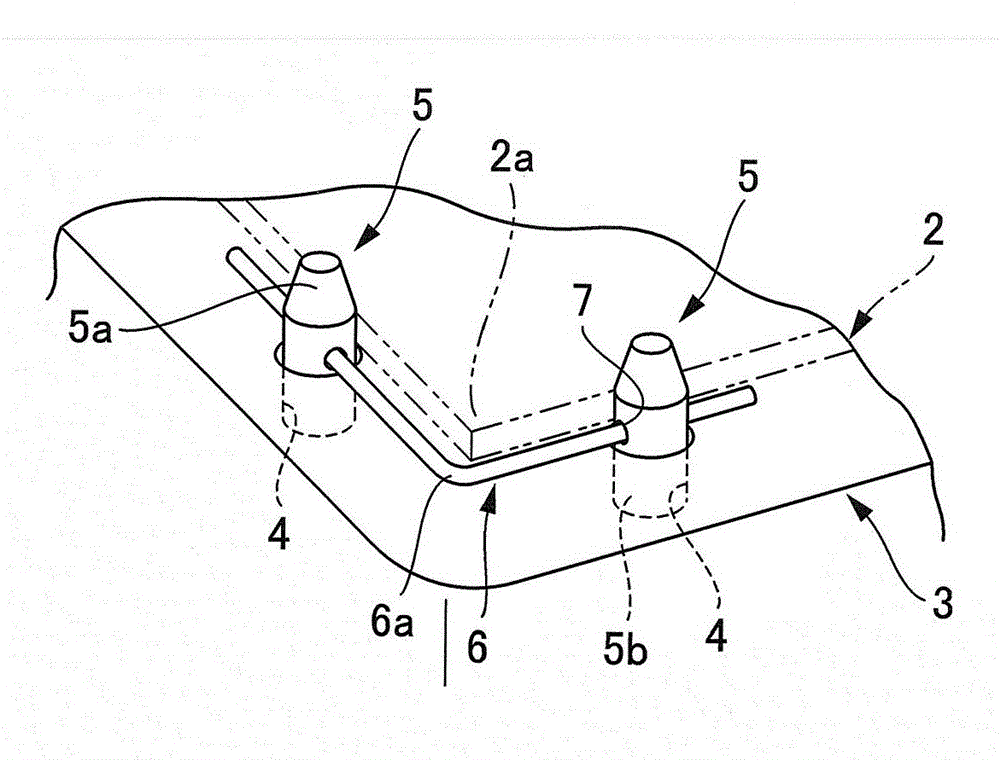

[0047] Hereinafter, preferred embodiments of the platform unit of the present invention will be described in detail with reference to the drawings. exist figure 1 The platform unit 1 of the first embodiment is shown in . For example, when heat-processing a thin-plate glass substrate 2 with a thickness of about 1 mm or less used in a portable communication device, the stage of the present embodiment is used when the glass substrate 2 is positioned on the stage 3 and transported into a heating furnace. Unit 1. In this embodiment, the stage unit 1 on which the rectangular glass substrate 2 is mounted is taken as an example and demonstrated.

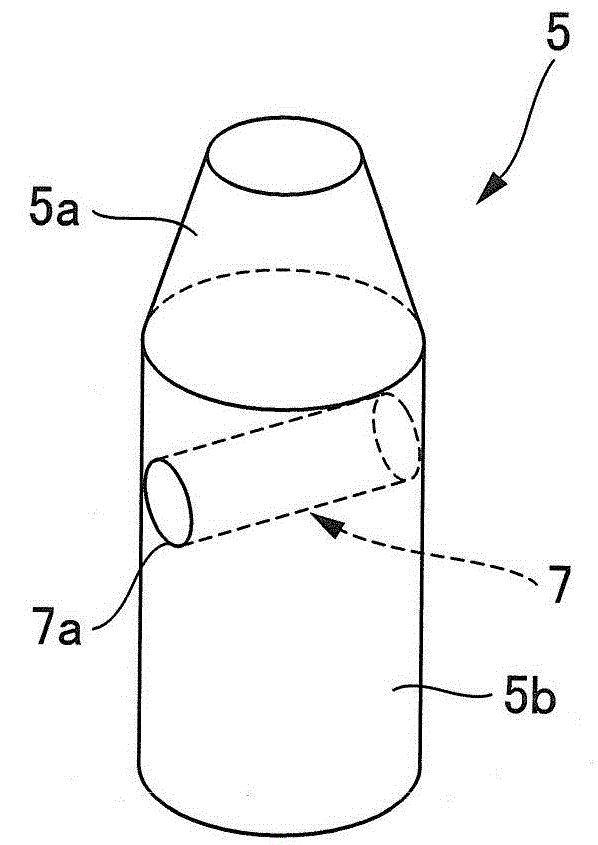

[0048] Such as figure 1 As shown, the platform unit 1 has: a platform 3 made of ceramics, on which a glass substrate 2 for heat treatment is placed; a plurality of loose holes 4, which are arranged on the platform 3 at positions where the glass substrate 2 is positioned, And the upward and downward direction is penetrated and formed; A p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com