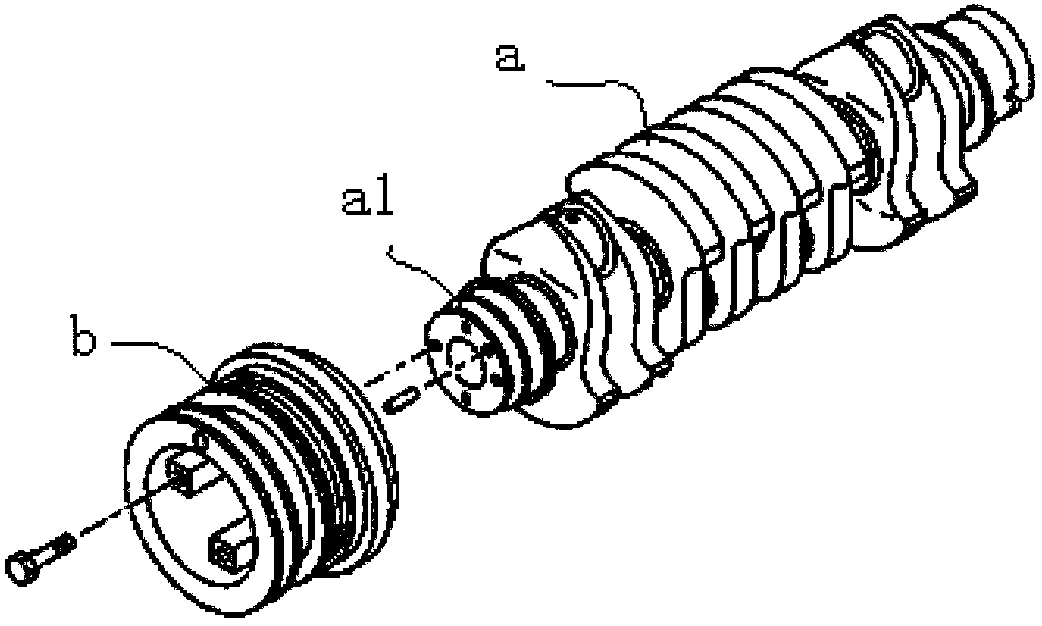

Belt wheel press assembling device and press assembling method

A press-fitting device and pulley technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor intensity, easy fatigue, low production efficiency, etc., and achieve high operating efficiency, simple device structure, and method easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

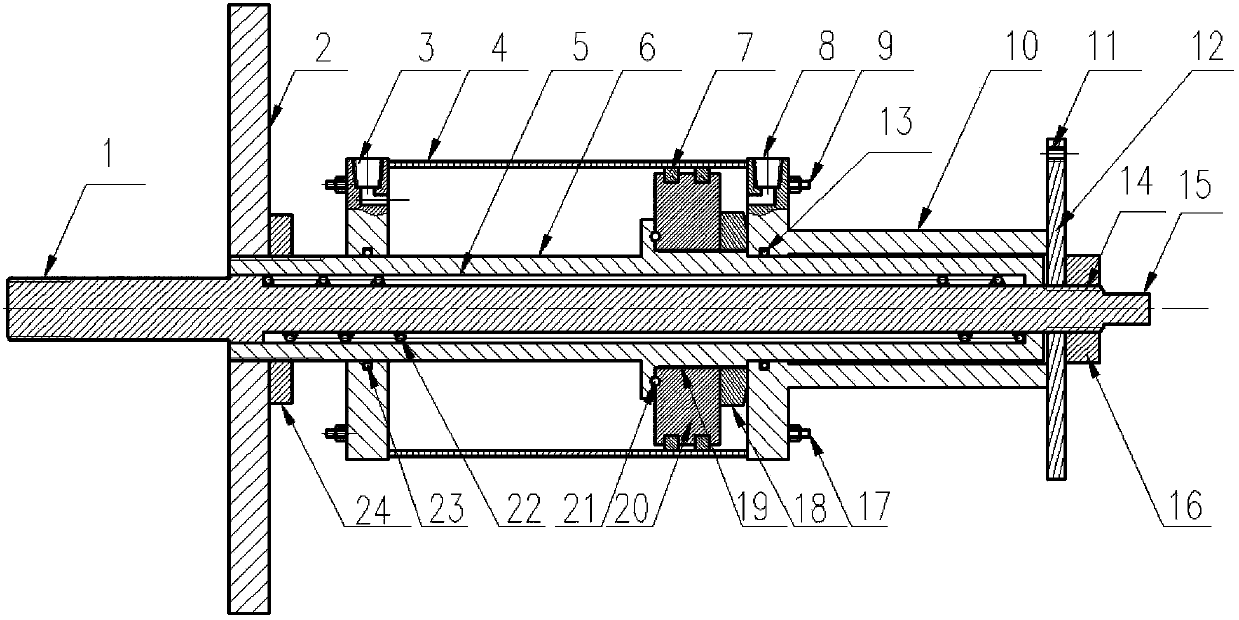

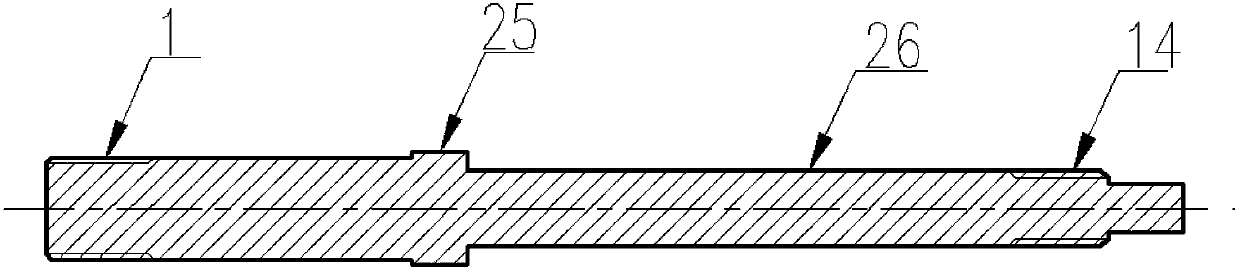

[0026] Such as figure 2 As shown, first introduce the structure and working principle of the belt pulley press-fitting device. The device includes a screw rod 15, a piston rod 6, a pressure plate 2 and a telescopic drive part; the piston rod 6 is sleeve-shaped, sleeved on the screw rod 15 and Move on the screw rod 15 under the action of the telescopic driving part; the pressure plate 2 is fixed on one end of the piston rod 6; The external thread 1 matched with the thread hole on the end surface of the crankshaft head where the pulley is installed, the telescopic drive part has a fixed end and a telescopic end, the fixed end is in contact with the end of the screw rod 15 away from the pressure plate 2, that is, the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com