Production method of engineering control panel cabinet and production line for engineering control panel cabinet

A production line and production method technology, applied in manufacturing tools, metal processing equipment, assembly machines, etc., can solve the problems of low production efficiency of engineering control panel cabinets, backward overall manufacturing technology, and small operating space, and achieve easy installation and installation. The effect of open space and improved assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

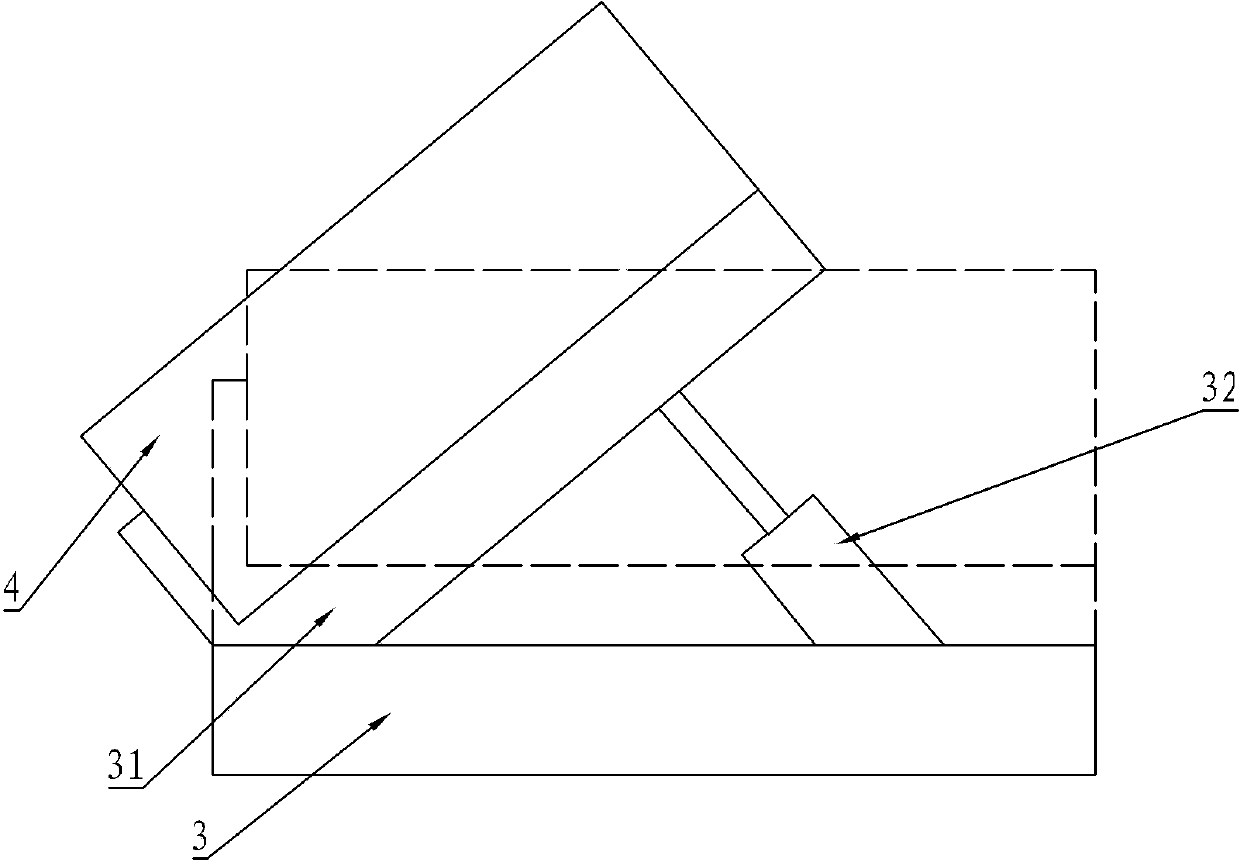

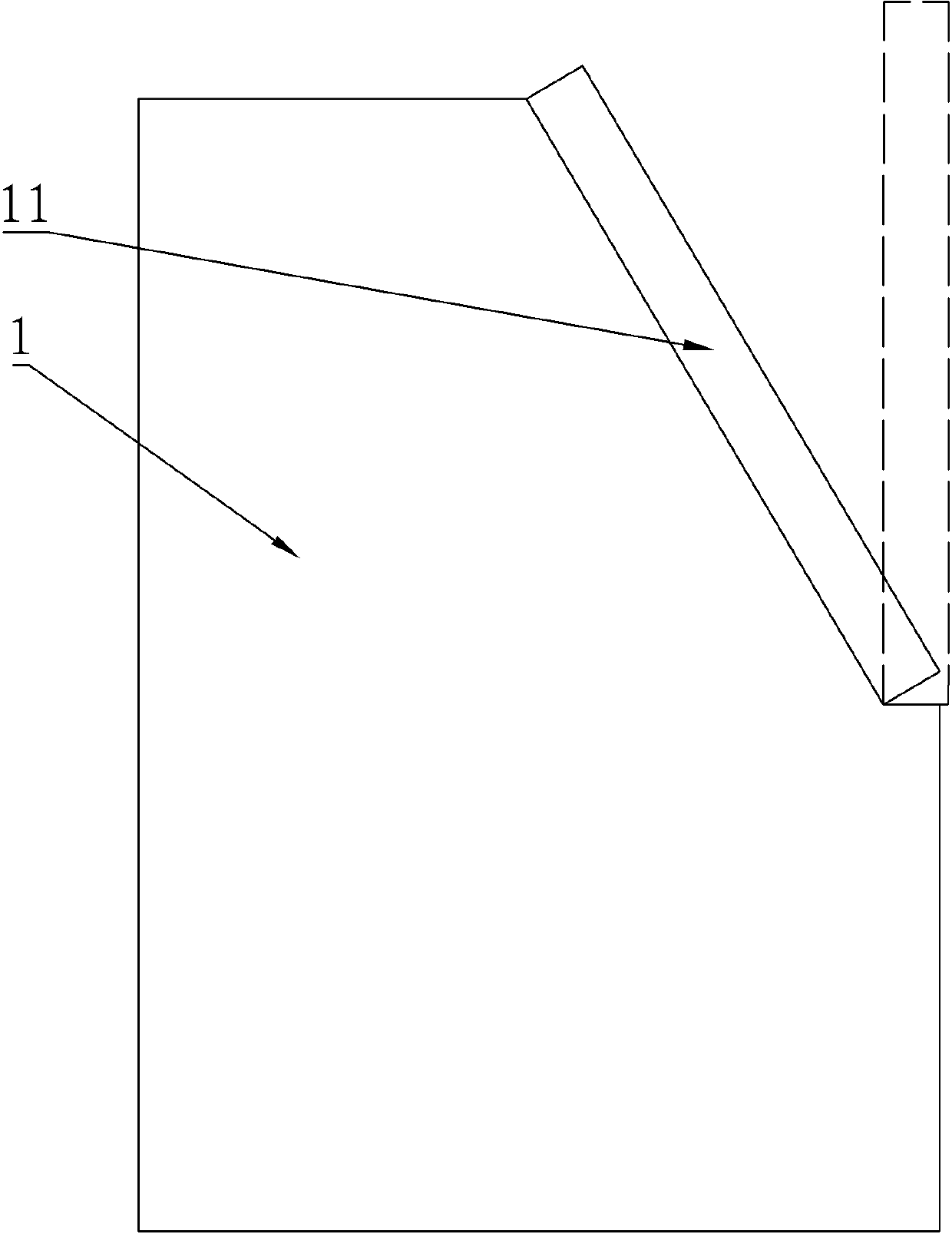

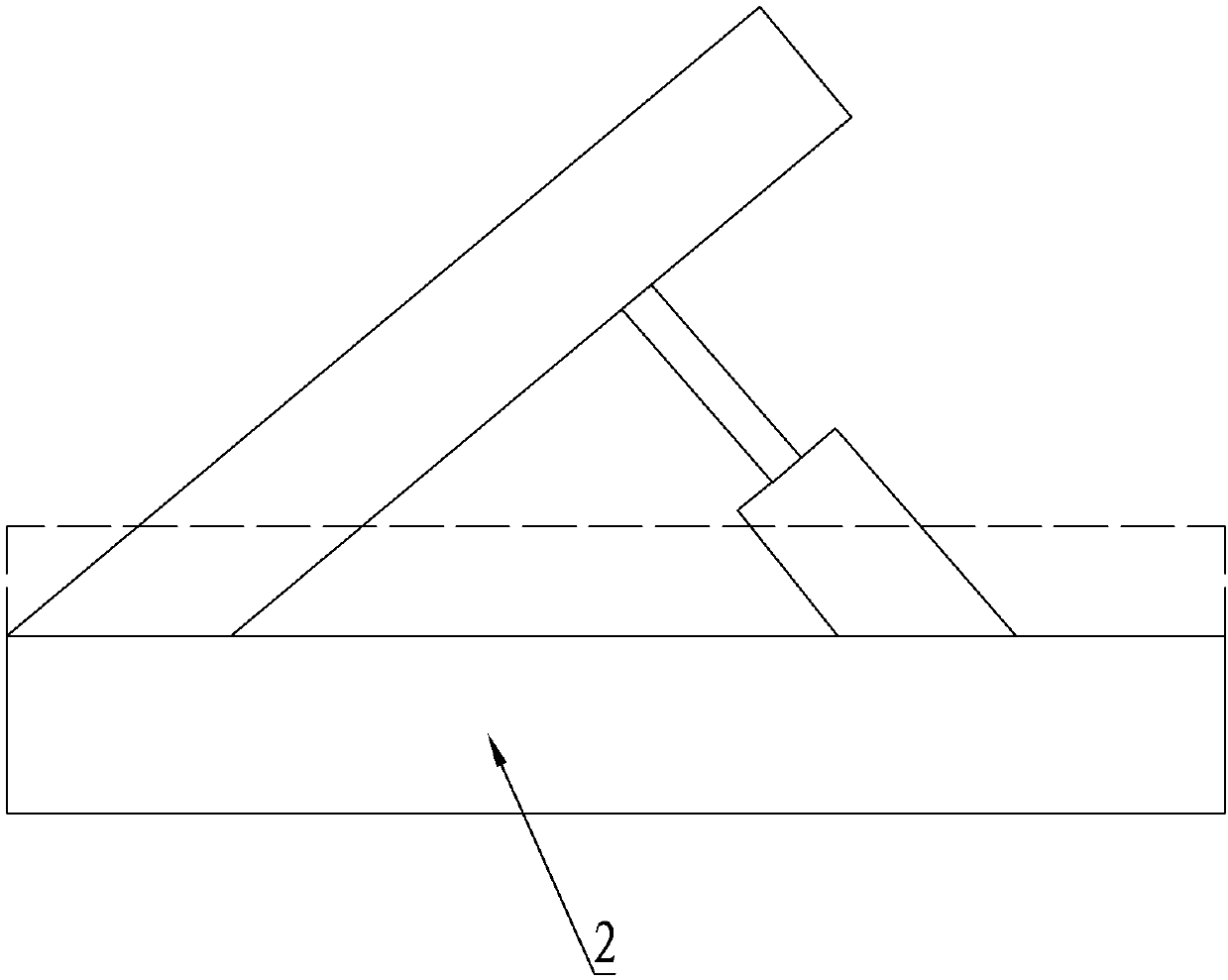

[0021] The embodiment of the production method of engineering control screen cabinet of the present invention: as Figure 1 to Figure 3 As shown, the production method includes the following steps. Step 1, the backboard in the erected state is transferred to the installation device 1 by the transfer trolley, and the backboard is installed in the erected state on the installation device 1. The angle between the surface and the horizontal plane is an acute angle, so as to install electrical components on the mounting surface of the backplane; step 2, lay the backplane in the erected state on the leveling device 2, and level it on the assembly device 3 Place the cabinet body 4 so that the backboard installed with electrical components is laid flat and loaded into the cabinet body 4 by a transfer crane, and the backplane is fixed on the cabinet body 4; step 3, the backplane installed on the assembly device 3 Board, and the cabinet body 4 that puts flat is erected, and the cabinet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com