Method for clearing material lumps on cylinder wall of cylinder warehouse

A cleaning method and the technology of the cylinder storehouse, which is applied in the field of cleaning the clotted blocks on the cylinder wall of the cylinder storehouse, can solve the problems of low efficiency and poor safety, and achieve the effects of reducing production costs, low use costs, and eliminating safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

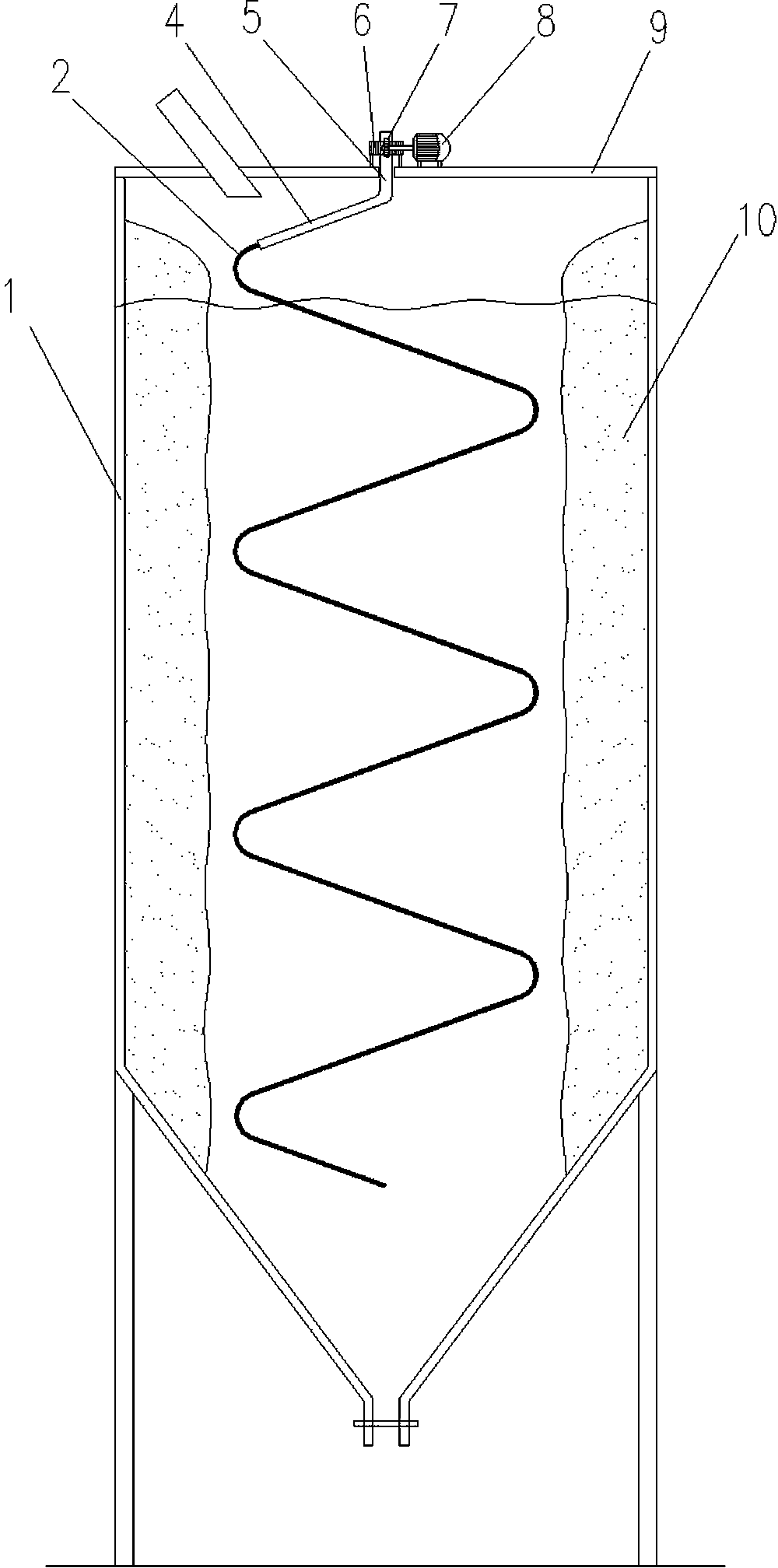

[0013] Such as figure 1 As shown, a method for cleaning the agglomerated material on the cylinder wall of the cylinder warehouse provided by the present invention includes a cylinder warehouse 1, the inner wall of the cylinder warehouse 1 is bonded with a clot 10, and the top cover 9 of the cylinder warehouse 1 is provided with a frequency modulation The motor 8 and its connecting gear 7; the center of the top cover 9 of the cylinder warehouse 1 is connected with a rotating arm, which is composed of a vertical rotating shaft 5 and a rotating arm 4 connected with a certain curvature at its lower end, and the driving gear 6 and gear 7 are connected on the vertical rotating shaft 5 Mesh transmission; a steel wire rope 2 is connected to the end of the rotating arm 4 .

[0014] The frequency modulation motor 8 drives the rotating arm to rotate, so that the rotating arm 4 ends drive the steel wire rope 2 to perform spiral rotation, and the helical rotation force of the steel rope hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com