High active concrete admixture

A concrete and admixture technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problem of weakening the activity advantages of high-calcium fly ash, difficulty in increasing the content of high-calcium fly ash, and product Poor performance stability and other problems, to achieve the effect of eliminating hidden dangers of stability, significant economic and social benefits, and high hydration activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

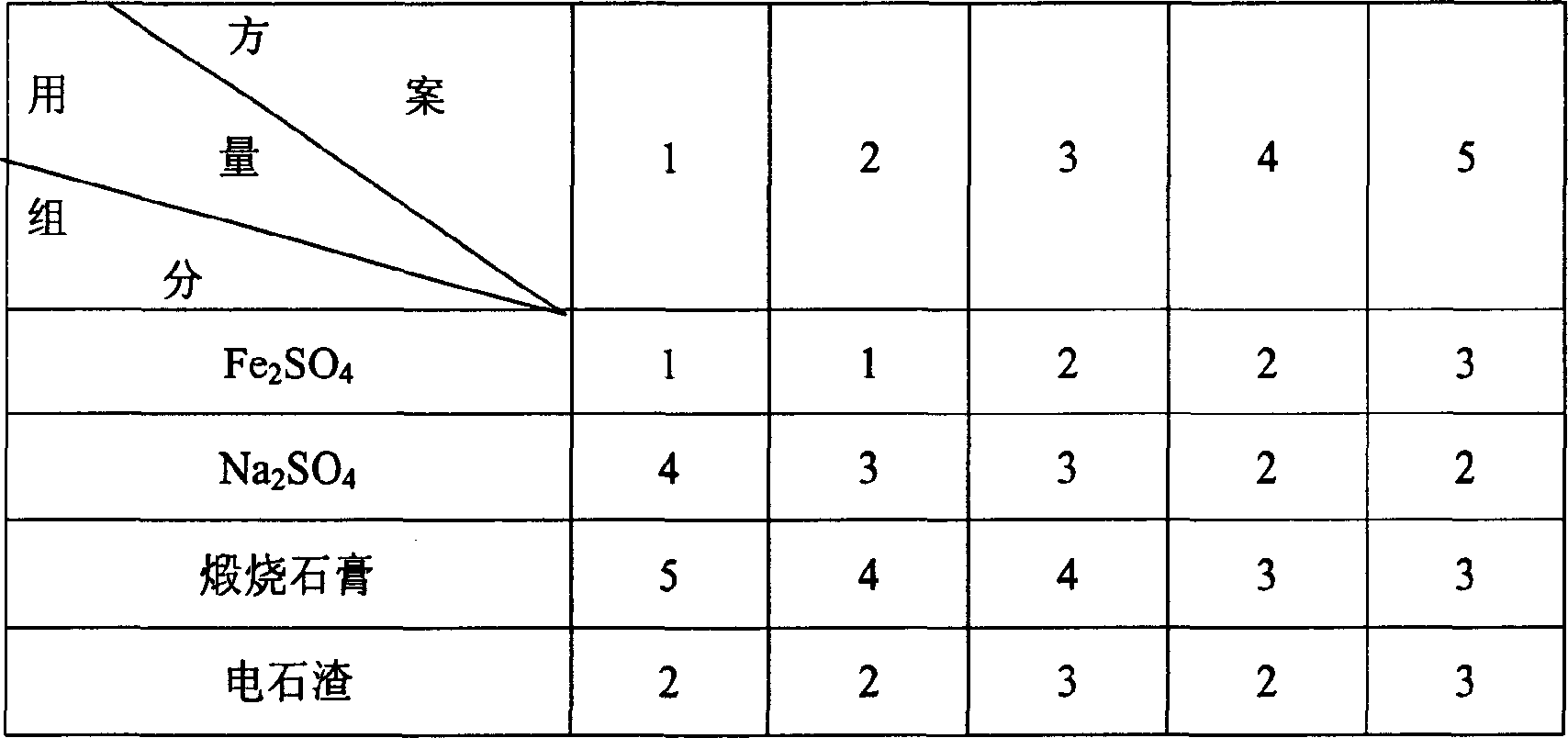

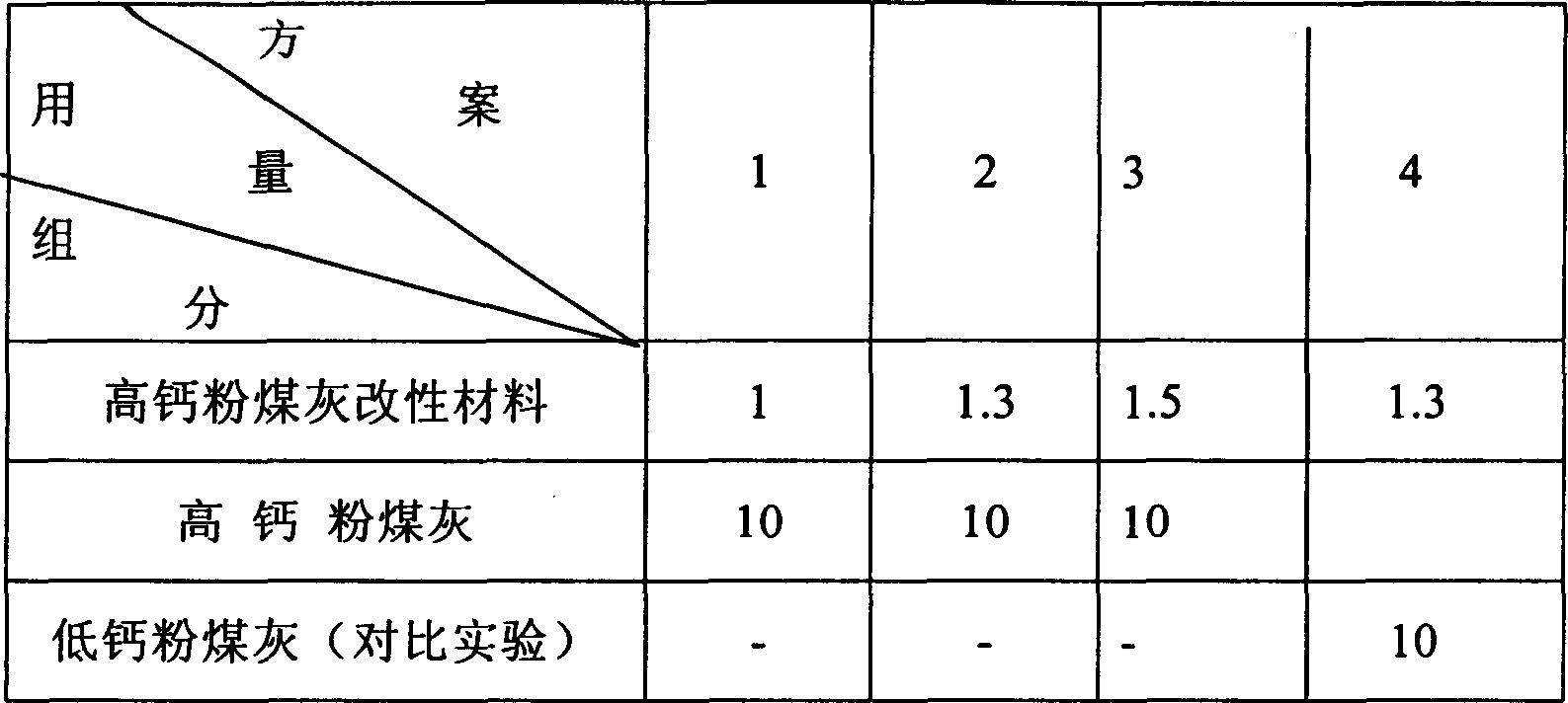

[0024] The preparation method of highly active concrete admixture, 1, mix the raw material ratio by table 1 and prepare high-calcium fly ash modified material:

[0025] Table 1 Formula of high calcium fly ash modified material (weight ratio, unit: part)

[0026]

[0027] High-calcium fly ash is the Blaine specific surface area of 300-600m2 obtained by electric dust collection in power plants that use cyclone boilers to burn lignite and sub-bituminous coal or power plants that use calcium-increasing combustion technology. 2 / kg, the coal ash whose weight content of CaO is 10%-45%, and the weight content of free CaO is 3%-10%.

[0028] Calcined gypsum is obtained by calcining natural gypsum, chemical gypsum or a mixture of natural gypsum and chemical gypsum at a temperature of 750°C-850°C. When natural gypsum and chemical gypsum are mixed, the ratio of the two is arbitrary.

[0029] Carbide slag is the industrial waste from the production of polyvinyl chloride...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com