Solar photo-thermal glass bending furnace

A technology of solar energy and hot bending furnace, which is applied in glass forming, glass tempering, glass manufacturing equipment, etc. It can solve the problems of inability to realize solar photothermal glass quenching, glass strength is difficult to meet the use requirements, etc., and achieve strength improvement, strength Large, evenly curved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

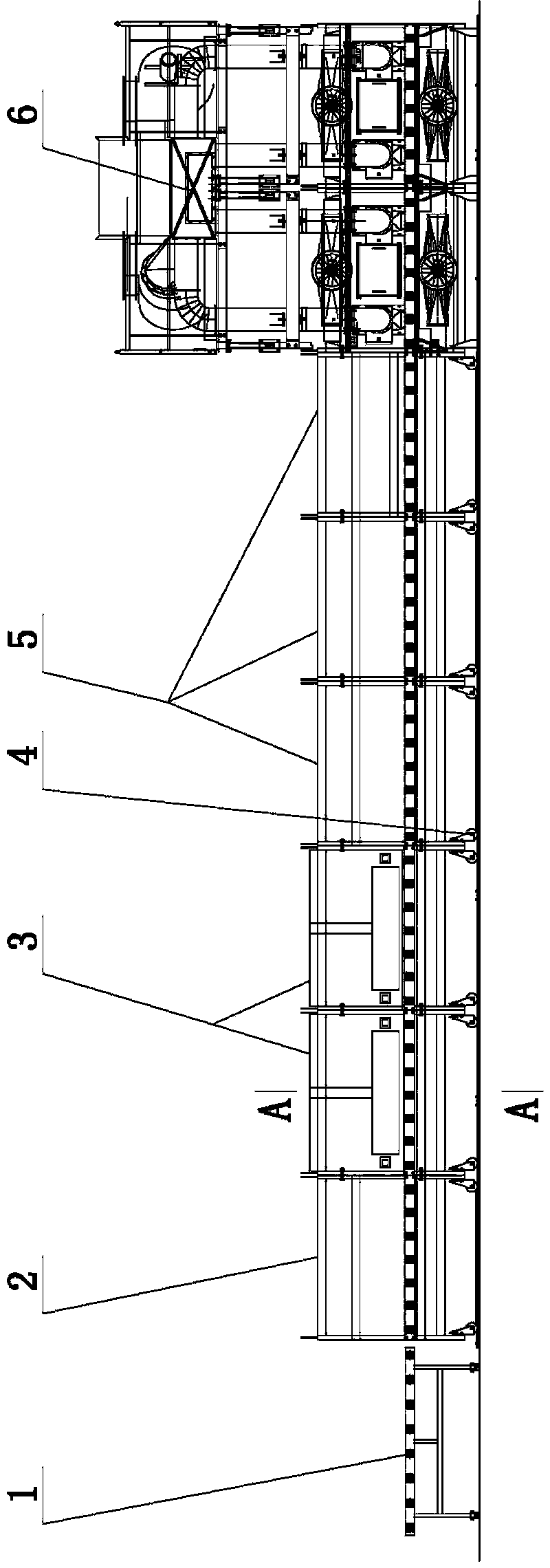

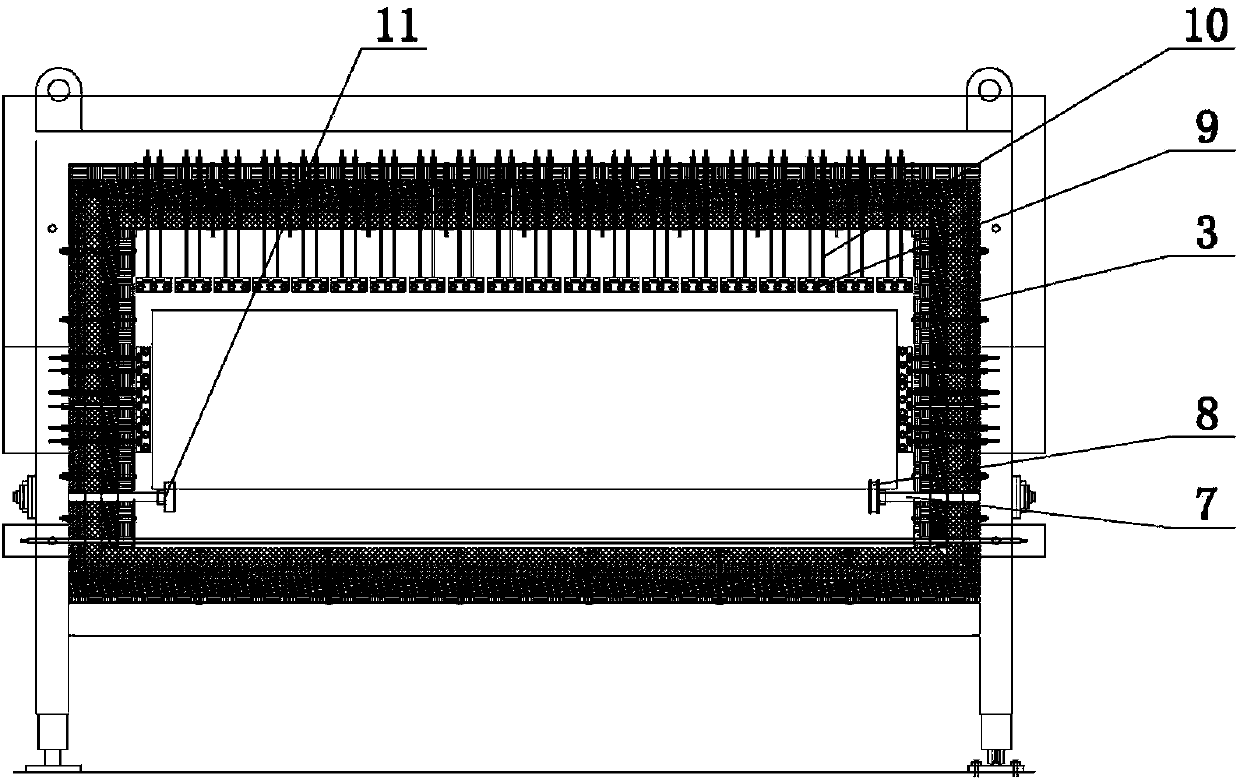

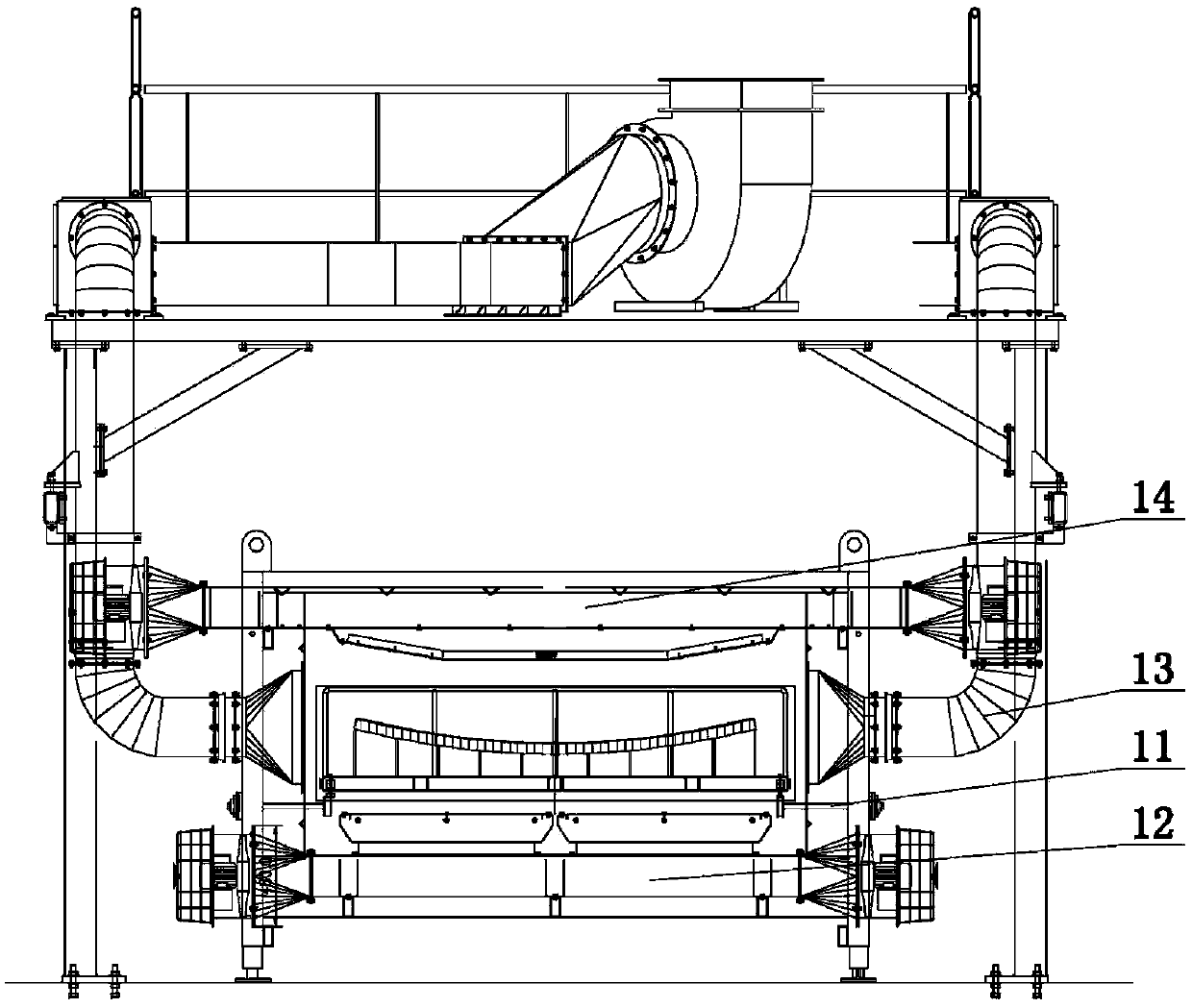

[0020] The present invention includes a preheating chamber 2 and a thermoforming chamber 3, and is characterized in that: a cooling transition chamber 5 and a strong cooling chamber 6 are sequentially arranged behind the thermoforming chamber 3; the preheating chamber 2, thermoforming chamber 3, and cooling transition chamber 5 and both sides of the strong cooling chamber 6 are provided with supporting transmission devices 11; the thermoforming chamber 3 is provided with heating wires 9 in the four directions of up, down, left, and right.

[0021] As a preferred solution of the present invention, the heating wires 9 on the upper side and on the left and right sides in the thermoforming chamber 3 are arranged in the thermoforming chamber 3 through the length adjusting rod 10 .

[0022] Heating wires 9 are arranged above and below the preheating chamber 2 .

[0023] The upper heating wire 9 in the preheating chamber 2 is arranged in the thermoforming chamber 3 through a length a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com