Automatic winding apparatus for single-strand hard metal wire

A technology of hard metal and equipment, applied in the field of single-strand hard wire automatic winding equipment, can solve the problems of high energy consumption, high cost, complex structure, etc., and achieve the effects of reducing cost, simple structure, and easy manufacturing and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

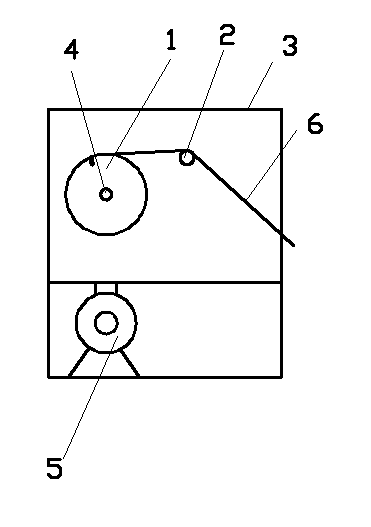

[0014] This embodiment provides a single-strand hard metal wire automatic winding equipment, which is characterized in that: the single-strand hard metal wire automatic winding equipment includes a winding roller 1, a forming column 2, a frame 3, a main shaft 4, a three-phase Asynchronous motor 5;

[0015] Among them: the winding roller 1 is installed on one end of the main shaft 4, the cylindrical winding shaft 2 is installed on the frame 3, the axis of the forming column 2 is parallel to the axis of the winding roller 1, the three-phase asynchronous motor 5 is installed on the frame 3, and the main shaft 4 and The three-phase asynchronous motors 5 are connected through a belt drive.

[0016] There is a radial slit on the winding roller 1, and one end of the single-strand hard metal wire 6 is clamped in the slit.

[0017] The single-strand hard metal wire 6 winds around the cylindrical winding shaft 2 in turn, and under the pulling action of the winding roller 1, forms a cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com