Formwork panel dismountable and thickness adjustable combined steel bar truss floor bearing plate

A reinforced truss, combined technology, applied in the direction of formwork/formwork/work frame, formwork/formwork/work frame connector, formwork treatment, etc., can solve the problems of waste of labor, damage, waste, etc. Broad market prospects, easy installation and disassembly, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

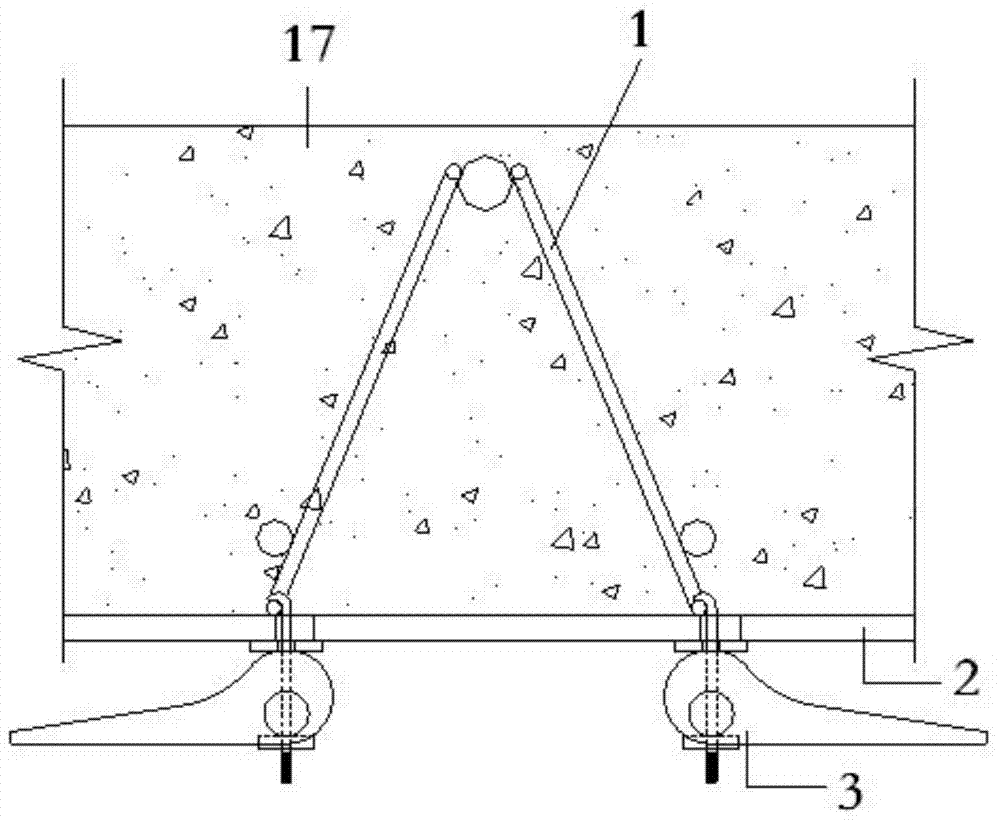

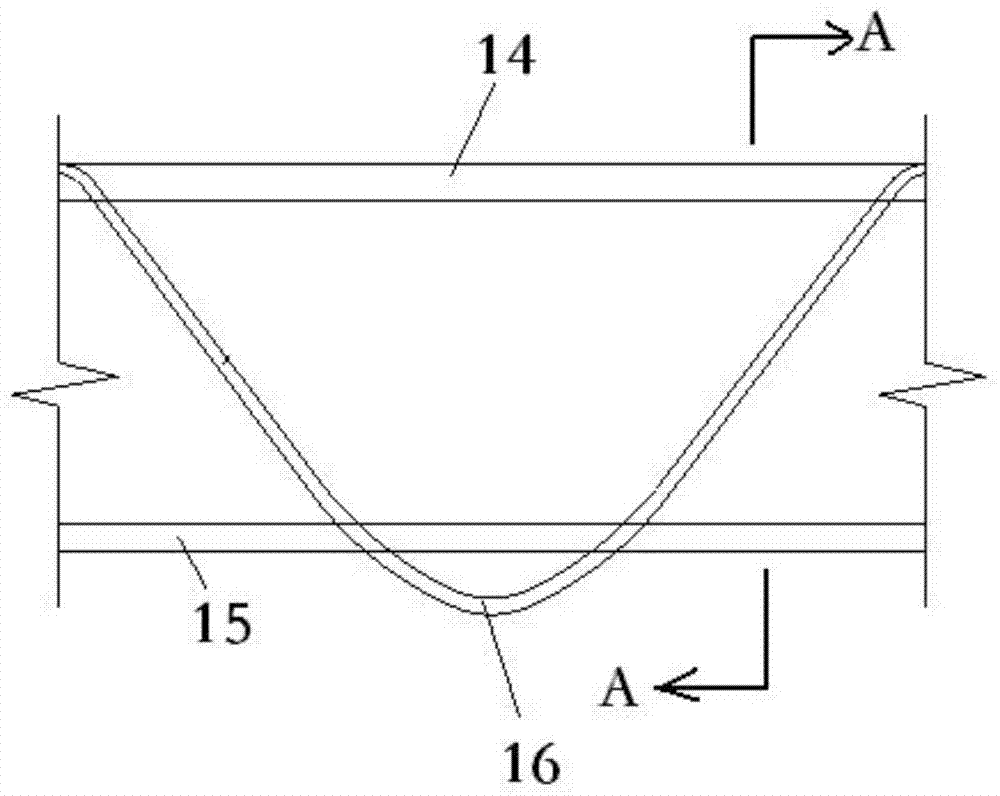

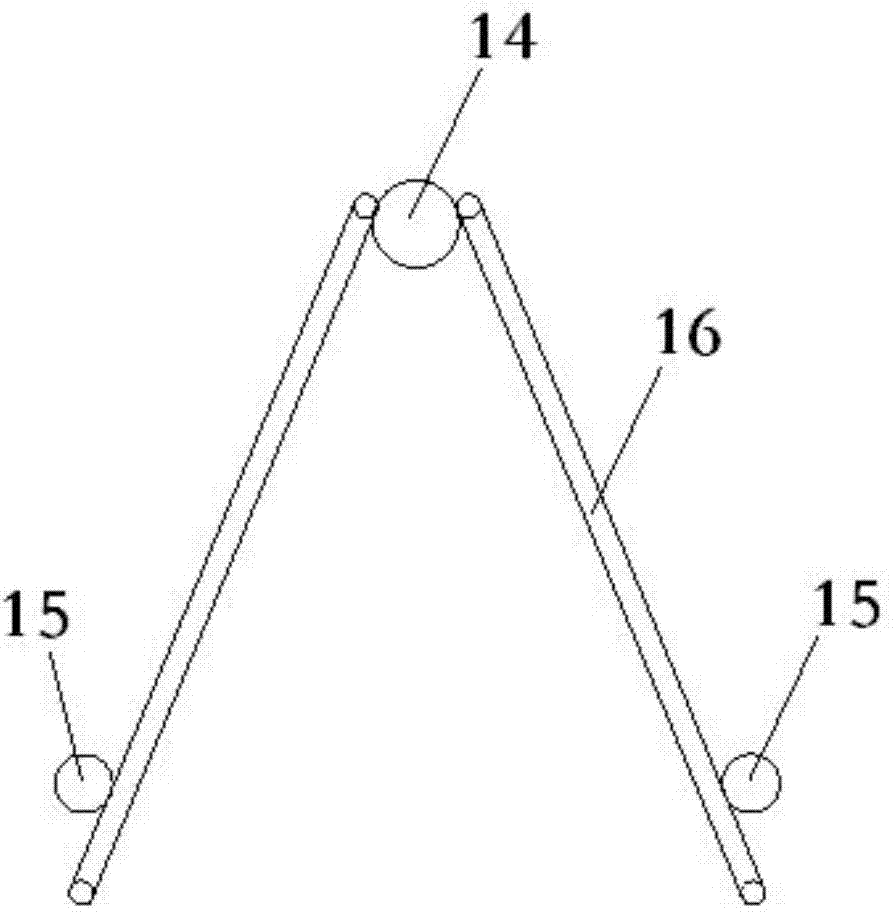

[0034] like Figure 1-8 As shown, a combined steel bar truss floor deck with detachable formwork panels and adjustable thickness, including: steel bar trusses 1, formwork panels 2 and supporting fasteners 3, characterized in that: the formwork panels 2 are provided with several The first through hole 4, the support fastener 3 passes through the first through hole 4 to connect the steel bar truss 1 and the template panel 2, the support fastener 3 includes a hook head 5, a support pad with holes 6. Connecting screw 7, adjusting nut 8, perforated force transmission steel shaft 9 and support wrench 10, the hook head 5 is connected to the top end of the connecting screw 7, the support wrench 10 includes an installation head 11 and a handle 12, the installation The head 11 and the handle 12 are seamlessly connected, and the installation head 11 is provided with a second thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com