Driving device with double variable frequency motors of rubber roll rice huller

A variable frequency motor and motor drive technology, which is applied to control multiple AC motors, electrical components, grain processing, etc., can solve problems such as gear box oil leakage noise, reduce vibration and noise, reduce machine costs, and reduce energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings.

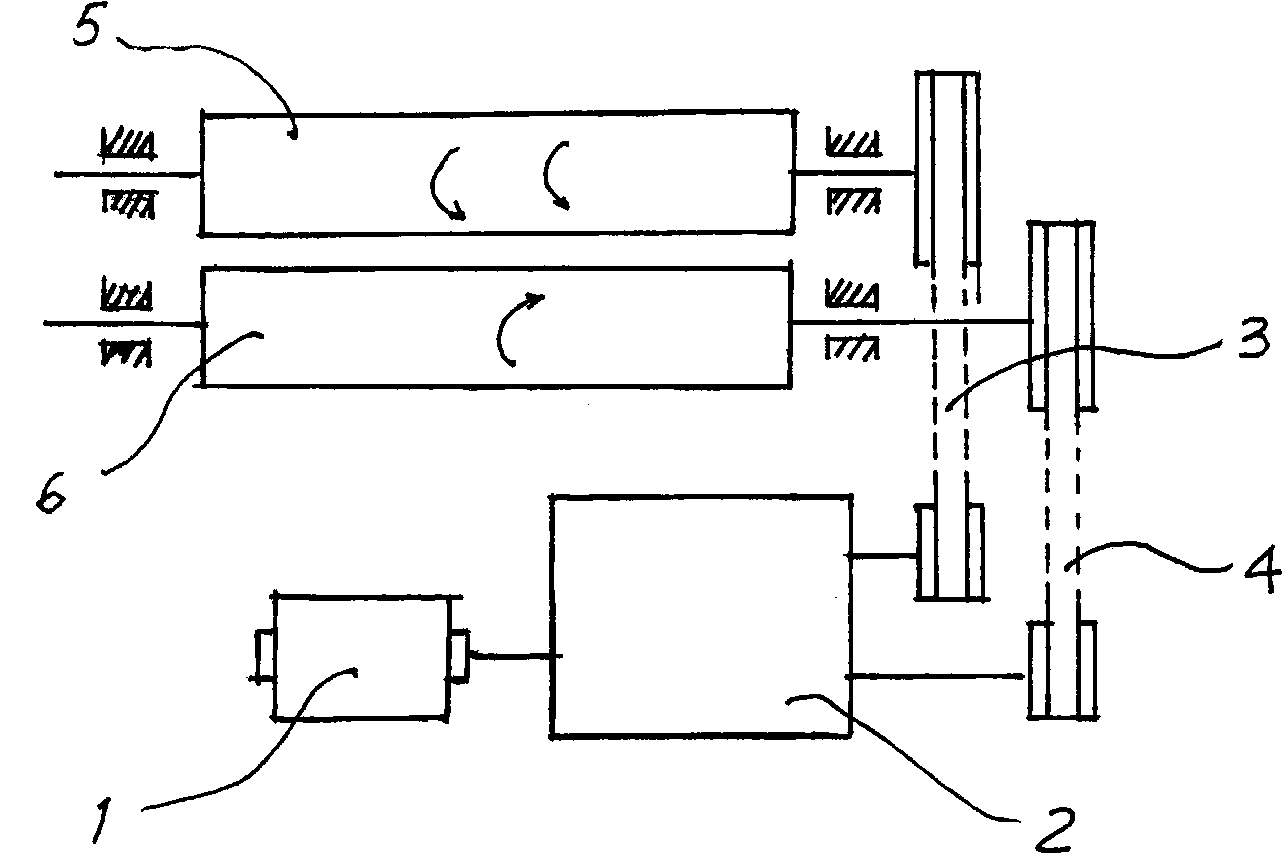

[0017] figure 1 It is a prior art, and it is a structural schematic diagram of a rice huller gear box and a double transmission belt driving device, and its working principle has been described in the background technology.

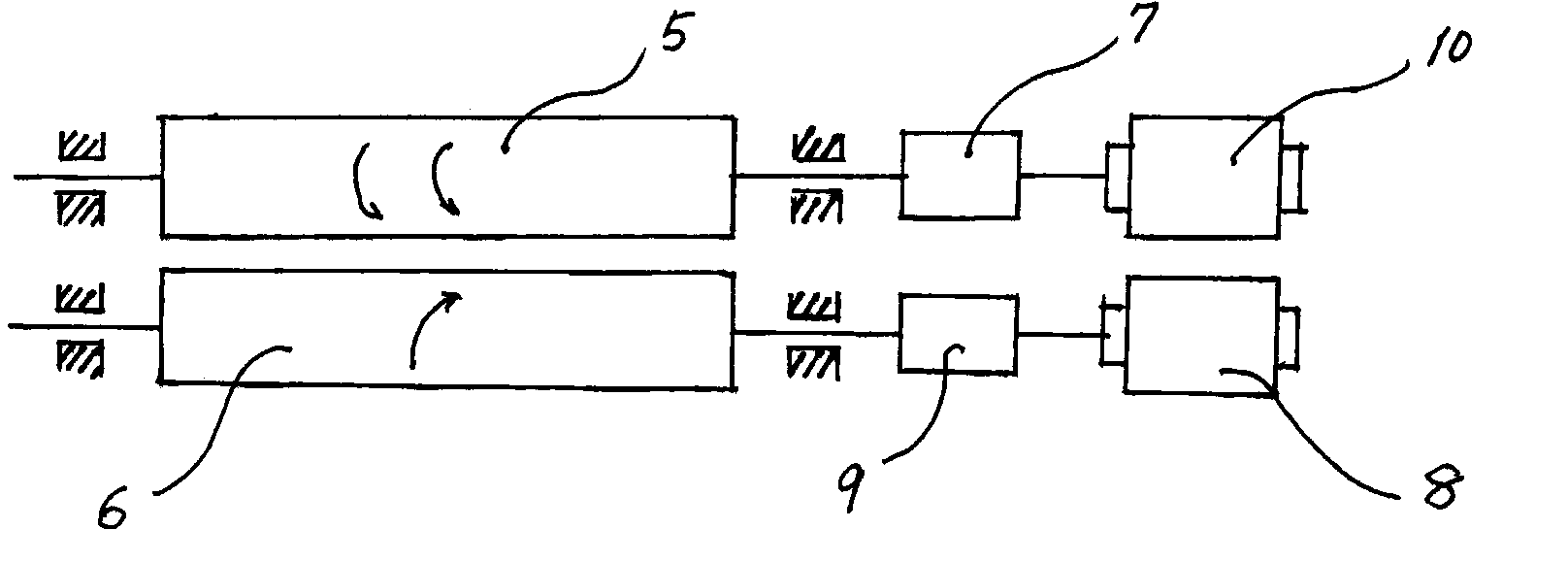

[0018] figure 2 It is a schematic diagram of the structure of the double ordinary motor transmission device (or claiming the driving device) of the rice huller, and its working principle has been described in the background technology.

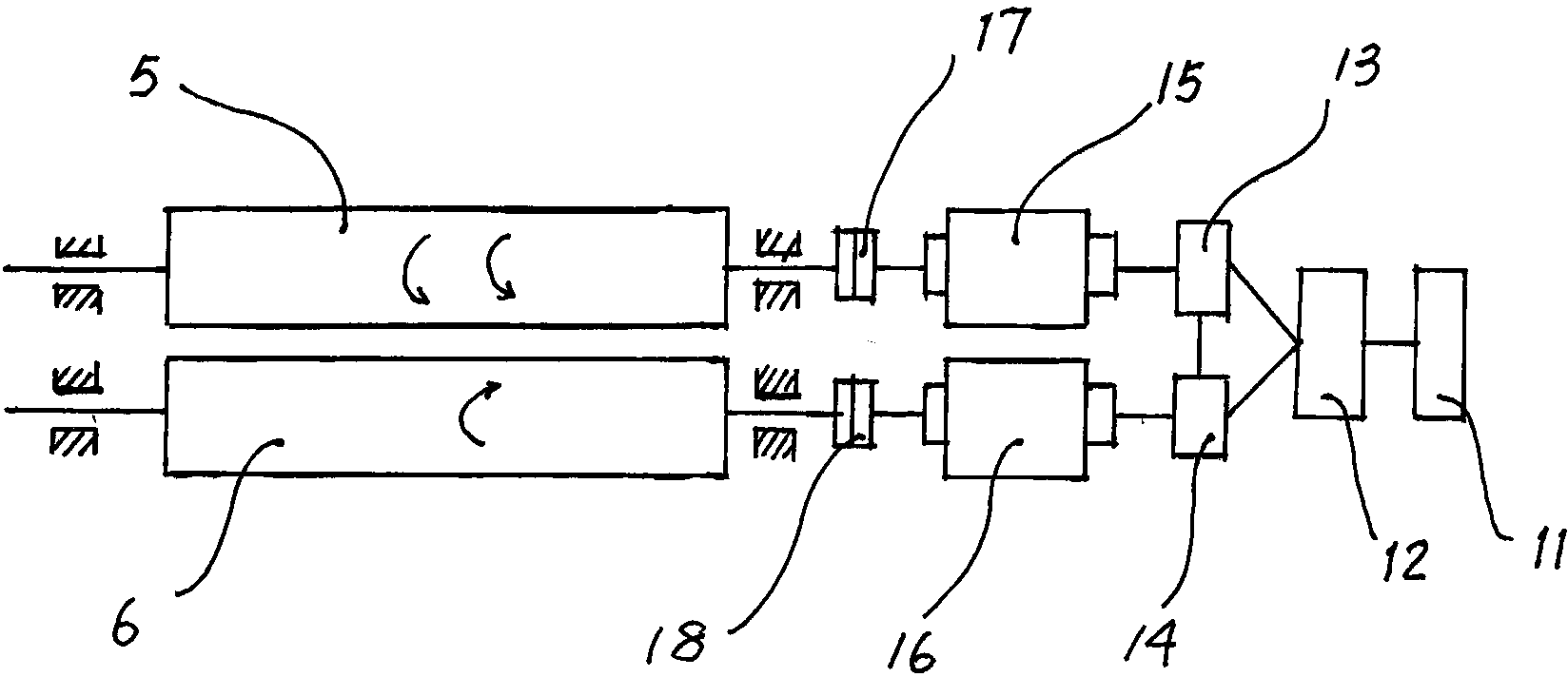

[0019] image 3 It is the structural schematic diagram of the double frequency conversion motor driving device of the rubber roller huller of the present invention. exist image 3 Among them, there are fast roller 5, fast roller coupling 17, fast roller frequency conversion motor 15, fast roller frequency converter 13; slow roller 6, slow roller coupling 18, slow roller frequency conversion motor 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com