Color difference analysis equipment based on image recognition technology

A technology of color difference analysis and image recognition, which is applied in the direction of analyzing materials, instruments, and optical testing flaws/defects, etc. It can solve the problems of poor recognition quality, low efficiency, and large number of laborers, and achieve high recognition quality and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

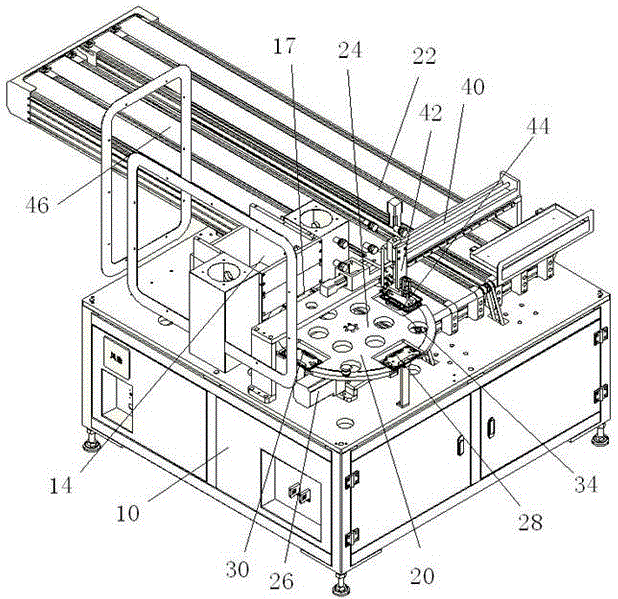

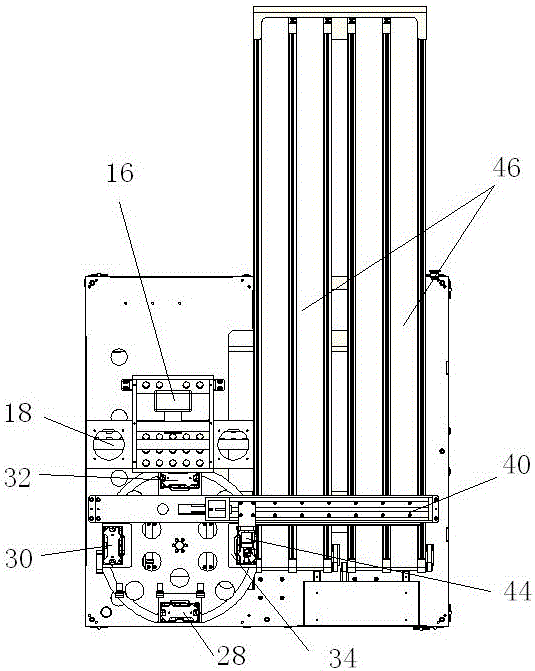

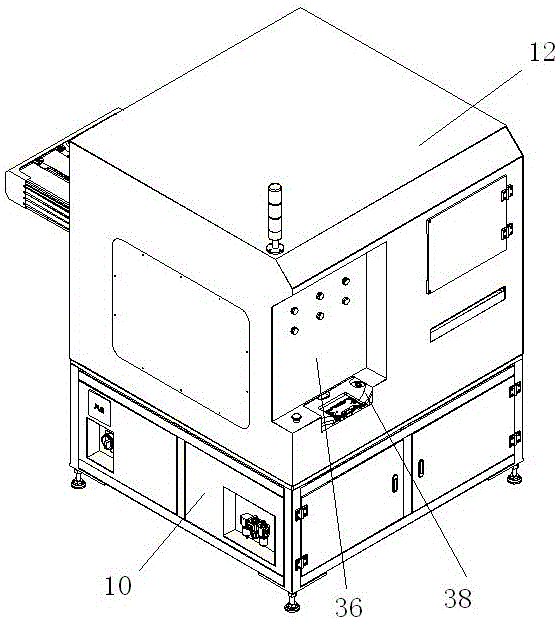

[0020] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0021] Such as Figure 1 to Figure 3 As shown, a color difference analysis device based on image recognition technology of the present invention includes a frame 10 on which a hollow casing 12 is disposed. A hollow camera room 14 is arranged in the housing 12, and a digital camera 16 for taking pictures of workpieces is arranged in the camera room 14. The digital camera 16 is connected with an image analysis device (not shown) for image color difference analysis, and the image analysis device performs color difference analysis. The camera room 14 is fully enclosed and only leaves an opening 17 for the workpiece to enter and exit. The camera ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com