High-strength tile and preparation method thereof

A production method and high-strength technology, applied in the field of ceramic tiles, can solve problems such as inapplicability and unsatisfactory impact resistance, and achieve the effects of improving safety in use, novel style, and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

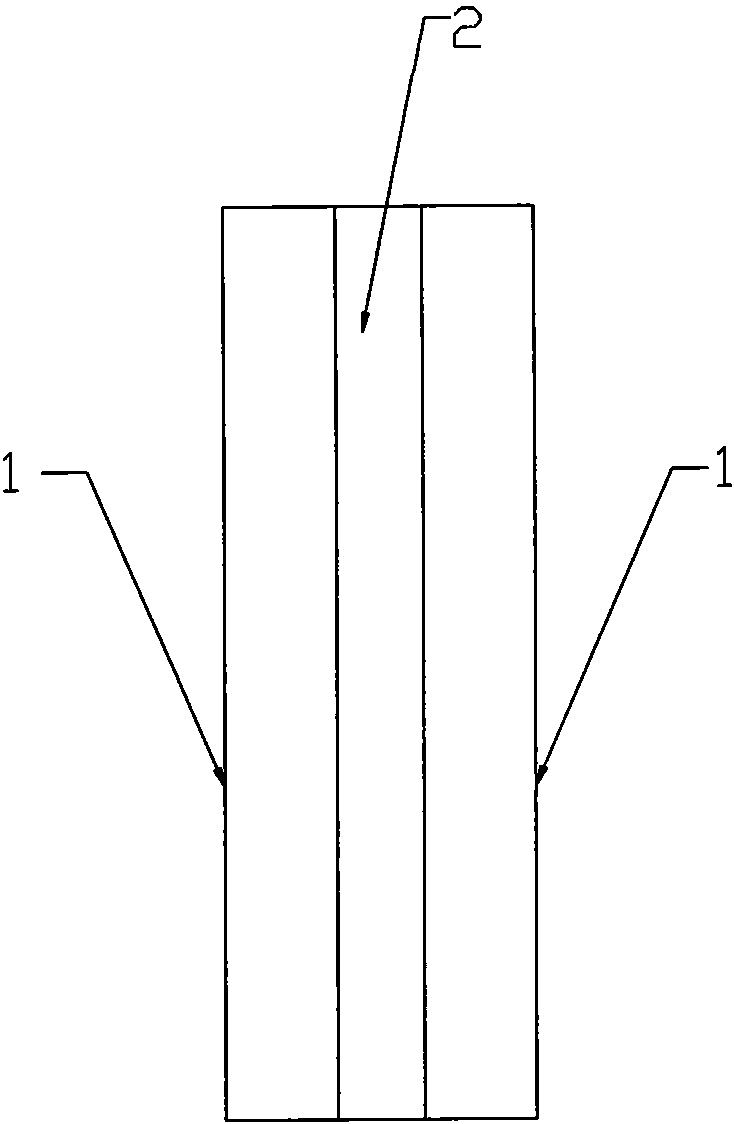

[0022] figure 1 As shown, the high-strength tile of the present invention includes two tile bodies 1, and the two tile bodies 1 are connected by PVB, EVA, SGP or TPU film 2, and the thickness of the PVB, EVA, SGP or TPU film 2 is 0.76mm.

[0023] The manufacturing method of high-strength ceramic tile of the present invention comprises the following steps:

[0024] 1) Polishing, cleaning and drying the two ceramic tile bodies 1;

[0025] 2) The two ceramic tile bodies 1 treated in step 1) are bonded by PVB, EVA, SGP or TPU film 2;

[0026] 3) After step 2), the two tile bodies 1 that have been bonded are sent to a roller press for hot rolling to remove the air between the two tile bodies 1, and the temperature of the high-temperature roller of the roller press is higher than that of the low-temperature roller 20°C, the surface temperature of the two ceramic tile bodies 1 after hot rolling reaches 40°C;

[0027] 4) The two ceramic tile bodies 1 that have been hot rolled in s...

Embodiment 2

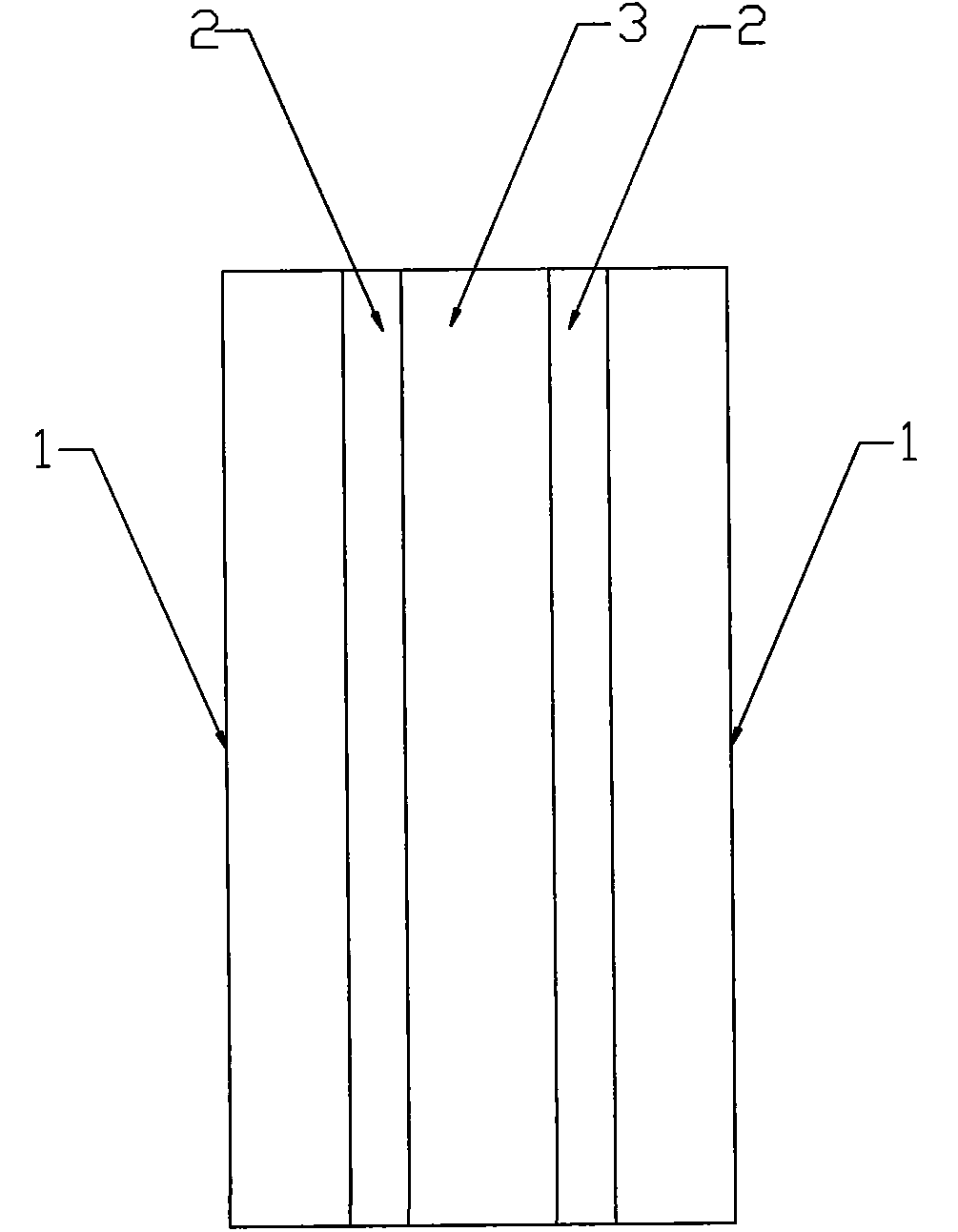

[0031] Such as figure 2 As shown, the high-strength ceramic tile of the present invention includes two tile bodies 1, a glass 3 is arranged between the two tile bodies 1, and a PVB, EVA, SGP or TPU film 2 is passed between the adjacent tile bodies 1 and the glass 3 Connected, the thickness of the PVB, EVA, SGP or TPU film 2 is 1.52mm, and the thickness of the glass 3 is 12mm.

[0032] The manufacturing method of high-strength ceramic tile of the present invention comprises the following steps:

[0033] 1) Polishing, cleaning and drying the two ceramic tile bodies 1;

[0034] 2) The two tile bodies 1 and the glass 3 treated in step 1) are bonded by PVB, EVA, SGP or TPU film 2;

[0035] 3) After step 2), the two tile bodies 1 that have been bonded are sent to a roller press for hot rolling to remove the air between the two tile bodies 1, and the temperature of the high-temperature roller of the roller press is higher than that of the low-temperature roller 30°C, the surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com