Method for automatically forwardly/reversely tapering fiber

An optical fiber and translation stage technology, applied in cladding optical fibers, optical waveguides and light guides, etc., can solve the problems of optical fiber preparation technology that has not yet been discussed, and limit the optional range of optical fibers, achieving a high degree of automation, good repetition rate, and improved work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

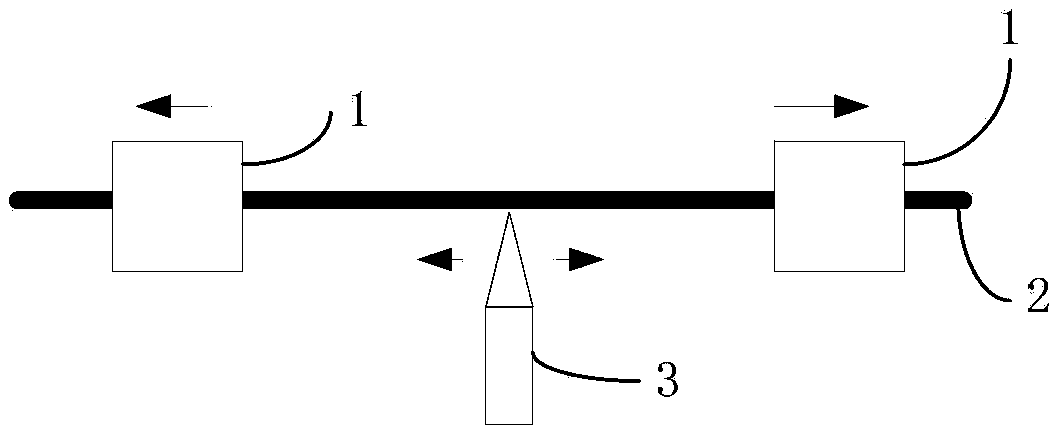

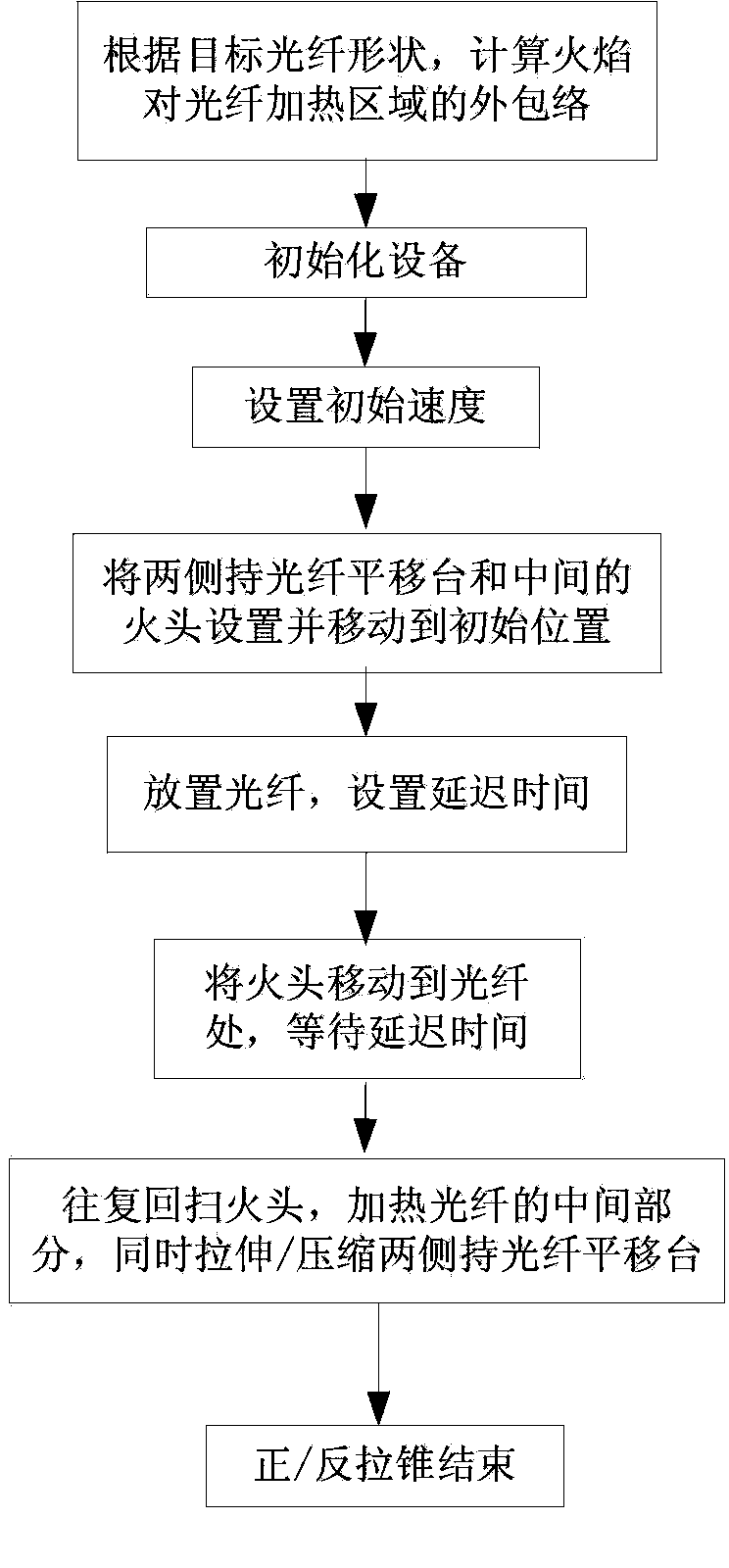

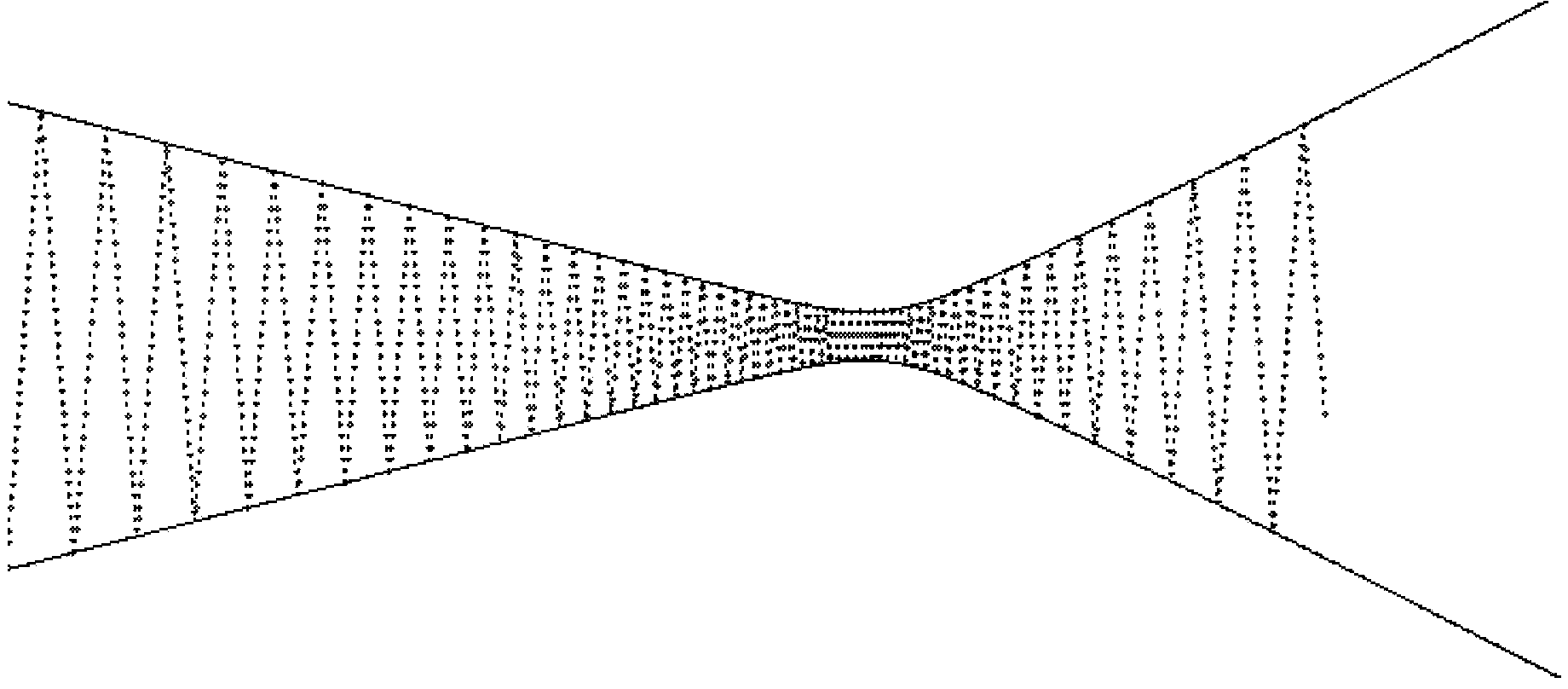

[0046] Such as figure 1 As shown, the process of forward tapering of optical fiber is that two ends of an optical fiber are clamped by two optical fiber translation stages, stretched to both ends, and at the same time, the flame reciprocally scans and heats the middle section of the optical fiber. In the reverse taper process, the movement direction of the translation stage holding the optical fiber is reversed. The movement of the two optical fiber translation stages and the middle fire head is controlled by stepping motors. Since only relative stretching and shrinking motions are required between the two translation platforms, they can be controlled by one stepping motor, and the movement of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com