Rotary sealed material discharging device

A rotary sealing and discharging technology, applied in unloading devices, petroleum industry, coke ovens, etc., can solve the problems of no wear protection of countersunk head screws, wear of countersunk head, equipment shutdown, etc., to prevent damage to equipment caused by overload, Improve service life and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

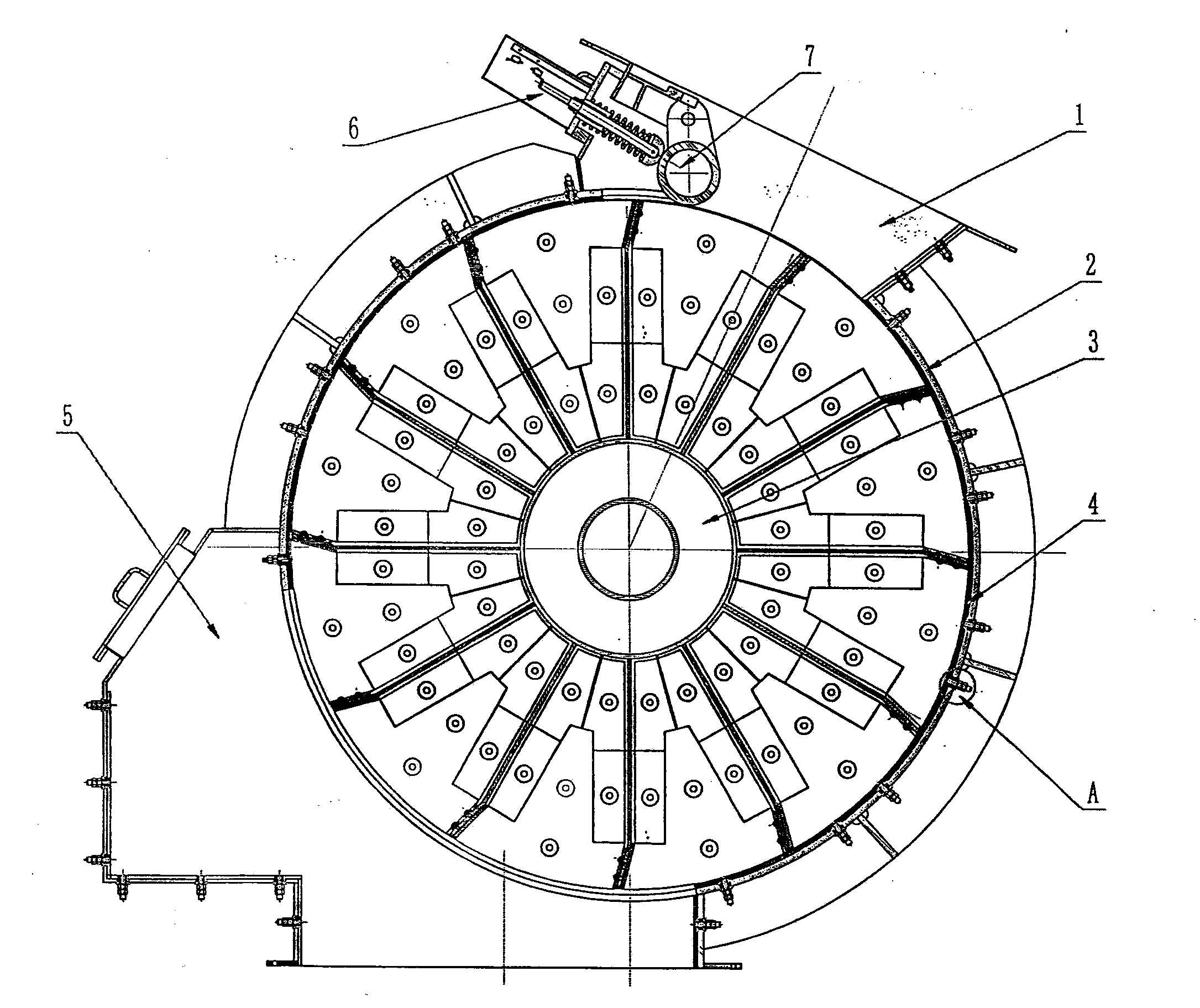

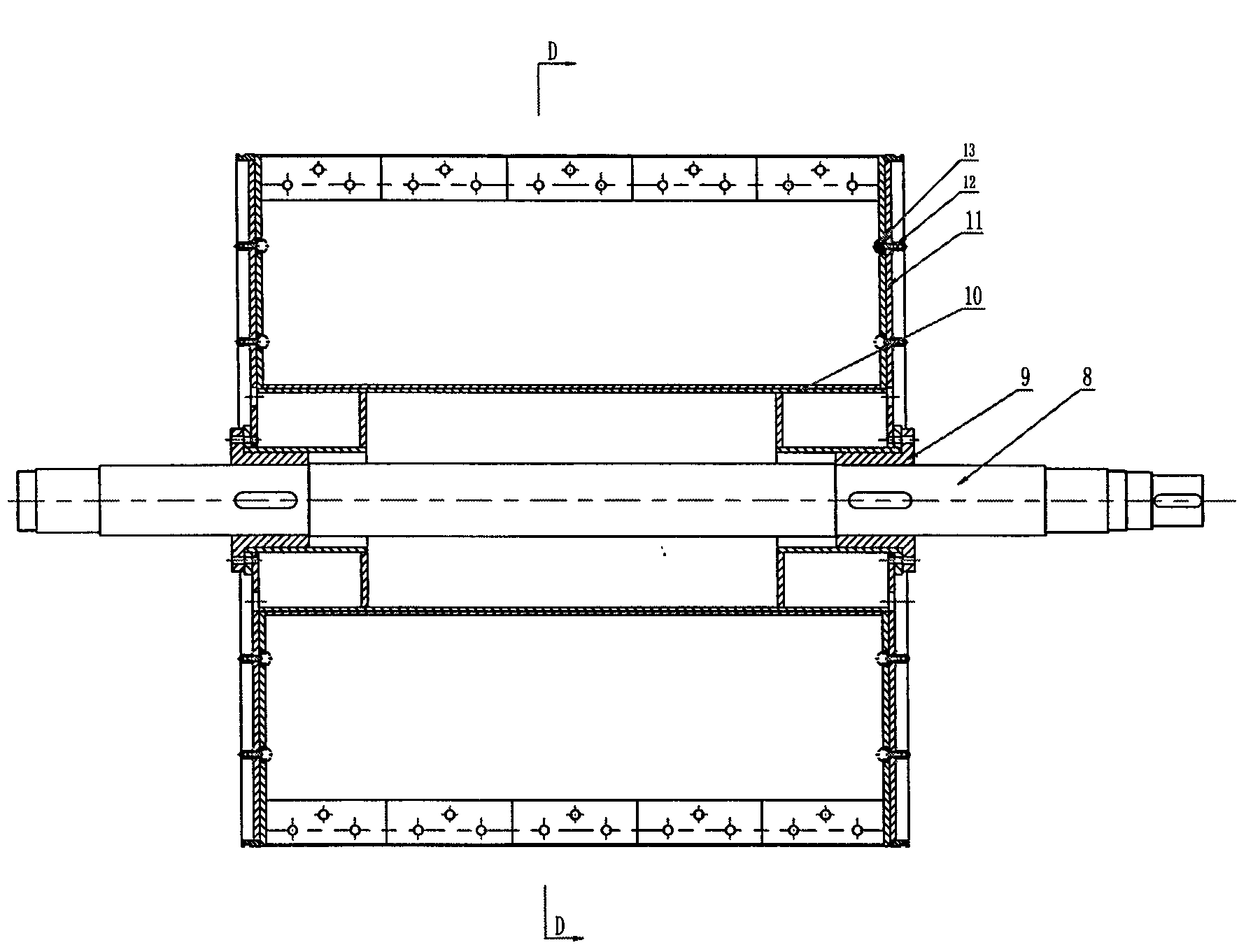

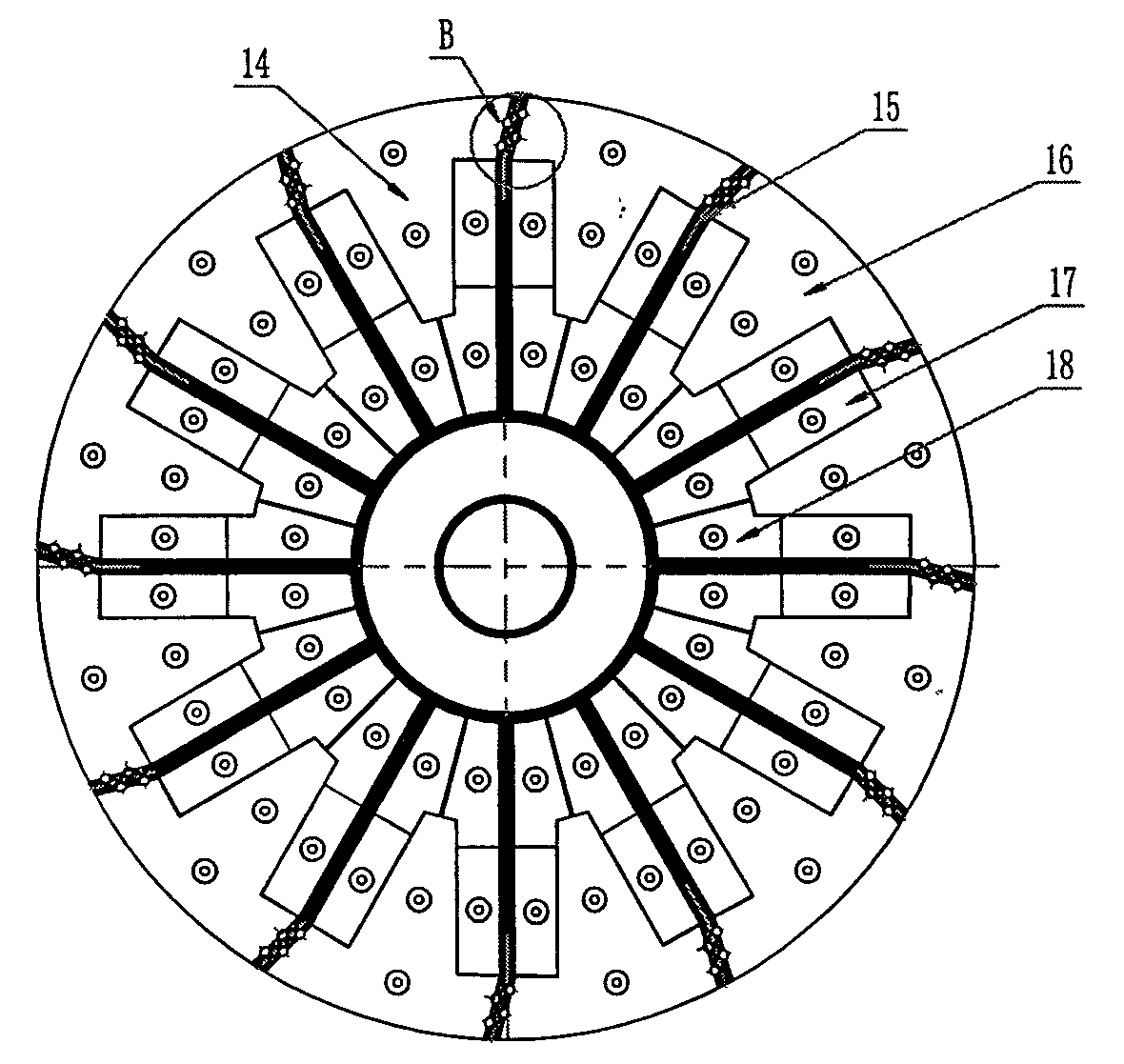

[0025] Such as figure 1 As shown, the rotary sealing discharge device includes a valve body 2 and a star-shaped rotor 3 located in the valve body 2. The valve body 2 is provided with a feed port 1 and a discharge port 5, and the star-shaped rotor 3 located in the feed port 1 An alarm cut-off device 6 and a buffer 7 are arranged above, and the star rotor 3 is installed in the valve body 2 through a coupling 9 and a transmission shaft 8, and the alarm cut-off device 6 and the The buffer 7 is fixed on the left side of the feed port 1, the adjusting blade 28 is installed on the star rotor 3 by adjusting the size of the top block 30 and the wear-resistant screw 29, and the movable head of the alarm cutter 6 is Next to part 61 and the buffer head 46, as the buffer head 46 on the buffer 7 rotates, the movable rod 55 installed on the movable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com