Avalanche photodiode and method for manufacturing the same

An avalanche optoelectronics and manufacturing method technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of carrier movement obstruction, valence band/conduction band energy level discontinuity, poor high-speed response, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

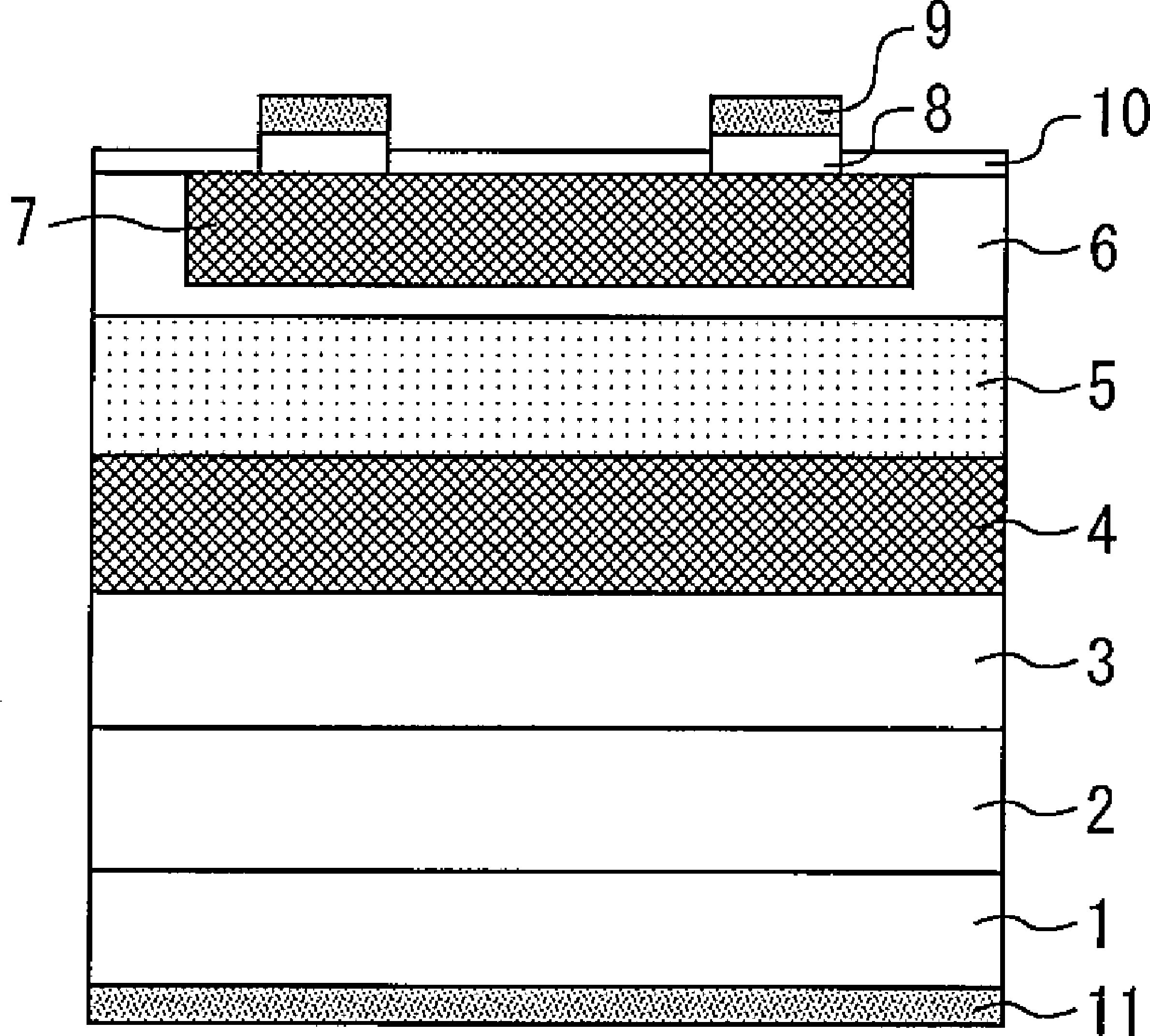

[0033] figure 1 is a cross-sectional view showing the avalanche photodiode according to Embodiment 1 of the present invention. On the n-type InP substrate 1, an n-type AlInAs buffer layer 2, an AlInAs avalanche multiplication layer 3, a p-type AlInAs electric field control layer 4, an undoped light absorbing layer 5 and a window layer 6 are sequentially laminated. Carbon is used as a dopant for the p-type AlInAs electric field control layer 4 .

[0034] The carrier concentration of the n-type AlInAs buffer layer 2 is 5×10 18 cm -3 Hereinafter, the layer thickness is 0.1 to 1 μm. The carrier concentration of AlInAs avalanche multiplication layer 3 is 0.1×10 15 ~8×10 15 cm -3 , the layer thickness is 0.05-0.5 μm. The carrier concentration of the p-type AlInAs electric field control layer 4 is 2×10 17 ~2×10 18 cm -3 , the layer thickness is 0.01-0.2 μm. The layer thickness of the undoped light absorbing layer 5 is 0.5-2.5 μm. The window layer 6 is not doped or doped a...

Embodiment approach 2

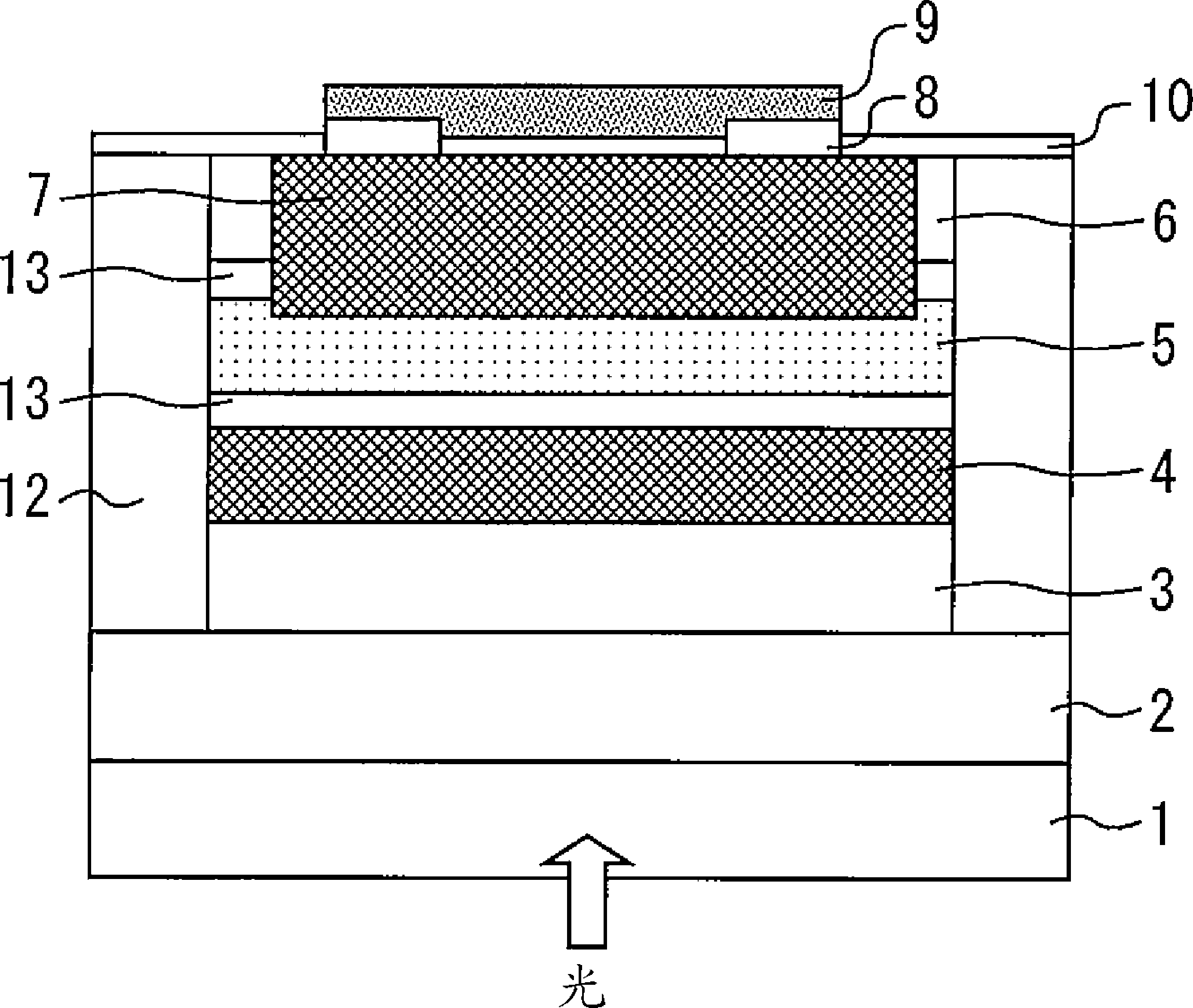

[0052] Figure 5 is a cross-sectional view showing an avalanche photodiode according to Embodiment 2 of the present invention. The semi-insulating buried semiconductor layer 12 is buried in the sides of the AlInAs avalanche multiplication layer 3 , the p-type AlInAs electric field control layer 4 , the undoped light absorbing layer 5 and the window layer 6 . However, it is only necessary that the embedded semiconductor layer 12 is embedded in at least the undoped light absorbing layer 5 . The buried semiconductor layer 12 has a wider band gap than the undoped light absorbing layer 5 .

[0053] The embedded semiconductor layer 12 can prevent the undoped light absorbing layer 5 with a narrow band gap from being exposed, and improve device reliability. Furthermore, since the undoped window layer 6 exists between the p-type region 7 and the buried semiconductor layer 12, leakage current does not increase.

Embodiment approach 3

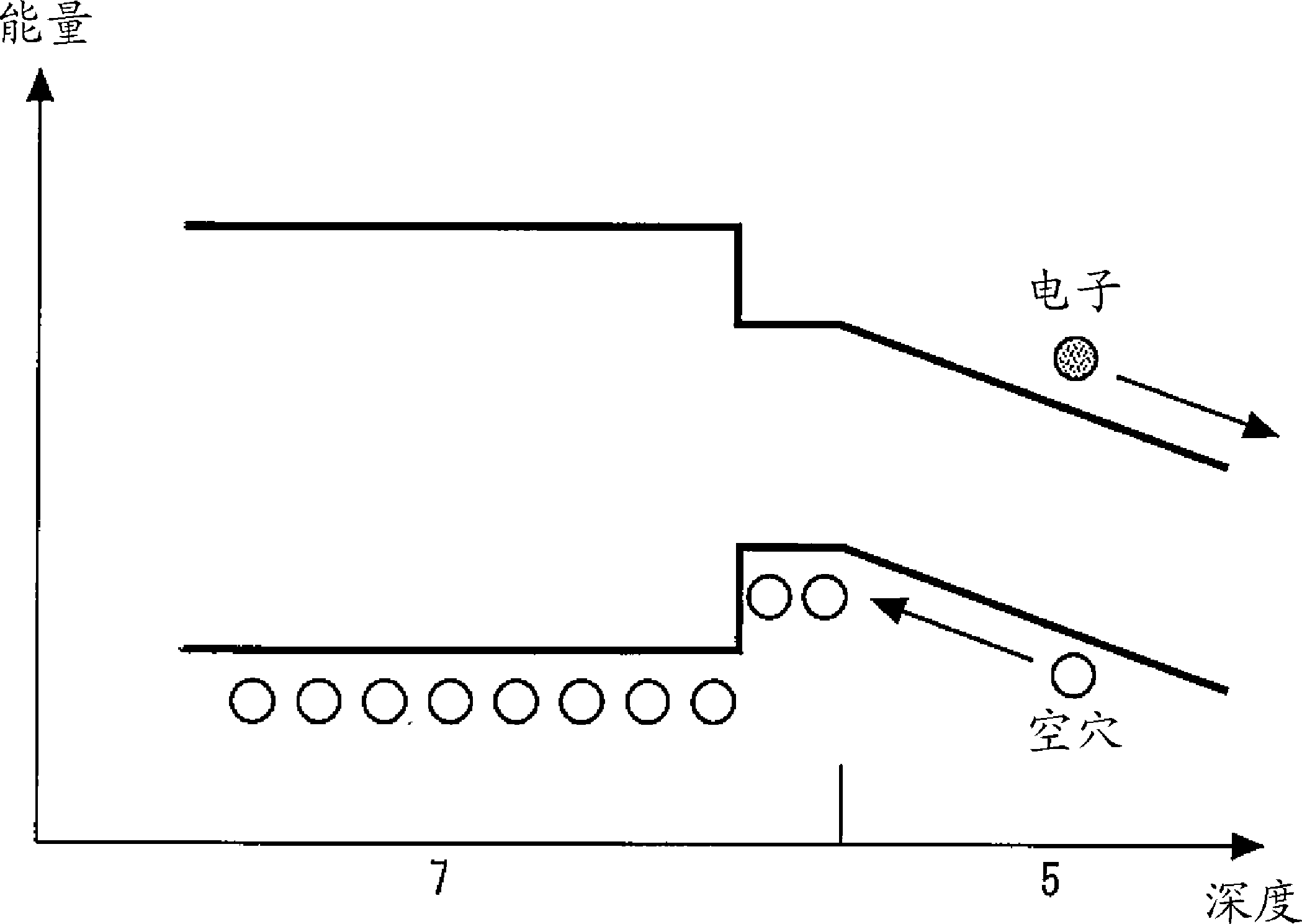

[0055] Figure 6 is a cross-sectional view showing an avalanche photodiode according to Embodiment 3 of the present invention. A graded layer 13 is provided between the undoped light absorbing layer 5 and the adjacent layer. Other structures are the same as those in Embodiment 2. Thereby, the discontinuity between the valence band and the conduction band between the undoped light absorbing layer 5 and the adjacent layer becomes small, and the movement of carriers becomes easy, so that high-speed response can be improved. In addition, although it is preferable that the graded layer 13 is located on both sides of the undoped light-absorbing layer 5, it is effective even if it is located on only one side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com