Method for restraining torque pulsation of permanent magnet synchronous motor

A permanent magnet synchronous motor, torque ripple technology, applied in motor generator control, electronic commutation motor control, control generator and other directions, can solve the complex non-sinusoidal distortion, magnetic density distribution is not completely sinusoidal, affecting the motor control performance and other problems, to achieve the effect of increasing the compensation current and improving the compensation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

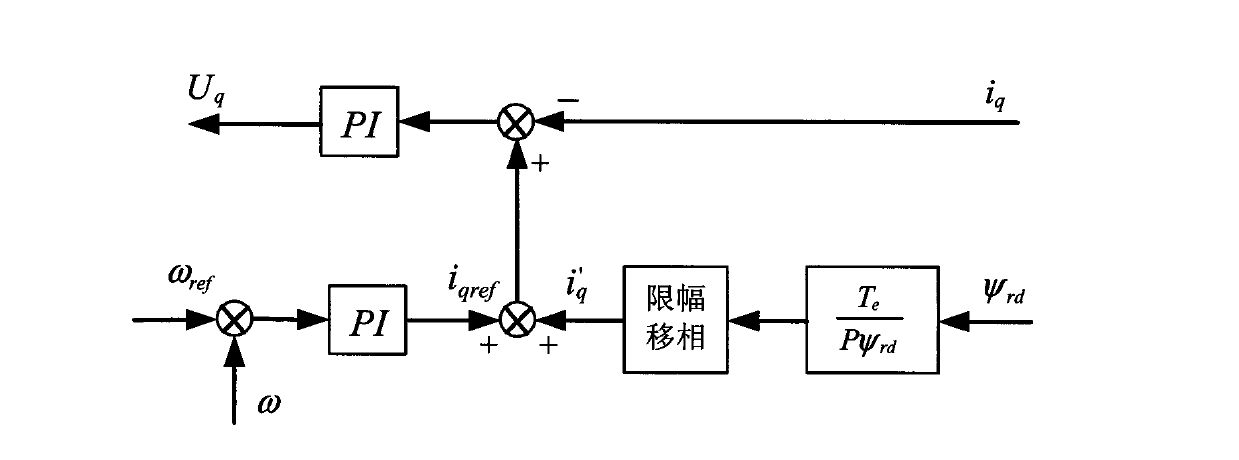

[0023] The method for suppressing the torque ripple of the permanent magnet synchronous motor provided by the present invention includes using the original reference signal and the q-axis current signal, and adopting the method of superimposing the q-axis current compensation to suppress the torque of the permanent magnet motor. The q-axis current compensation There are two method steps respectively:

[0024] (1) When the electromagnetic output torque T e Under a given condition, the q-axis compensation current can be calculated by the electromagnetic torque formula, and then superimposed with the original reference signal, then compared with the q-axis current and sent to the controller to output the q-axis voltage, the q-axis compensation current i' q The formula is:

[0025] i q ′ = T e Pψ rd

[0026] In the abov...

Embodiment 2

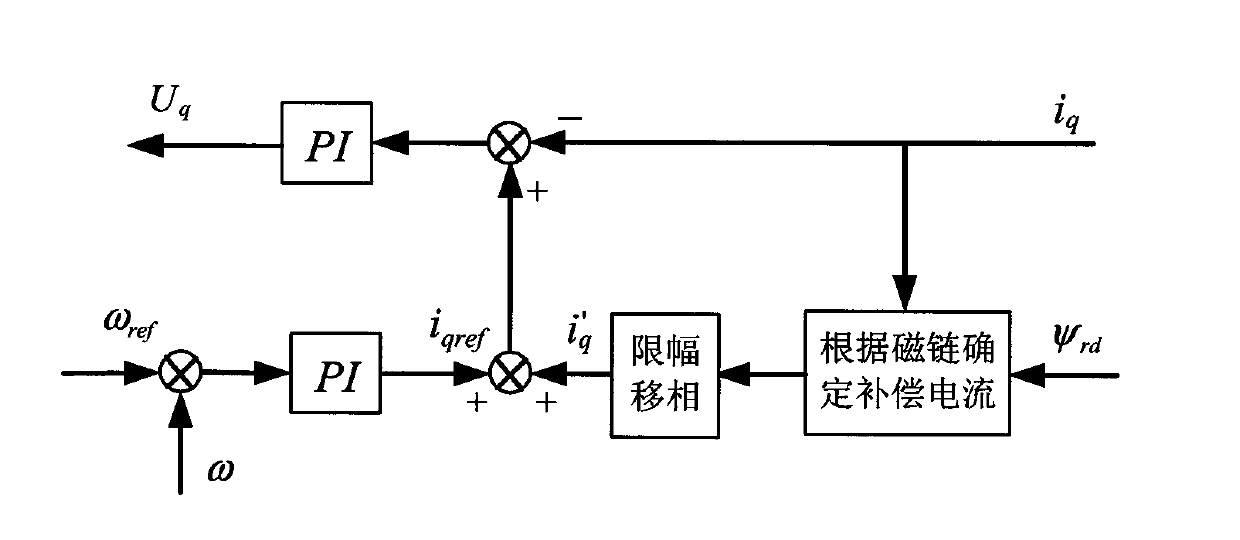

[0048] Since the first method is for a given given output torque T e , the compensation current i' of the q-axis can be accurately calculated q . Realize the current compensation, but not all occasions where the electromagnetic torque of the motor can be accurately known, the first method cannot be used to calculate the compensation current, so the method of determining and calculating the compensation current by flux linkage can be adopted. The circuit control block diagram is as follows figure 2 as shown,

[0049] At this time, i' in the control method q The formula of can be determined according to the flux linkage, and the formula is as follows:

[0050] i q ′ = β * ( ψ rd - ψ rd * ) ψ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com