Integral monitoring system for tower crane

A tower crane and monitoring system technology, applied in cranes, load hanging components, transportation and packaging, etc., can solve problems such as the limited field of vision of tower crane drivers, and the inability of tower crane drivers to know the overall situation of the tower crane at any time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

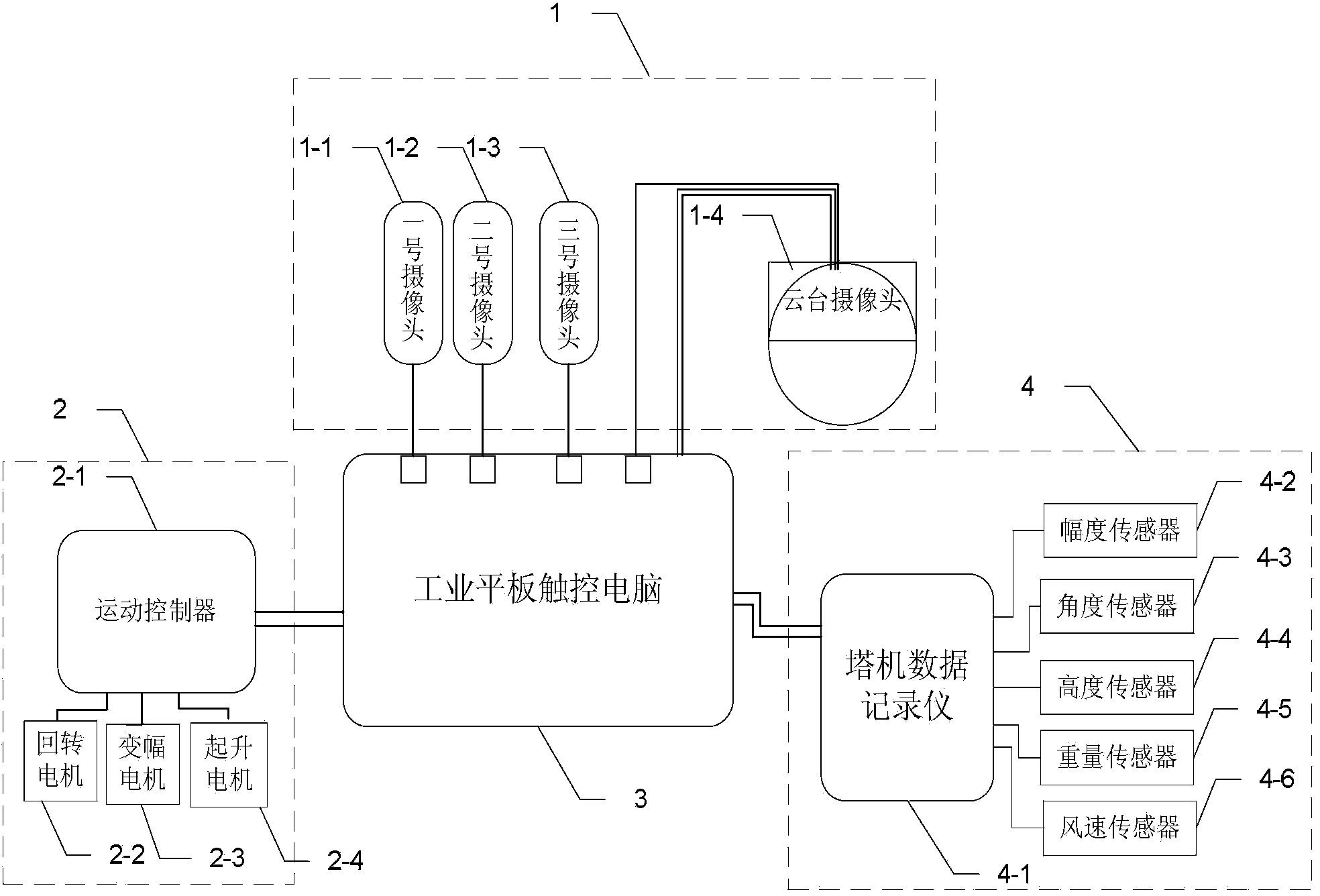

[0020] Specific implementation mode 1. Combination figure 1 Describe this embodiment, the tower crane integrated monitoring system described in this embodiment, the system includes a video monitoring subsystem 1, a motion monitoring subsystem 2, an industrial tablet touch computer 3 and a data recording subsystem 4;

[0021] The video surveillance subsystem 1 includes No. 1 camera 1-1, No. 2 camera 1-2, No. 3 camera 1-3 and PTZ camera 1-4;

[0022] The motion monitoring subsystem 2 includes a motion controller 2-1, a rotary motor 2-2, a luffing motor 2-3 and a lifting motor 2-4;

[0023] The data recording subsystem 4 includes a tower crane data recorder 4-1, an amplitude sensor 4-2, an angle sensor 4-3, a height sensor 4-4, a weight sensor 4-5 and a wind speed sensor 4-6;

[0024] The video signal output terminals of No. 1 camera 1-1, No. 2 camera 1-2, No. 3 camera 1-3 and PTZ camera 1-4 are sequentially connected to the No. 1 input port of the video capture card of the indu...

specific Embodiment approach 2

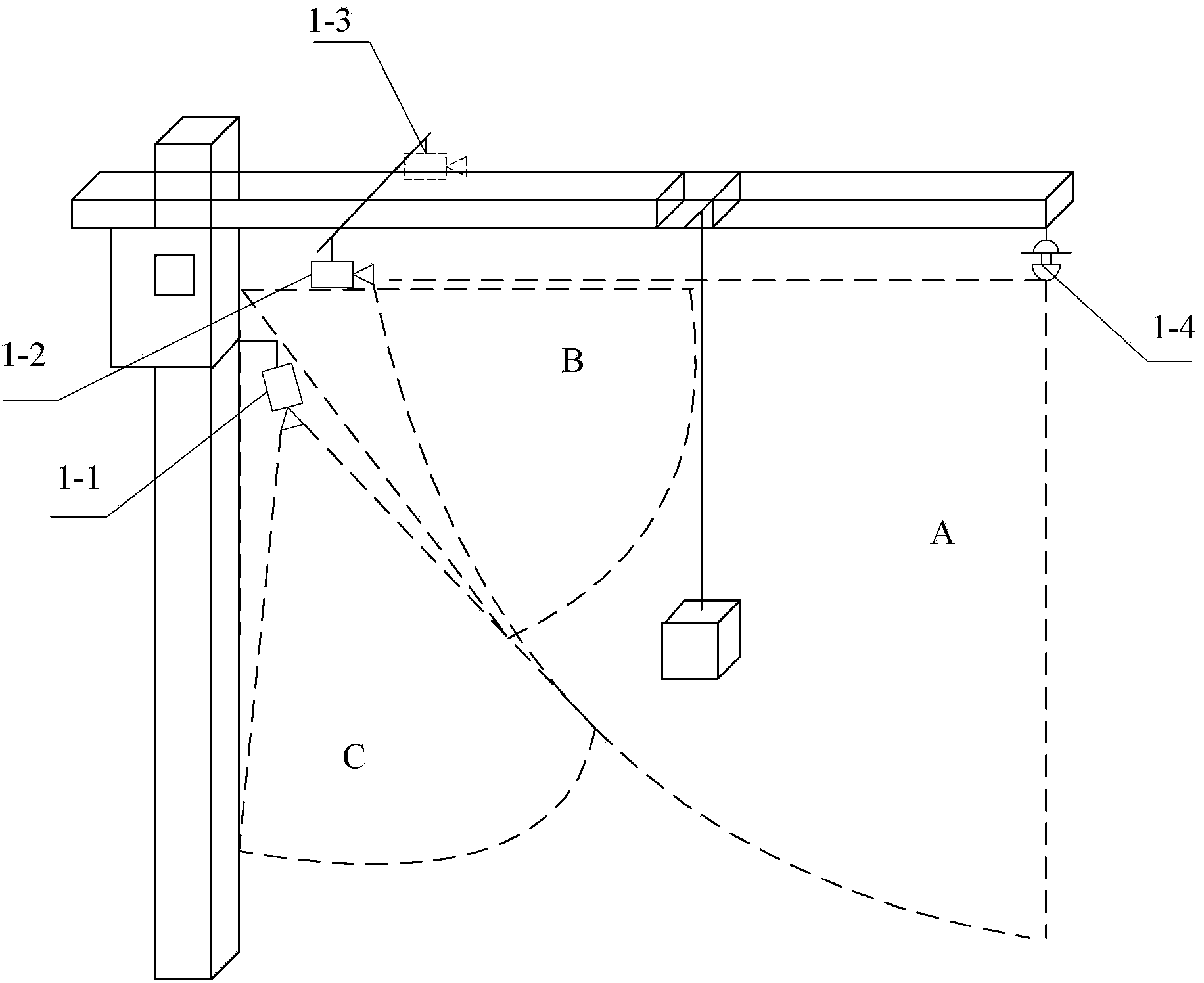

[0032] Specific embodiment two, combine figure 2 This embodiment is described. This embodiment is a further description of the tower crane integrated monitoring system described in Embodiment 1. The No. 1 camera 1-1 is fixedly installed directly below the cockpit of the tower crane, and the No. 1 camera 1-1 The angle between the axis center of 1 and the vertical direction is 30°; No. 2 camera 1-2 and No. 3 camera 1-3 are respectively installed on the left and right sides of the tower arm through the camera bracket, and the direction of the camera is the same as that of the tower arm. The included angles between the axes of camera 1-2 and camera 1-3 and the upper surface of the tower arm are 30°, and the angles between the axes of camera 1-2 and camera 3 and the side of the tower arm are The angles are all 30°, the direction of the camera is the same as that of the tower arm, and the pan / tilt cameras 1-4 are fixedly installed directly below the tower arm.

[0033] The install...

specific Embodiment approach 3

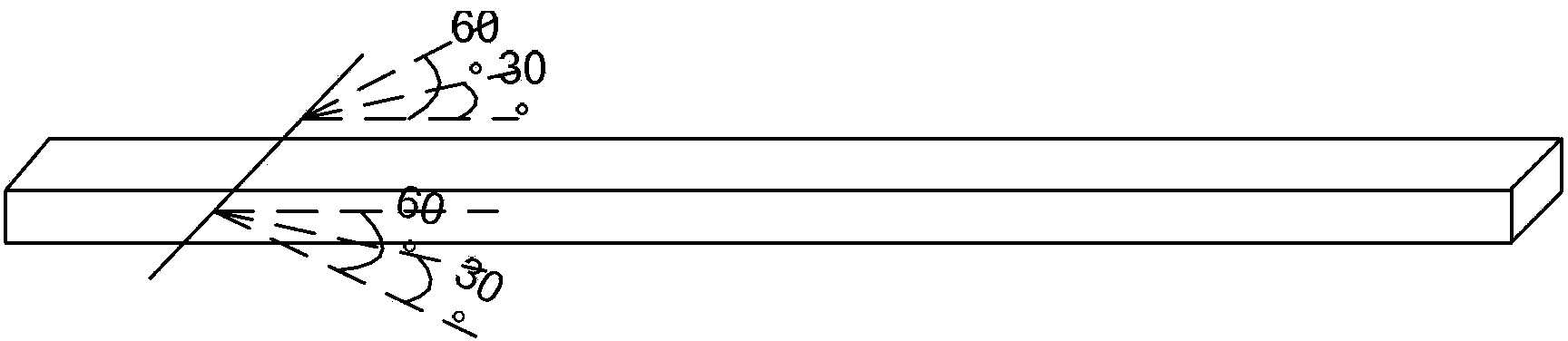

[0034] Specific embodiment three, combine image 3 This embodiment is described. This embodiment is a further description of the tower crane integrated monitoring system described in the second specific embodiment. The second camera 1-2 and the third camera 1-3 both use a viewing angle range of 60°. camera.

[0035] The No. 2 camera and No. 3 camera can respectively expand the field of view of 60° left and right on the horizontal plane of the tower arm, such as image 3 As shown, it can effectively prevent the tower crane from colliding with the building during the slewing motion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com