Optical cable spreading burying machine

A technology for optical cables and cables, which is applied in the field of optical cable laying and embedding machines, can solve problems such as complex structure of optical cable embedding machines, inability to achieve synchronization, and affect laying quality, and achieve the effects of optimizing cutting effects, improving efficiency, and optimizing excavation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In the following, the present invention will be further described by using the following embodiments in conjunction with the accompanying drawings.

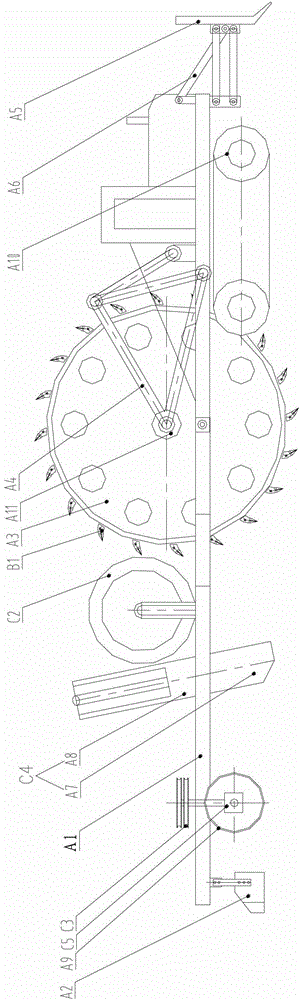

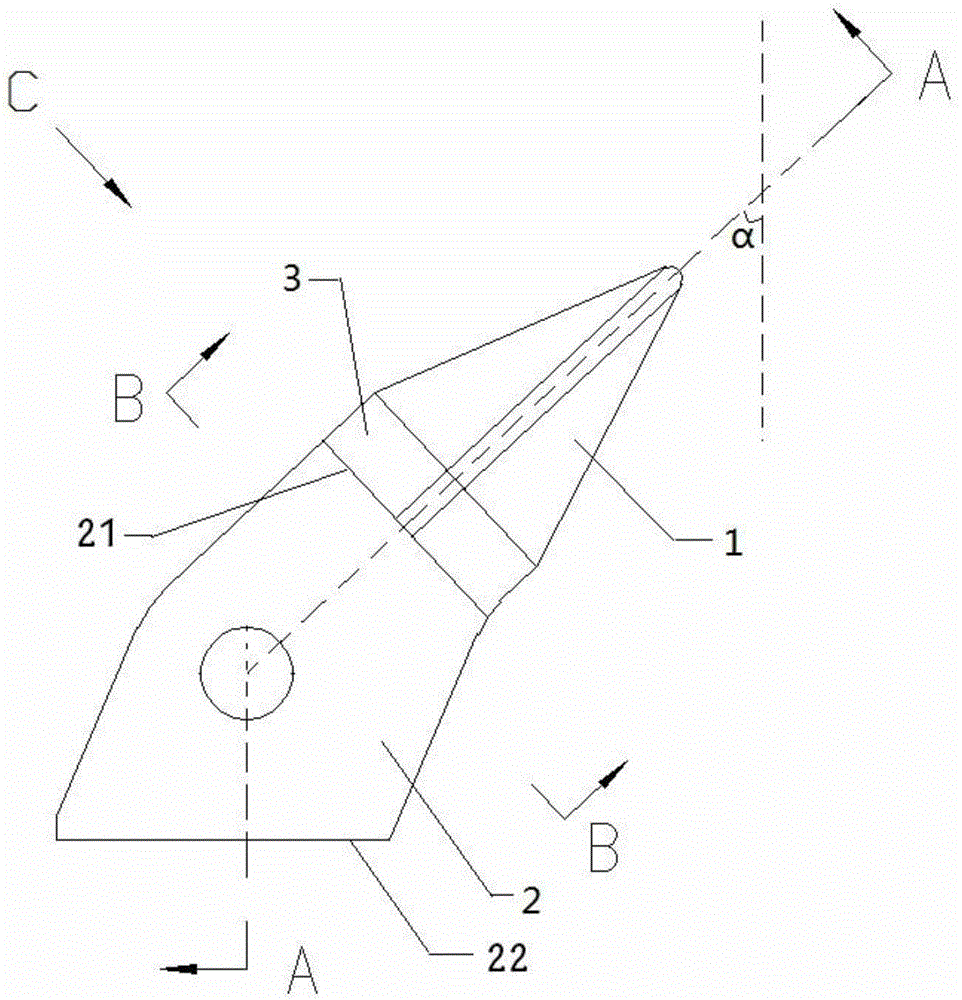

[0055] Such as figure 1 , 2 As shown, an optical cable embedding machine in this embodiment includes a trolley A1, a slotting device, a wire feeding device, an optical cable grounding device C4, and a soil covering device A2, wherein the slotting device includes a disc cutter A3, the traveling vehicle A1 is provided with a first hydraulic motor A10 for driving the traveling wheels or the traveling crawler;

[0056] The slotting device is provided with a second hydraulic motor A11 that drives the disc cutter A3 to rotate;

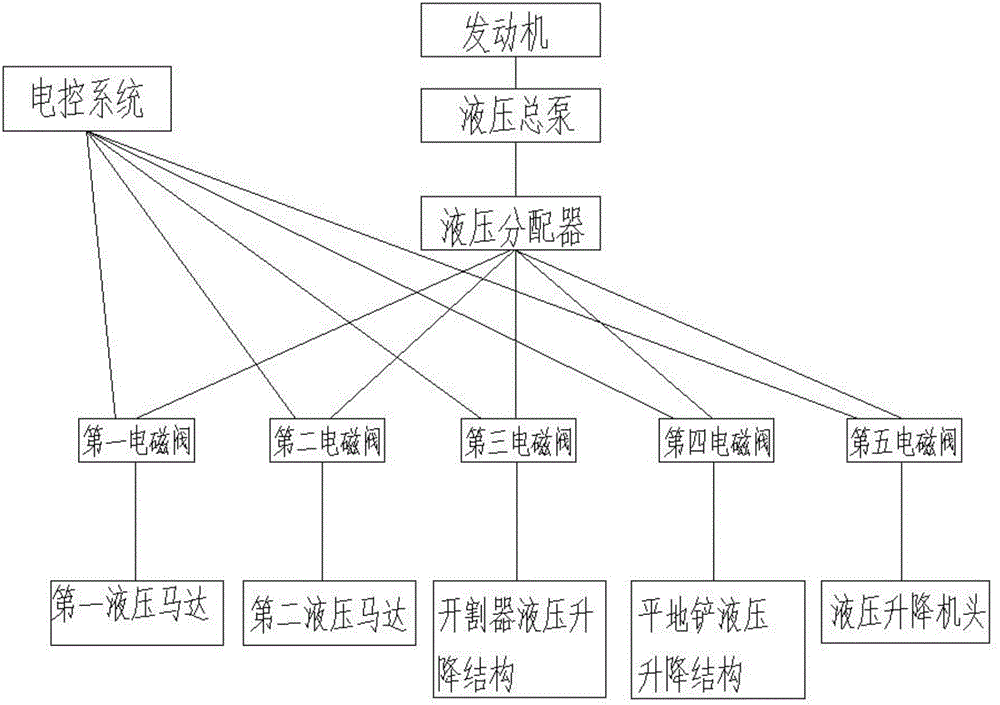

[0057] It also includes a power distribution device, the power distribution device includes a hydraulic master cylinder driven by the engine of the traveling vehicle A1, and distributes the high-pressure hydraulic oil of the hydraulic master cylinder to the first hydraulic motor A10, the second The hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com