a kind of yb 3+ Activated cubic structure upconversion luminescent material and its preparation method and application

A technology of luminescent material and cubic structure, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of poor chemical stability of halides and fluorides, high synthesis conditions, unfavorable practical applications, etc., and achieves good repetition rate and low cost. , the effect of low price of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] a Yb 3+ Activated cubic structure upconversion luminescent material, its chemical structure is Ba 3 Lu 1.89 Yb 0.1 Er 0.01 Zn 5 o 11 , prepared by the following preparation method.

[0035] Barium carbonate, lutetium oxide, zinc oxide, ytterbium oxide, and erbium oxide are selected as starting materials, and the molar ratio of each element is Ba:Lu:Zn:Yb:Er =3:1.89:5:0.1:0.01, corresponding to x=0.1 , y=0.01, 5 kinds of raw materials were weighed respectively, and the total weight of the raw material mixture was controlled to be 20 grams. Carry out thorough grinding and mixing, put it into a high-temperature furnace, bake at 1300°C for 4 hours, take it out when it is cooled to room temperature, and obtain a Yb after grinding and dispersing 3+ Activated cubic structure upconversion luminescent material composed of Ba 3 Lu 1.89 Yb 0.1 Er 0.01 Zn 5 o 11 .

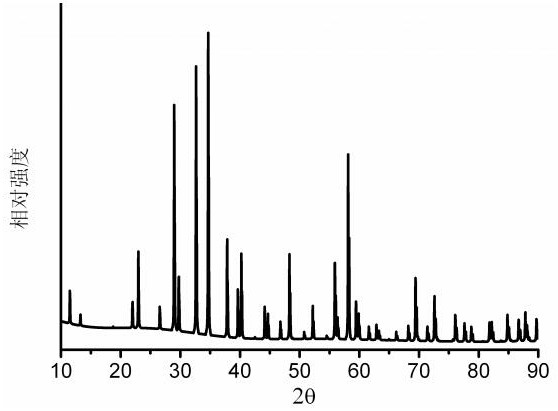

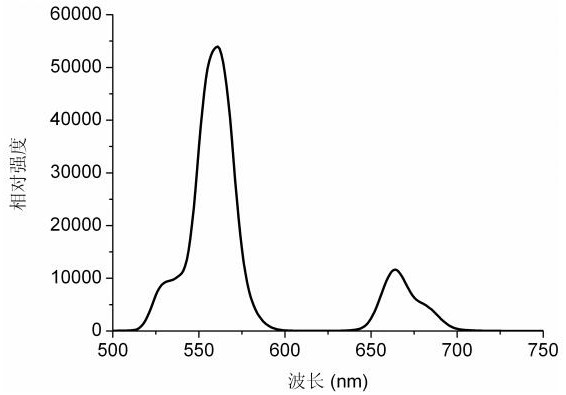

[0036] figure 1 It is the XRD pattern of the up-conversion luminescent material obtained in Example 1 ...

Embodiment 2

[0038] a Yb 3+ Activated cubic structure upconversion luminescent material, its chemical structure is Ba 3 Lu 1.89 Yb 0.1 Ho 0.01 Zn 5 o 11 , prepared by the following preparation method.

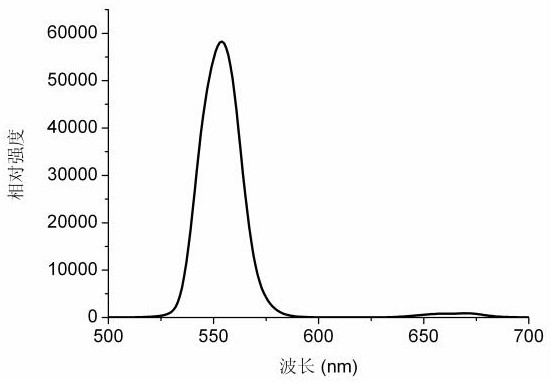

[0039] Barium carbonate, lutetium oxide, zinc oxide, ytterbium oxide, and holmium oxide are selected as starting materials, and the molar ratio of each element is Ba:Lu:Zn:Yb:Ho =3:1.89:5:0.1:0.01, corresponding to x=0.1 , y=0.01, 5 kinds of raw materials were weighed respectively, and the total weight of the raw material mixture was controlled to be 20 grams. Carry out thorough grinding and mixing, put it into a high-temperature furnace, bake at 1400°C for 2 hours, take it out when it is cooled to room temperature, and obtain a Yb after grinding and dispersing 3+ Activated cubic structure upconversion luminescent material composed of Ba 3 Lu 1.89 Yb 0.1 Ho 0.01 Zn 5 o 11 . image 3 It is the luminescence spectrum diagram of the green up-conversion luminescent material obtaine...

Embodiment 3

[0041] a Yb 3+ Activated cubic structure upconversion luminescent material, its chemical structure is Ba 3 Lu 1.89 Yb 0.1 T m0.01 Zn 5 o 11 , prepared by the following preparation method.

[0042] Barium carbonate, lutetium oxide, zinc oxide, ytterbium oxide, and thulium oxide are selected as starting materials, and the molar ratio of each element is Ba:Lu:Zn:Yb:Tm =3:1.89:5:0.1:0.01, corresponding to x=0.1 , y=0.01, 5 kinds of raw materials were weighed respectively, and the total weight of the raw material mixture was controlled to be 20 grams. Carry out thorough grinding and mixing, put it into a high-temperature furnace, bake it at 1250°C for 10 hours, take it out when it is cooled to room temperature, and obtain a Yb after grinding and dispersing 3+ Activated cubic structure upconversion luminescent material composed of Ba 3 Lu 1.89 Yb 0.1 T m 0.01 Zn 5 o 11 . Figure 4 It is the luminescence spectrum diagram of the blue up-conversion luminescent material obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com