Single-fan welding fume absorption purifier

A technology of purifier and single blower, which is applied in the direction of chemical instruments and methods, separation of dispersed particles, combined devices, etc. It can solve the problems of large suction, low absorption and purification efficiency, and small resistance, so as to achieve small equipment resistance, high efficiency, The effect that is not easy to be dirty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

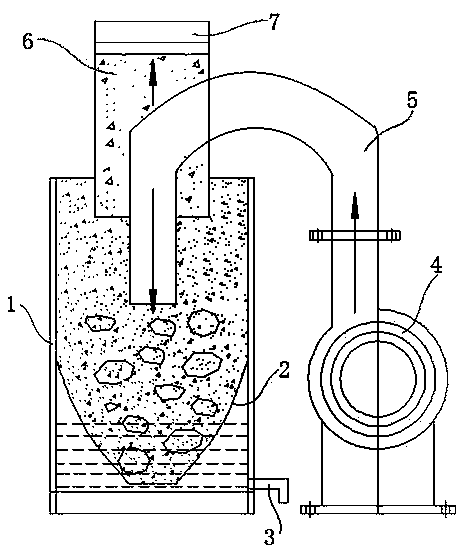

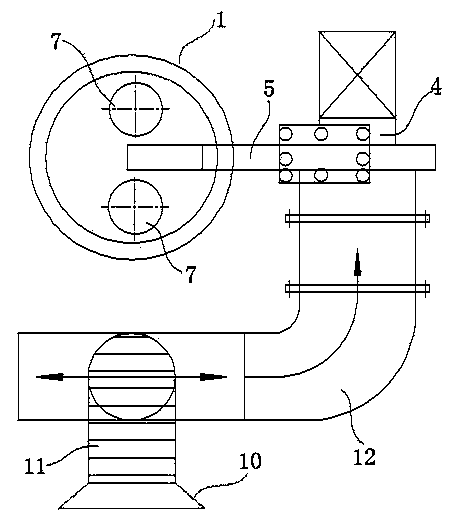

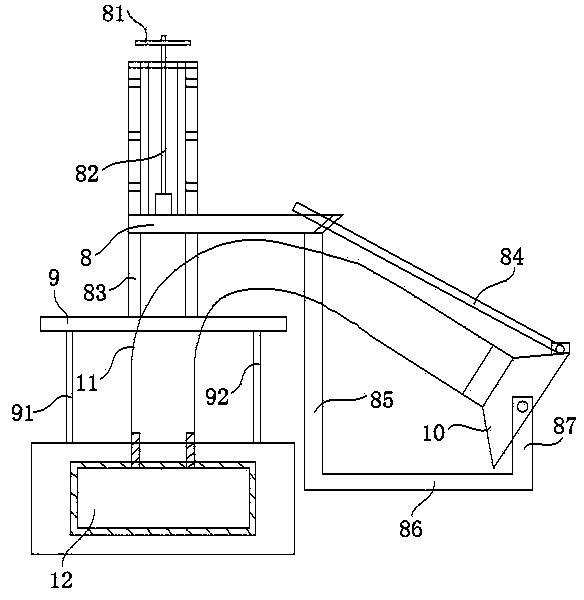

[0028] like figure 1 As shown, the welding fume purification mechanism in this embodiment is used to purify the welding fumes absorbed by the smoking mechanism. A drain valve 3 is provided at the bottom of the clean room 1 described above. The recoiler 2 is located inside the clean room 1, and the bottom of the recoiler 2 is connected to the clean room 1. The clean room 1 is equipped with a purification liquid, and the above-mentioned fan 4 transports the welding fumes to the clean room inside the recoiler 2. In the liquid, the recoiler 2 is an inverted cone structure, the upper opening of the recoiler 2 is larger than the lower opening, and the recoiler 2 is provided with steel wool and sponge blocks, specifically in this embodiment: clean room The internal diameter of 1 is 450mm, the height of clean room 1 is 500mm, the upper opening diameter of recoiler 2 is 440mm, the lower opening diameter of recoiler 2 is 180mm, the height of recoiler 2 is 130mm, recoiler 2 There is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com