Movable arm energy-saving control system

An energy-saving control system and boom technology, which can be applied to earth movers/excavators, construction, etc., can solve the problems of low energy utilization and achieve the effects of low cost, high efficiency and great development potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

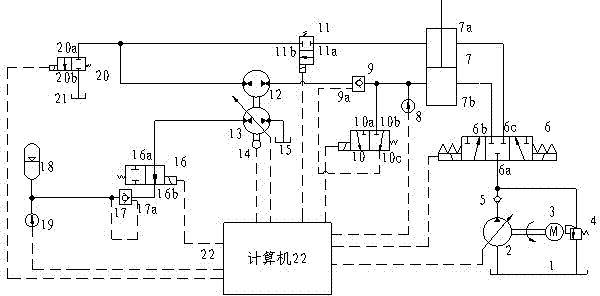

[0018] Such as figure 1 As shown, the present invention discloses a novel hydraulic excavator arm energy-saving control system, including a first oil tank 1, a variable pump 2, a motor 3, an overflow valve 4, a one-way valve 5, and a three-position three-way electromagnetic reversing Valve 6, the inlet of the variable variable pump 2 is connected to the first oil tank 1, the outlet is connected to the inlet of the one-way valve 5, the outlet of the one-way valve 5 is connected to the interface 6a of the three-position three-way electromagnetic reversing valve 6, and the one-way valve 5 is installed on The outlet of the variable pump 2, on the one hand, prevents the pressure of the system from impacting the normal operation of the image pump, and on the other hand, prevents the oil in the system from flowing back through the pump to the oil tank when the pump is not working. The motor 3 is used to drive the variable pump 2 to work. The bypass between the variable pump 2 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com