On-line powder flowing measurement device and method based on array type static sensor

An electrostatic sensor and measuring device technology, which is applied in the direction of using an electric/magnetic device to transmit sensing components, etc., can solve the problems of inability to measure powder flow parameters in all directions, and inability to provide powder flow characteristics and laws.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

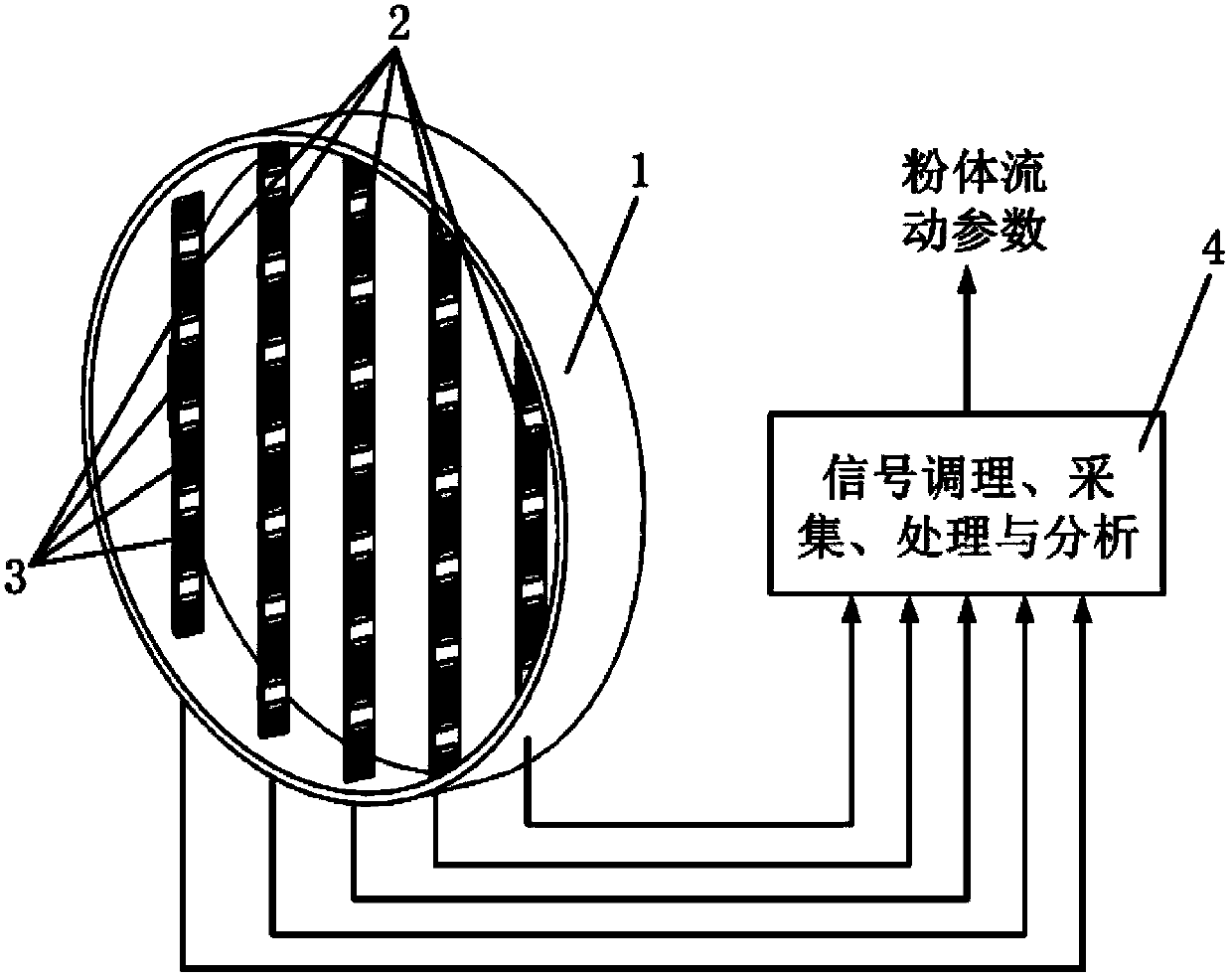

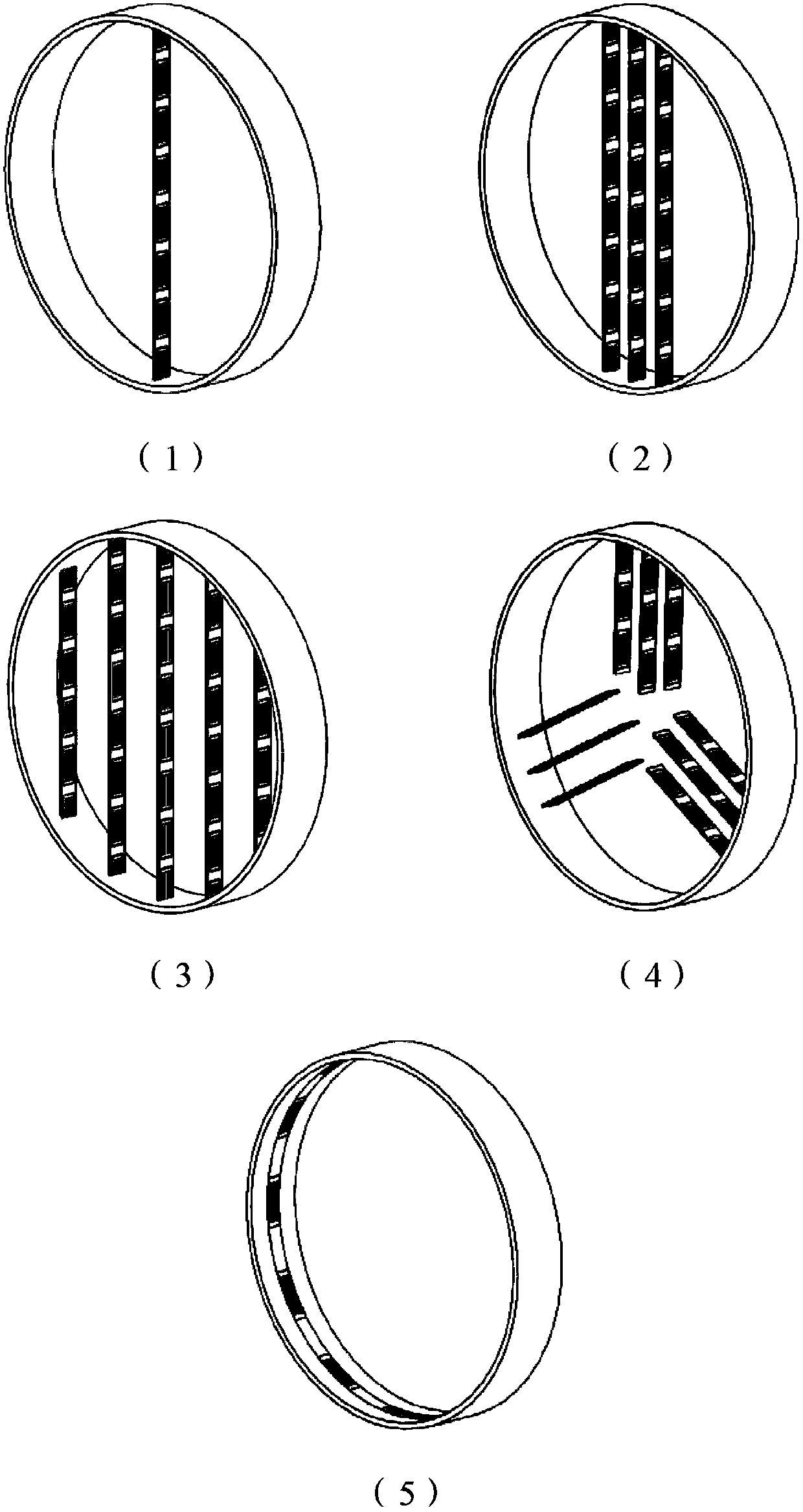

[0016] The invention provides an on-line measurement device and method for powder flow based on an array electrostatic sensor. Below in conjunction with accompanying drawing and embodiment the present invention is described as follows:

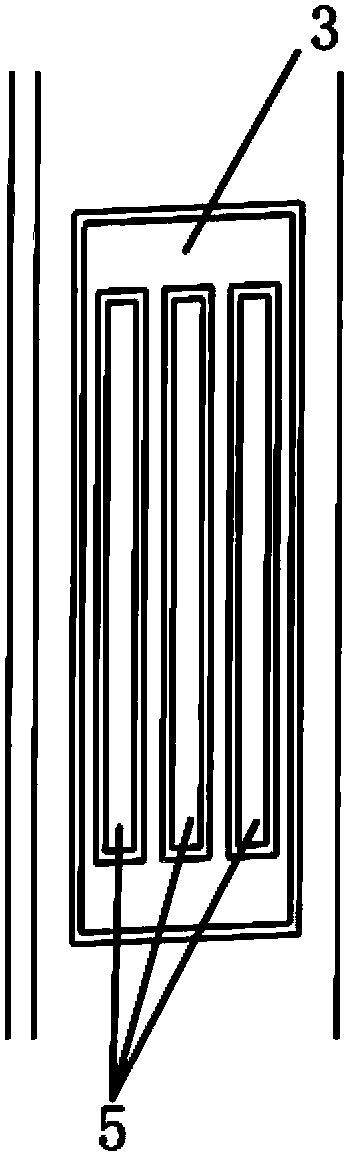

[0017] figure 1 Shown is a schematic diagram of the principle structure of the powder flow measurement device. In the figure, an electrostatic induction probe 2 is inserted into the gas-solid two-phase flow pipeline 1, and the electrostatic induction probe 2 is immersed in the particle flow field; the electrostatic induction probe 2 has a flat structure, and the interior of the electrostatic induction probe 2 is hollow to install a charge amplification circuit board , the output signal of the charge amplification circuit board is connected to the embedded data processing module 4 for signal conditioning, acquisition, processing and analysis; the embedded data processing module 4 outputs powder flow parameter information for research, diagnosi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com