Environment-friendly low-alkali CL-free accelerator

An accelerator and environment-friendly technology, applied in the field of accelerator, can solve the problems of less application and high price, achieve good activity, low density, and reduce the standard consistency of cement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

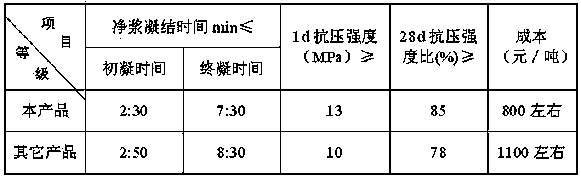

Examples

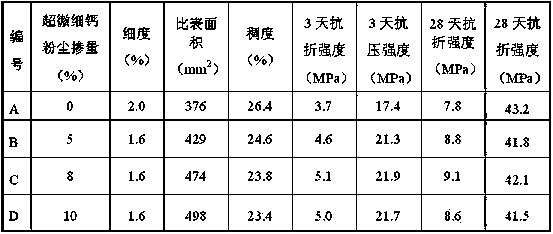

Embodiment 1

[0020] Example 1 Environmentally friendly low-alkali and CL-free - Accelerator, it is made of the following weight percentage (kg / kg) after the raw materials are mixed evenly, after grinding, passing through a 0.08mm square empty sieve, so that the sieve rate is less than 15%, that is, the accelerator product: fluorinated Sodium 4%, sodium aluminate 14%, high aluminum fly ash 5.8%, ultrafine calcium dust 75% and polyvinyl alcohol 24-88 1.2%.

Embodiment 2

[0021] Example 2 Environmentally friendly low-alkali and CL-free - Accelerator, it is made of the following weight percentage (kg / kg) after the raw materials are mixed evenly, after grinding, passing through a 0.08mm square empty sieve, so that the sieve rate is less than 15%, that is, the accelerator product: fluorinated Sodium 10%, sodium aluminate 11%, high aluminum fly ash 18%, ultrafine calcium dust 60% and polyvinyl alcohol 24-88 1%.

Embodiment 3

[0022] Example 3 Environmentally friendly low-alkali and CL-free - Accelerator, it is made of the following weight percentage (kg / kg) after the raw materials are mixed evenly, after grinding, passing through a 0.08mm square empty sieve, so that the sieve rate is less than 15%, that is, the accelerator product: fluorinated Sodium 16%, sodium aluminate 8%, high aluminum fly ash 30.2%, ultrafine calcium dust 45% and polyvinyl alcohol 24-88 0.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com