Waterproof adhesive material for cement-based rigid interface

A bonding material and cement-based technology, which is applied in the field of cement-based rigid interface waterproof bonding materials, can solve the problems of large amount of waterproof coating, affecting building safety, and high cost, so as to improve chemical corrosion resistance and durability, and improve coating The effect of brushing and saving the cost of painting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

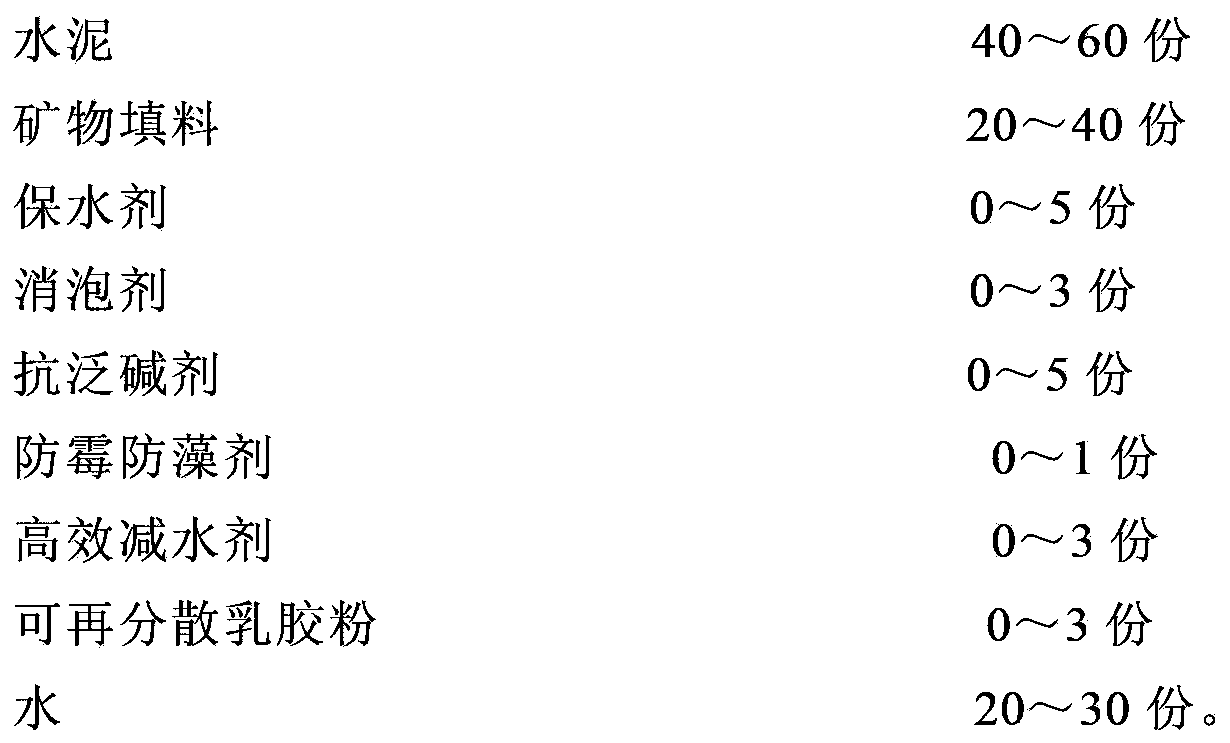

[0022] 1. Based on the above range, in the first embodiment provided by the present invention, the specific parts by weight of each component are as follows:

[0023]

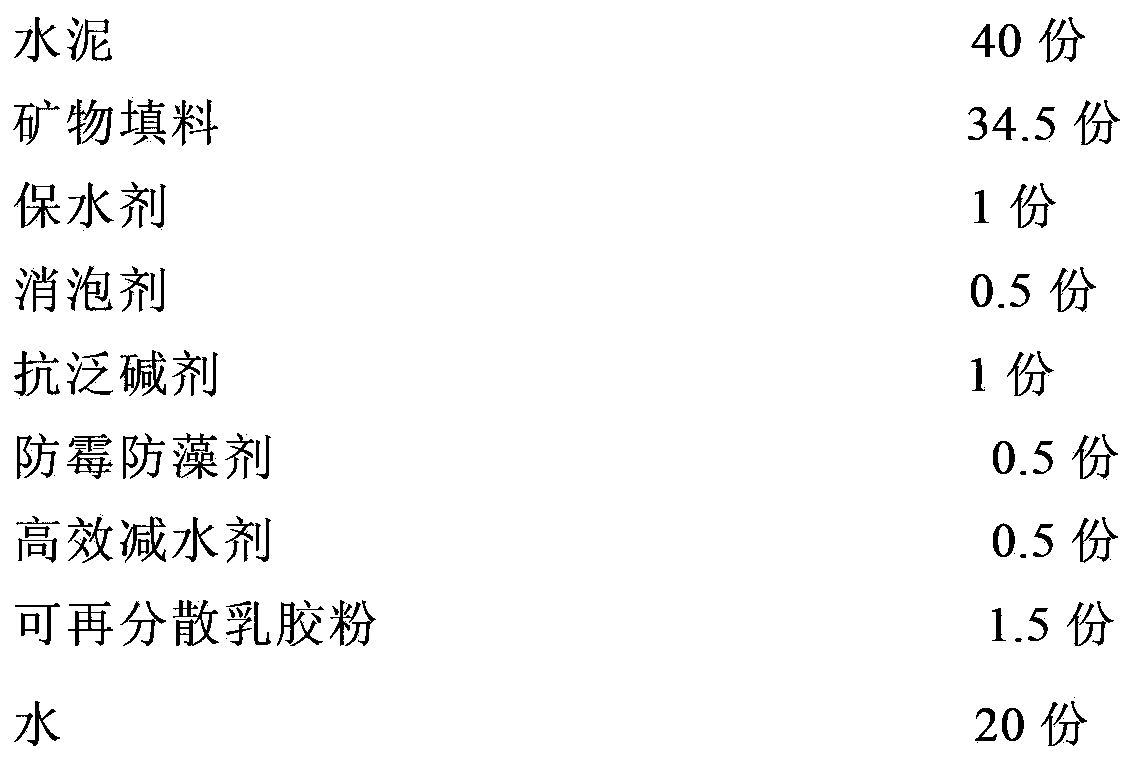

[0024] 2. Based on the above range, in the second embodiment provided by the present invention, the specific parts by weight of each component are as follows:

[0025]

[0026]

[0027] 3. Based on the above range, in the third embodiment provided by the present invention, the specific parts by weight of each component are as follows:

[0028]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap