Passive filter for realizing solid liquid gas phase separation

A passive filter and phase separation technology, applied in the direction of filtration separation, separation method, filtration circuit, etc., can solve the problems of material loss, separation difficulty, burns, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

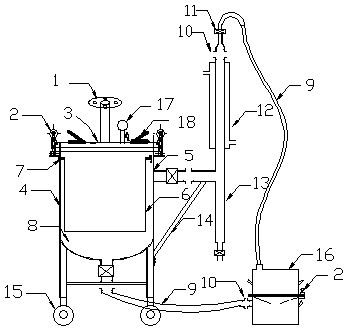

[0032] Prepare a passive filter made of 316L material. The main part of the washing machine is mainly composed of a phase separation part 4, a liquid phase collection chamber 8, a receiving tank 16, a gas phase outlet 5, a condenser 12, and a condensate collection chamber 13, which include a basket-shaped filter screen 6 with an opening facing upwards. Auxiliary parts such as some valves 11, quick connectors 10 and hoses 9 are combined, wherein,

[0033] There is a cover 3 on the phase separation part 4, a handle 18 on the cover 3, fastening bolts 2 are arranged around the cover 3, and a sealing ring is arranged between the cover 3 and the side wall of the phase separation part 4;

[0034] There is a connecting pipe guided by the flange 1 on the cover 3;

[0035] The basket-shaped filter screen 6 with the opening facing upwards is spot-welded on the bracket. The bracket has flanging and a handle, and is placed on the filter screen support ring 7 of the inner wall opening of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com