Preparation method and application of safe and efficient potassium metal electrode material

A metal electrode, high-efficiency technology, applied in battery electrodes, alkali metal compounds, chemical instruments and methods, etc., can solve problems such as poor stability, potential safety hazards, fire, etc., achieve high repetition rate, improve safety, and convenient preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

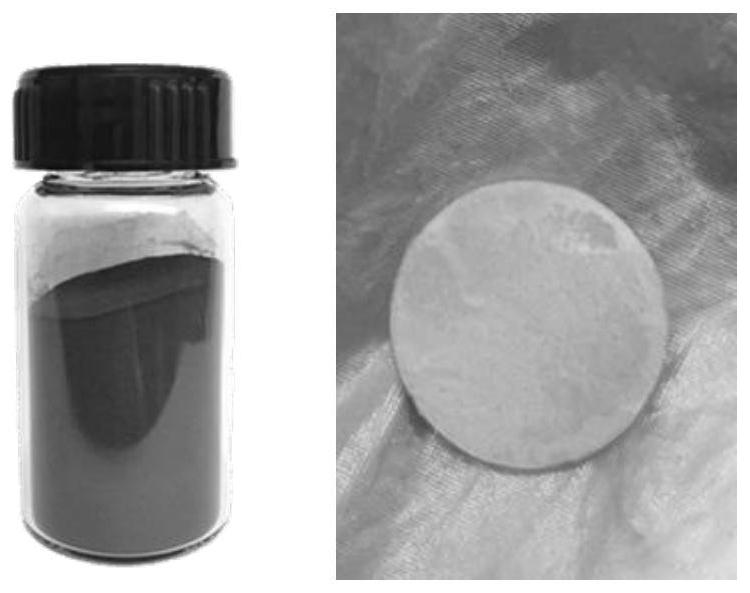

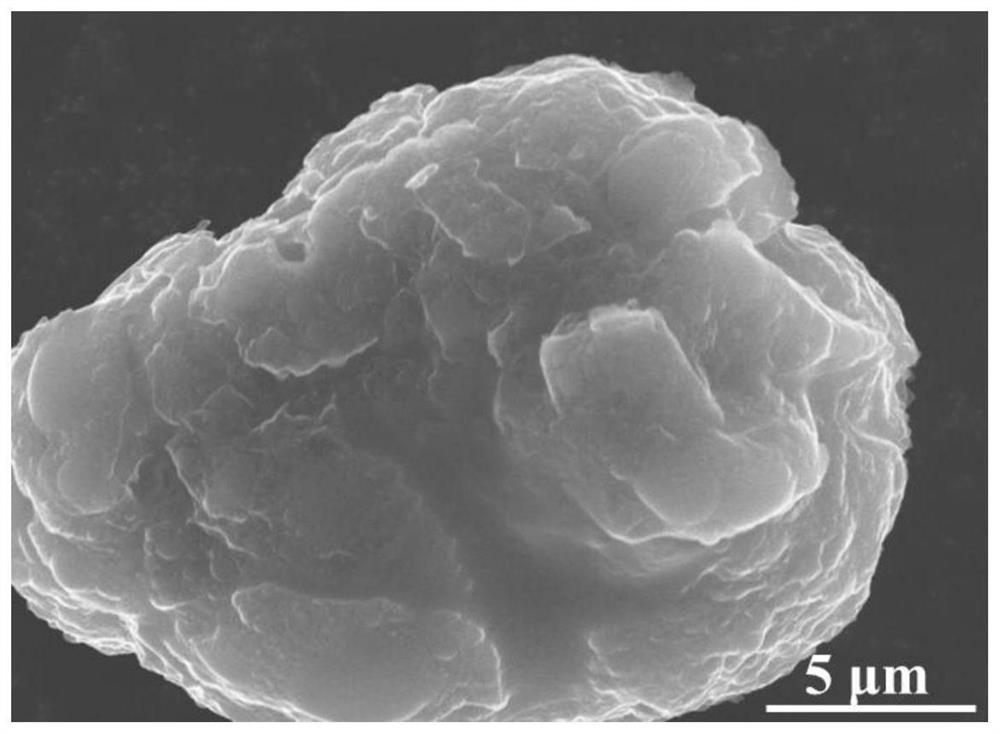

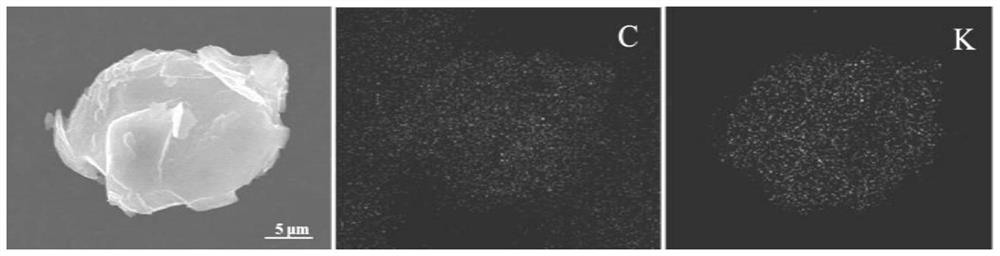

[0034] 1) Under the protection of argon, put 2.46g of dried natural graphite into the crucible container, raise the temperature to 350°C and keep stirring for 1min, so that the carbon material is heated evenly;

[0035] 2) Under the protection of argon, put 1 g of metal potassium after removing the oxide film into a crucible and mix it with the carbon material, and stir continuously at 350° C. to make the reaction continue. After stirring for 10 minutes, the potassium carbon compound is prepared;

[0036] 3) Under the protection of argon, the potassium carbon compound powder was pressed at a pressure of 0.5 t for 1 min to prepare a potassium carbon compound sheet, and a safe and efficient negative electrode material for a potassium metal battery was obtained.

Embodiment 2

[0039] 1) Under the protection of nitrogen gas, put 2.46g of dried natural graphite into the crucible container, raise the temperature to 350°C and keep stirring for 1min, so that the carbon material is heated evenly;

[0040] 2) Under the protection of nitrogen gas, put 1 g of metal potassium after removing the oxide film into a crucible and mix it with carbon materials, and stir continuously at 350°C to make the reaction continue to occur. After stirring for 10 minutes, a potassium carbon compound is prepared;

[0041] 3) Under the protection of nitrogen, the potassium carbon compound powder is coated on the copper sheet to prepare the potassium carbon compound electrode, and a safe and efficient negative electrode material for the potassium metal battery is obtained.

Embodiment 3

[0043] 1) Under the protection of argon gas, put 4.92g of dried natural graphite into the crucible container, raise the temperature to 350°C and keep stirring for 1min, so that the carbon material is heated evenly;

[0044] 2) Under the protection of argon gas, put 1 g of metal potassium after removing the oxide film into a crucible and mix it with the carbon material, and stir continuously at 350°C to make the reaction continue. After stirring for 10 minutes, the potassium carbon compound is prepared;

[0045]3) Under the protection of argon, the potassium carbon compound powder was held at a pressure of 0.2 t for 1 min to prepare a potassium carbon compound sheet, and a safe and efficient negative electrode material for a potassium metal battery was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com