OLED display drive circuits and techniques

A pixel driving circuit, display panel technology, applied in the direction of circuits, static indicators, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

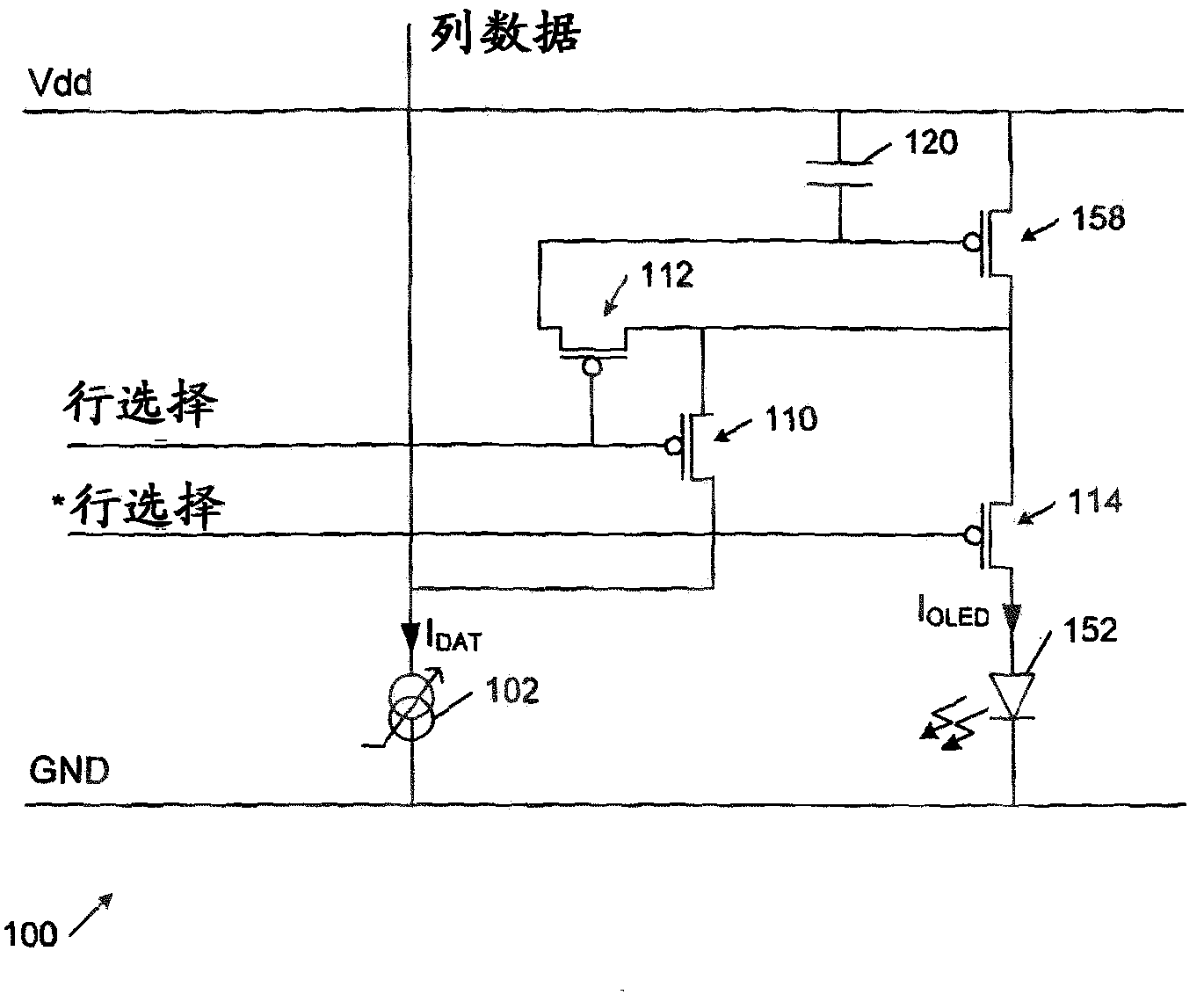

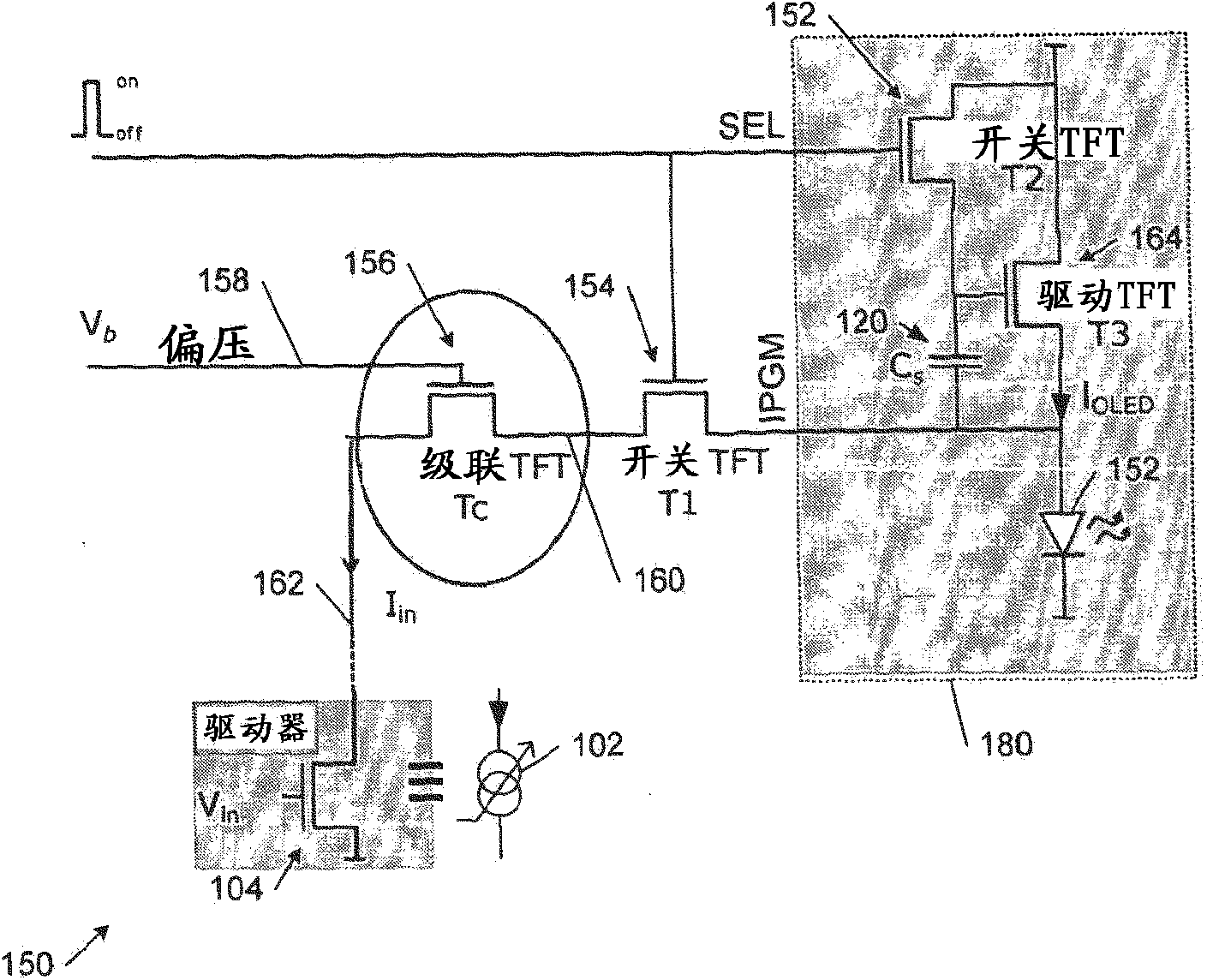

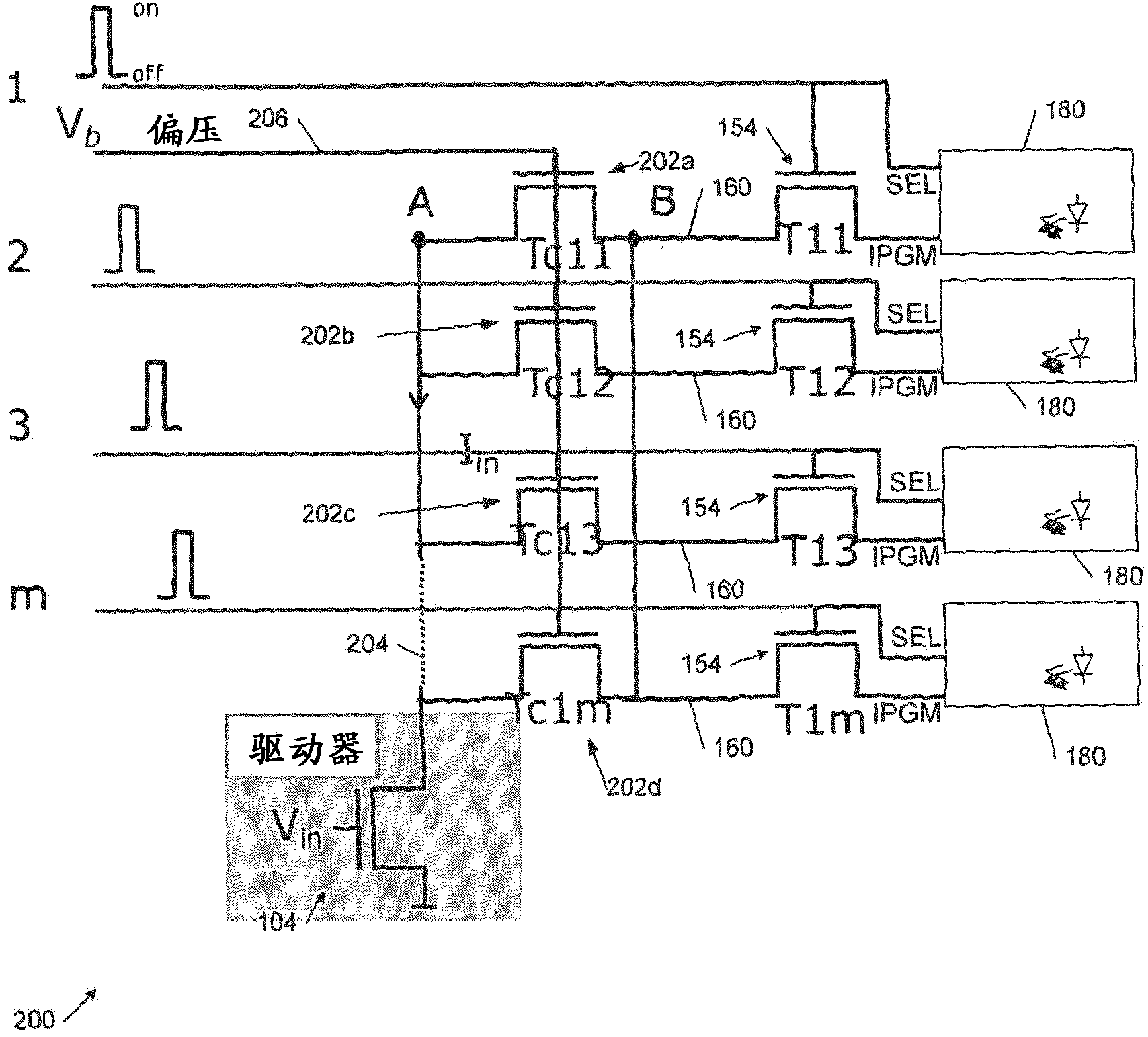

[0031] The two requirements for OLED displays relate to:

[0032] a. Programming / Settling Time - The requirement for brightness programming within a specified programming time that decreases with increasing resolution. If the programming of brightness is not completed within the specified time, this can result in either loss of grayscale information or loss of contrast or both.

[0033] b. Aging (Vt drift) - the requirement to compensate for drift in Vt (and μ). If unsuccessful, this can reduce brightness and / or cause image retention.

[0034] The main schemes for programming pixel circuits can be divided into voltage programming (VP) and current programming (CP). The voltage programming scheme provides fast programming times, and therefore it is suitable for high resolution displays. But such technology requires additional features to compensate for OLED aging (which changes the brightness-voltage characteristics) and voltage drop on the power line.

[0035] The current p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com