Two-stage electrostatic oil mist purifier

A technology of purifiers and oil mist separators, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of poor purification effect and low purification efficiency, achieve high purification efficiency, low operating energy consumption, The effect of saving filter material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

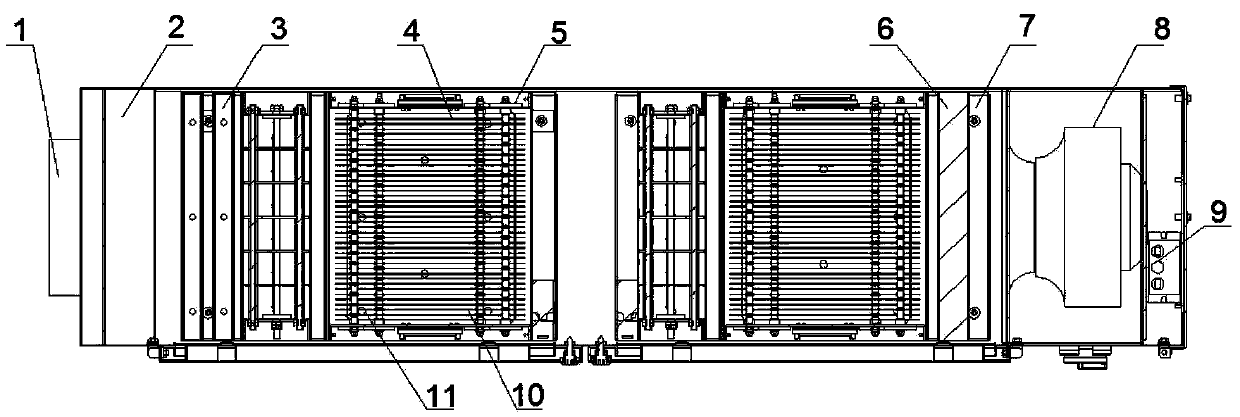

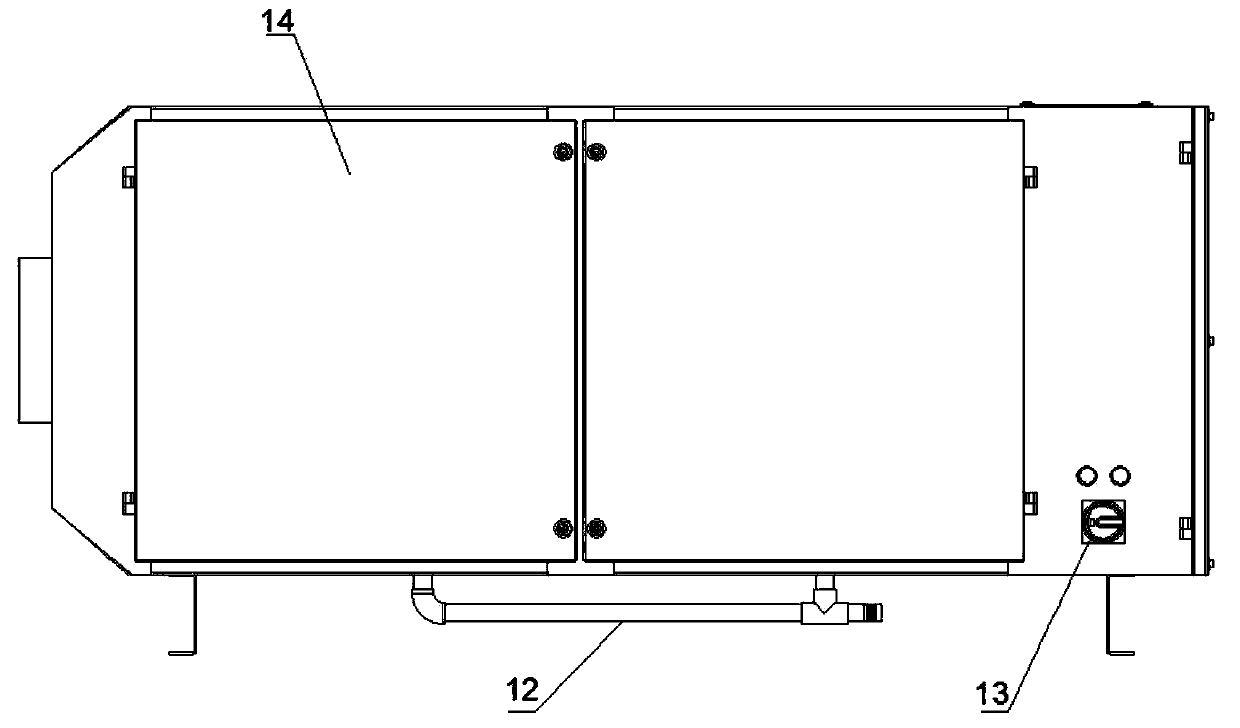

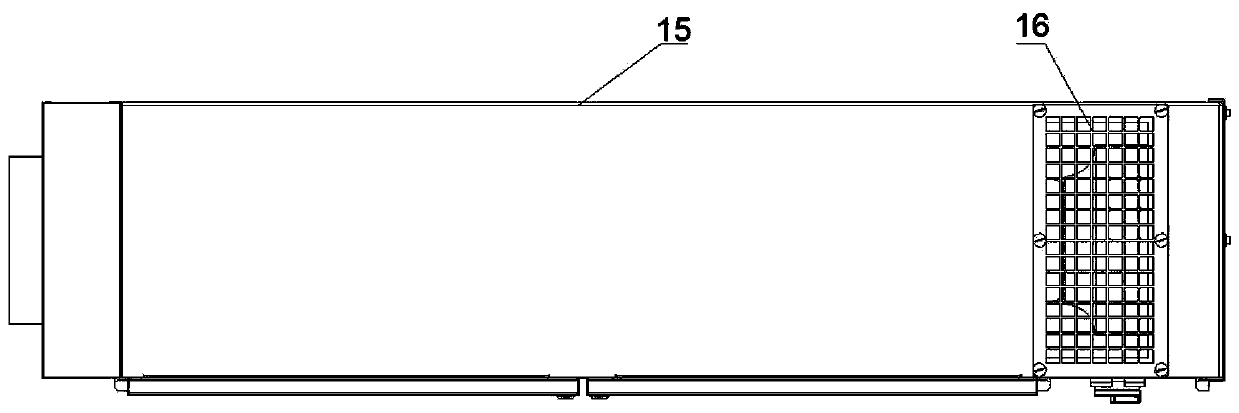

[0011] according to Figure 1~3 The specific structure of the present invention will be described in detail. The two-stage electrostatic oil mist purifier includes a closed casing 15 made of carbon steel provided with an air inlet 1 and an air outlet 16 . In the housing 15, oil mist separator 2, pre-filter 3, electrostatic filter 4, activated carbon filter 6, post-filter 7, and fan 8 are arranged in sequence from the air inlet 1 to the air outlet 16. Fan cavity. The blower fan 8 adopts a backward inclined centrifugal fan, and the impeller blades are made of steel plates, and the blades are subjected to anti-corrosion treatment. Oil mist separator 2, pre-filter 3, electrostatic filter 4 (such as figure 1 As shown, several groups of electrostatic filters 4 connected in series can be set (the present embodiment is two groups) and post filters 7 are provided with slideways, which can be pulled out during replacement to facilitate maintenance. Each filter is sealed between the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com